Imagine a robotic arm that doesn't just mimic human movement, but surpasses it with an elegant, gravity-defying flip of its wrist – the "Tip Up" maneuver. This isn't science fiction; it's the core innovation driving a new generation of hyper-precise Robotic Instruments poised to revolutionize fields from microsurgery to mastering Mozart. While mainstream robotics focuses on brute force or repetitive tasks, the true breakthrough lies in achieving unprecedented dexterity and sensitivity. What if the key to unlocking this delicate touch lies not in raw power, but in a sophisticated, counter-intuitive motion? This article delves into the groundbreaking mechanics, transformative applications, and profound implications of Tip Up Robotic Instruments, revealing why mastering this subtle motion signals a giant leap for robotic finesse.

Demystifying the Tip Up Robotic Instrument: More Than Just a Flip

At its core, a Tip Up Robotic Instrument refers to a highly specialized robotic system, or a critical component thereof, designed to perform a controlled upward tilting motion at its end-effector (the "tip") with exceptional precision, speed, and often, controlled compliance. This specific "Tip Up" action differentiates it from standard robotic arms which primarily operate in linear or simple rotational planes.

Think of it like the human wrist's ability to rapidly tilt a violin bow upwards for a spiccato stroke, or a surgeon's flick of the wrist when making a micro-incision. The Tip Up mechanism isn't about lifting heavy loads; it's about achieving micro-scale positional accuracy, high-frequency articulation, and delicate interaction at the point of contact. This capability is paramount in applications demanding extreme dexterity exceeding human physiological limits.

The sophistication often lies in the integration of advanced actuators (like piezoelectric or voice-coil motors), low-inertia linkages, and precise torque control systems, allowing the "Tip Up" to be executed with minimal vibration and latency. The system is calibrated to understand its precise orientation relative to a task, and the Tip Up command becomes a fundamental movement primitive programmed for specific high-fidelity interactions.

Core Applications: Where the Tip Up Motion Makes Magic

The Sonic Revolution: Music Redefined

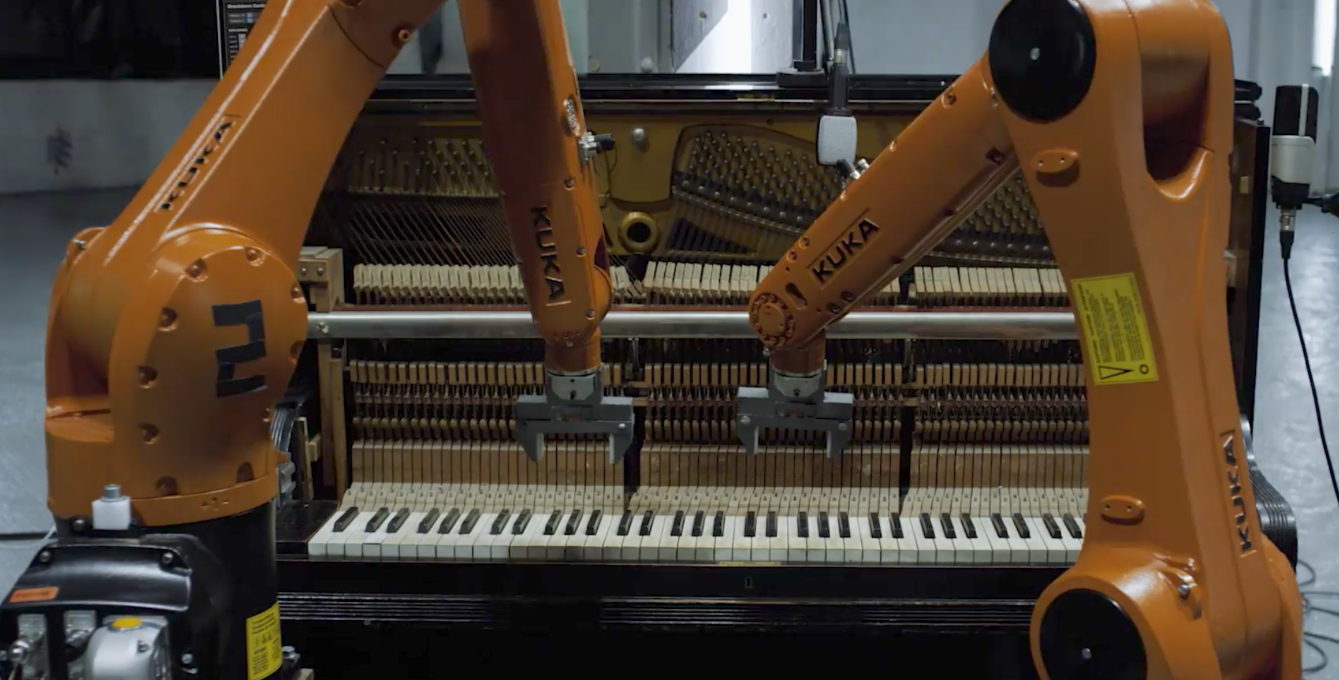

This is perhaps the most publicly captivating application. Traditional musical instrument playing relies heavily on nuanced wrist and finger movements. A Tip Up Robotic Instrument excels here:

String Articulation Perfection: For instruments like violin, cello, or guitar, the controlled Tip Up motion is essential for techniques like spiccato (bouncing the bow), precise pizzicato (plucking), and rapid string crossing. Robots equipped with this can execute these techniques with inhuman consistency and speed, exploring tempos and rhythmic patterns impossible for humans.

Percussive Precision: Playing instruments like vibraphone, marimba, or drums requires accurate mallet strikes with controlled rebound. The Tip Up action enables mallets to strike and cleanly lift off instantly, crucial for fast, clean passages and nuanced dynamics. This isn't just about hitting; it's about the controlled release. Discover more about AI's impact on creative frontiers in our article on Musical Instrument Robots: The AI-Powered Machines Redefining Music's Creative Frontier.

Wind Instrument Nuance (Future Frontier): While finger articulation is key for woodwinds, the Tip Up principle applies to potential robotic mechanisms controlling breath valves or reed pressure modulation with extreme speed and subtlety.

Laboratory & Medical Precision: Beyond Human Tremor

The Tip Up Robotic Instrument's value extends far beyond the concert hall:

Microscopic Manipulation: In life sciences and material science, handling delicate specimens under a microscope, manipulating cell cultures, or placing micro-components requires nanometer-scale stability and precise vertical adjustments. The controlled Tip Up allows probes or pipettes to gently touch and retract without inducing damaging vibrations or drag.

Robotic-Assisted Microsurgery: Surgical robots already enhance precision, but incorporating Tip Up mechanics into instruments like scalpels or forceps allows for previously impossible motions. Imagine a scalpel making an incision and instantly tilting up minutely to avoid deeper tissue, or forceps grasping tissue and slightly tilting to optimize tension during suturing, all controlled remotely by the surgeon with enhanced feedback.

Automated Micro-Assembly: Building miniature devices (MEMS, optics) often involves placing tiny components. A robotic picker with a controlled Tip Up action can place a component and gently tilt away without disturbing adjacent parts, crucial for densely packed electronics.

Advanced Manufacturing & Quality Control

Ultra-precision assembly lines are leveraging this technology:

Defect Inspection: A probe or sensor mounted on a Tip Up Robotic Instrument can scan a complex surface, rapidly tilting at angles to inspect holes, crevices, or undercuts without requiring bulky re-orientation of the entire arm.

Delicate Finishing: Applying final touches, polishing intricate contours, or removing microscopic burrs requires gentle tool interaction. The Tip Up mechanism allows tools to engage and disengage with surfaces at the optimal angle with minimal pressure variation.

Component Placement: Similar to micro-assembly, precision placement of fragile components on circuit boards or delicate mechanisms benefits from the gentle placement and clean disengagement afforded by the Tip Up action.

The Tip Up Robotic Instrument Architecture: Engineering Finesse

What makes a true Tip Up Robotic Instrument distinct from a robot that simply moves up? It's the dedicated engineering focused on performance:

| Component | Requirement | Role in "Tip Up" Performance |

|---|---|---|

| Joint Mechanism (Wrist/Linkage) | Ultra-low inertia, minimal backlash, high stiffness in other axes | Enables rapid acceleration/deceleration for the "up" tilt with minimal overshoot or oscillation. Must transmit force/position accurately. |

| Actuators | High bandwidth, precise torque control, often non-traditional (Piezo, VC) | Provides the muscle for rapid tilting with millisecond response times and force fidelity essential for delicate tasks. |

| Position & Torque Sensing | High-resolution encoders, miniature torque sensors at the tip | Provides closed-loop feedback to control the exact angle, speed, and force during the tilt. Detects contact instantly. |

| Control System | Real-time computing, advanced algorithms (impedance/admittance control) | Translates the high-level "tip up" command into precise motor currents, manages dynamics like vibration suppression, and handles interaction forces. |

| End-Effector Interface | Standardized (e.g., tool changers), low mass, rigid | Ensures quick attachment of specialized tools (bow, scalpel, probe) without compromising the dynamic performance or precision of the tip motion. |

The seamless integration of these elements defines a high-performance Tip Up Robotic Instrument. Its "wrist" isn't an afterthought; it's a marvel of mechatronic engineering dedicated to the nuance of tilting.

Human vs. Tip Up Robotic Instrument: The Dexterity Benchmark

How does robotic finesse truly compare to human capability? The Tip Up Robotic Instrument excels in quantifiable precision:

Speed & Frequency: Humans max out around 5-10Hz for very fast, controlled wrist tilts. Advanced Tip Up systems can achieve tilt/reposition cycles exceeding 50Hz consistently and indefinitely. This allows musical techniques played at impossible tempos or factory throughputs unimaginable manually.

Accuracy & Repeatability: While a skilled human can be very accurate, minute tremors (physiological tremor ~8-12Hz) are unavoidable. Robotic systems eliminate this. Precision in the micrometer or even nanometer range for tilt angle and position is achievable, with near-perfect repeatability crucial in manufacturing and surgery.

Endurance: Humans fatigue quickly performing high-precision, repetitive tilting motions. Repetitive Strain Injuries (RSI) are common. Robotic instruments operate continuously without degradation in performance.

Working Environment: Humans are limited by hazardous environments (extreme temperatures, vacuum, radiation). Tip Up Robotic Instruments can function in these hostile settings.

Nuance & Adaptability: *The Human Advantage (For Now)*: Humans possess superior real-time adaptability, sensory integration (touch, sound, proprioception fused intuitively), and the ability to improvise creatively based on unexpected feedback. Robotic systems are catching up rapidly through AI and ML (Machine Learning).

The key takeaway is that Tip Up Robotic Instruments surpass human capabilities in measurable, repeatable tasks demanding extreme speed and precision. They extend our reach into realms of scale and endurance previously impossible.

Explore the wider implications of this new robotic dexterity in music From Circuits to Cadenzas: How AI-Powered Robots Are Shattering Music's Glass Ceiling.

Calibrating Perfection: A Technical Tutorial

Maximizing the performance of a Tip Up Robotic Instrument hinges on meticulous calibration. This tutorial outlines critical steps:

1. Mechanical Zero Alignment (Referencing)

Objective: Define the absolute physical neutral position of the Tip Up joint.

Tools: Precision square, dial indicator, calibration block/jig supplied by manufacturer.

Procedure: Carefully follow manufacturer instructions. This often involves physically aligning a datum surface on the mechanism with a reference jig block or instrument and using indicator probes to find the true mechanical zero position. Record this position in the control system's joint space. Ignore sensor readings initially; this is purely about physical alignment.

2. Fine Position Sensing Calibration (Encoder Homing)

Objective: Synchronize the high-resolution joint encoder(s) with the physical zero defined in Step 1.

Tools: Control software interface.

Procedure: Execute the homing routine via the control software. This typically moves the joint slowly towards the mechanical zero position until a limit sensor is triggered. The system then establishes an index pulse from the encoder at this known position, linking encoder counts to physical angle. Verify the commanded zero angle matches the physical datum established in Step 1 (within micrometer tolerances).

3. Torque/Force Sensor Calibration (If Applicable)

Objective: Calibrate the relationship between measured electrical signals from any strain gauges or torque sensors and actual physical forces/torques at the tip.

Tools: Calibration weights (micro-gram to gram scale), precise calibration fixture.

Procedure: Apply precisely known static weights or torques in different axes to the end-effector attachment point. For multi-axis sensors, this is complex and requires specific fixtures applying pure forces/moments. Record the sensor outputs. Use the control software's calibration function to generate a transformation matrix mapping sensor readings to actual forces and torques. Test with known loads to verify accuracy post-calibration.

4. Dynamic Response Characterization & Vibration Suppression Tuning

Objective: Understand and dampen unwanted resonances during rapid Tip Up motions.

Tools: Accelerometer, control software with oscilloscope/frequency analyzer functionality.

Procedure: Secure a lightweight accelerometer near the instrument tip. Command the system to perform rapid "tip up" step movements. Analyze the response. Look for "ringing" (oscillation) after the move settles. Use software tools to identify the resonant frequency(ies). Adjust digital filters (Notch filters tuned to the resonance frequencies, or damping parameters in an advanced controller) to suppress these vibrations without significantly slowing down the overall response time. Iterate carefully. This step maximizes precision and minimizes settling time post-movement.

5. Task-Specific Compensation Calibration

Objective: Compensate for tool-specific mass, center of gravity shift, or friction in use cases.

Tools: Tool mounted.

Procedure: With the final tool attached, execute gravity compensation routines (if available) to account for tool weight affecting torque sensors. Test low-speed friction during the Tip Up motion; the controller may need friction compensation parameters tuned. Finally, perform target practice: command the tip to specific positions or track specific paths and measure deviation. Fine-tune controller gains for optimal trajectory following under load conditions relevant to your specific application (e.g., moving while in contact with a violin string).

The Future Tipped Up: Integration, AI & Ubiquity

The journey of the Tip Up Robotic Instrument is far from complete. Key trends point towards an even more transformative future:

Deep AI Integration: Imagine a surgical robot learning, via Machine Learning analysis of surgeon actions and tissue feedback, to subtly adapt the angle and force of its Tip Up scalpel motions during different procedures, optimizing for minimal invasiveness in real-time. Or, a musical robot learning, through Reinforcement Learning, the perfect tilt angle and acceleration profile for a specific spiccato effect desired by a composer on a particular violin. AI will enable these instruments to become context-aware partners, mastering subtlety in dynamic environments.

Miniaturization: Bringing true Tip Up precision down to the scale suitable for intracellular manipulation or micro-scale surgery is a frontier. Advances in micro-actuators and micro-sensors are critical.

Sensor Fusion & Haptics: Integrating rich sensory data (vision, force, tactile sensors capturing skin-like pressure distribution) combined with sophisticated haptic feedback will allow human operators to "feel" what the instrument tip feels, enabling teleoperation with an unprecedented sense of touch.

Cloud Calibration & Interoperability: Standardized communication protocols and potentially cloud-based calibration services could ensure consistent peak performance across fleets of instruments without requiring constant expert intervention onsite.

Cost Reduction & Accessibility: As core technologies mature, the cost of high-performance mechanisms will decrease, moving beyond niche labs and high-end surgery into more widespread industrial automation and potentially educational or prosumer settings.

The Tip Up Robotic Instrument represents a paradigm shift from robots as clumsy automata to instruments of unparalleled dexterity. It embodies the quest to give machines the finesse of the human hand and wrist, amplified by silicon and steel. Its growing ubiquity signals not the replacement of humans, but the augmentation of our capabilities to explore, create, and heal at scales never before imagined.

Frequently Asked Questions (FAQ): Tip Up Robotic Instruments

Q: How durable is a Tip Up Robotic Instrument? Won't constant tilting wear it out?

A: While mechanical components inevitably wear, the design minimizes this significantly. Key points:

High-precision bearings in the tilt mechanism are specified for millions of cycles under load.

Non-contact position sensing eliminates wear from sliding electrical contacts.

Advanced actuators like piezo ceramics have virtually no moving parts in the traditional sense, offering exceptional long-term stability.

Closed-loop control constantly compensates for minor changes (like thermal drift).

Predictive maintenance monitoring (vibration analysis, torque signatures) can flag potential issues before they impact precision, ensuring longevity.

Q: Can a Tip Up Robotic Instrument genuinely "improvise" creatively in music, or is it just playing programmed sequences?

A: Currently, the level of improvisation depends heavily on integration with AI:

Pre-Programmed: Most systems play compositions transcribed meticulously by humans for the robot.

Generative AI: More advanced setups use AI algorithms to generate note sequences and articulation in real-time based on style inputs or algorithmic rules. The robot faithfully executes these scores, including programmed "Tip Up" commands.

Reactive AI (Future): The frontier involves systems using real-time audio analysis and sensory feedback. Imagine a robot "listening" to ensemble members and subtly adjusting its own Tip Up timing, force, or bowing angle within programmed parameters to better blend or respond, creating a rudimentary form of robotic ensemble improvisation. True spontaneous "creativity" remains a complex philosophical and technical question.

Q: How accessible are these systems currently? Are we talking lab prototypes or commercially available products?

A: The accessibility spectrum is broad:

Cutting-Edge Research Prototypes: Universities and research labs develop the most advanced versions, pushing boundaries in speed, precision, and AI control.

Specialized Commercial Systems: Companies primarily serving high-end manufacturing (e.g., semiconductor) and life sciences (microscopy automation, specialized research instruments) offer sophisticated robotic manipulators that inherently or explicitly include high-performance "Tip Up" capabilities as part of their precision toolkit. These are expensive, niche products.

Emerging Music Robots: A handful of specialized companies and individual artists/engineers have built robotic systems capable of playing acoustic instruments that rely on principles akin to the Tip Up motion. These are primarily for artistic exploration and unique performances, commercially available but bespoke and costly.

Broader Future Market: As core technologies (actuators, sensors) become cheaper and AI control matures, we can expect components and systems featuring this precise articulation to trickle into more affordable industrial arms, specialized surgical tools, and potentially educational platforms.