Picture the deep, intricate mines of Tamil Nadu – rich in minerals like lignite, granite, and garnet sand. For generations, human hands, facing immense risk, have extracted these resources. But a silent revolution is unfolding beneath the earth. Mining Robot in Tamil applications are no longer sci-fi; they're rapidly emerging as the key to unlocking safer, more efficient, and sustainable mineral extraction, poised to transform the very fabric of this vital sector in the state. This article dives deep into this groundbreaking shift.

Why Tamil Nadu's Mines Need a Robotic Revolution

Tamil Nadu possesses significant mineral wealth. From the extensive lignite deposits of Neyveli to the famed granite quarries of Madurai and Kancheepuram, and valuable mineral sands along the coast, mining is economically crucial. However, the sector faces persistent challenges:

Safety Imperative: Underground mining, in particular, exposes workers to hazards like roof collapses, toxic gases, dust (leading to silicosis), and extreme conditions. Reducing human exposure is paramount.

Efficiency & Scale: Manual processes often limit output and speed. Increasing demand and global competition necessitate faster, more consistent extraction.

Environmental Stewardship: Tamil Nadu has rich biodiversity and densely populated areas. Precise mining techniques can minimize land disturbance, water contamination, and dust pollution.

Labor Shortages & Cost Pressures: Attracting skilled labor into tough mining environments is increasingly difficult, impacting operational costs and scaling efforts.

These intersecting pressures create the perfect environment for the adoption of Mining Robot in Tamil operations, offering tangible solutions.

What Exactly is a Mining Robot in Tamil Context?

The term "Mining Robot in Tamil" encompasses a diverse range of autonomous or semi-autonomous machines specifically designed or adapted to perform tasks traditionally done by humans in Tamil Nadu's mining environments. Key categories include:

Autonomous Haulage Systems (AHS): Massive dump trucks operating without drivers, navigating complex haul roads using GPS, LiDAR, and advanced sensors. Major players like Caterpillar and Volvo offer these globally.

Tele-Operated & Autonomous Drilling Rigs: Machines that drill blast holes or for exploration. Operators can control them remotely from safe locations, or they can function autonomously based on pre-programmed patterns and real-time sensor feedback.

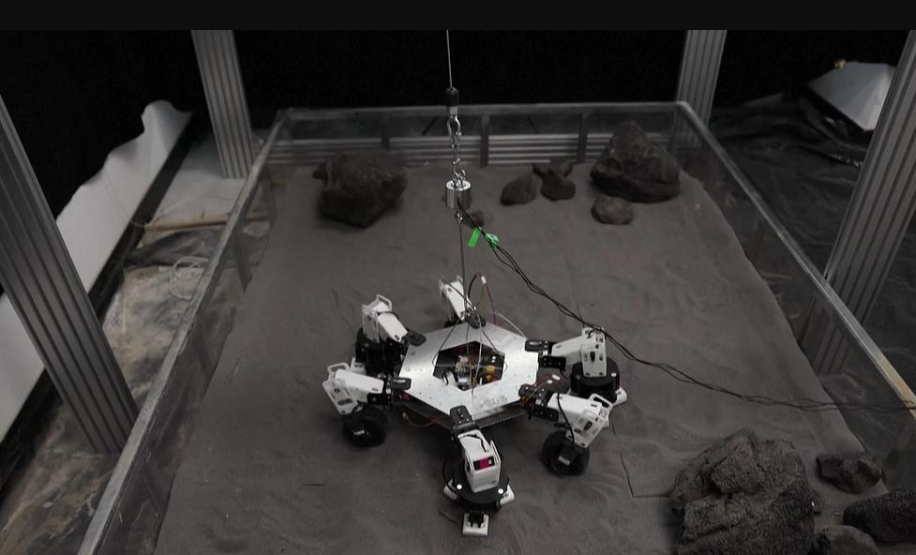

Exploration & Mapping Robots: Smaller, often tracked or legged robots equipped with sensors (cameras, LiDAR, spectrometers) used to map dangerous or inaccessible areas before large-scale operations begin. Learn more about the defining principles of Exploration Robotics in our dedicated article.

Inspection & Monitoring Robots: Drones (UAVs) for aerial surveys and stockpile management, and ground-based robots for inspecting tunnel integrity, checking for gas leaks, or monitoring equipment health.

Rock Breaking & Scaling Robots: Robotic arms mounted on vehicles, performing dangerous tasks like removing loose rocks from tunnel roofs (scaling) or precise rock breaking in controlled areas.

The Technologies Powering Mining Robot in Tamil Deployments

The success of these robots hinges on a suite of converging advanced technologies:

Artificial Intelligence (AI) & Machine Learning (ML): The "brains" enabling perception (object recognition), navigation (path planning), real-time decision making (obstacle avoidance), predictive maintenance, and optimizing operations like drill patterns. Understanding the core principles of Exploration Robotics is key here.

Sensors & Perception: LiDAR, radar, cameras (including thermal), inertial measurement units (IMUs), and gas sensors provide the robot with a detailed understanding of its surroundings in often dark, dusty, and GPS-denied environments.

Robust Connectivity (IoT): Reliable, high-bandwidth communication networks (including mesh networks and potentially 5G/Private LTE in designated areas) are essential for transmitting sensor data, control commands, and video feeds, especially for remote operation. Mines need significant infrastructure upgrades.

Advanced Battery Technology: For mobile robots, long-lasting, powerful, and potentially fast-charging (or hot-swappable) batteries are critical for sustained operations without frequent downtime.

Durability Engineering: Mining robots must withstand extreme conditions: dust, mud, water, vibration, impacts, corrosive environments, and temperature extremes. Harsh environment-rated components and rugged construction are non-negotiable.

Companies like Exploration Robotics Technologies Inc are at the forefront of developing these critical technologies specifically engineered for demanding exploration and mining tasks.

Real-World Impact: Benefits of Mining Robot in Tamil Applications

The integration of robotics promises profound benefits for Tamil Nadu's mining sector:

Revolutionizing Safety: The most significant impact. Removing humans from high-risk zones (deep pits, unstable faces, blast areas) drastically reduces accident rates and eliminates fatalities in robotic operations. Remote operation significantly enhances safety during rescue or inspection tasks.

Boosting Operational Efficiency: Robots don't tire, take breaks, or shift change immediately. Autonomous haul trucks can run 24/7, optimizing haul cycles. Drilling robots maintain precise patterns consistently. Overall equipment utilization (OEU) increases.

Enhanced Precision & Resource Recovery: AI-guided drilling and excavation can target ore bodies more accurately, minimizing waste rock extraction (reducing processing costs) and maximizing the recovery of valuable minerals from existing resources.

Data-Driven Decision Making: Robots generate vast amounts of real-time geological, operational, and maintenance data. Analyzing this with AI provides unprecedented insights for optimizing mine plans, predicting equipment failures (reducing downtime), and improving resource models.

Potential Environmental Gains: Precise operations reduce overburden removal and overall land disturbance. Potential for lower energy consumption per tonne moved with optimized operations. Reduced need for large on-site support facilities.

Unique Challenges for Implementing Mining Robot in Tamil Operations

The path to robotic mining in Tamil Nadu isn't without hurdles, some regionally specific:

High Capital Investment: The initial cost for advanced robotic systems (purchase, integration, infrastructure upgrades) is substantial, posing a barrier, especially for medium and small Tamil miners.

Technical Infrastructure Demands: Implementing robust, high-bandwidth, low-latency communication networks throughout complex mine sites, particularly deep underground, is a major engineering challenge. Power supply stability is crucial.

Workforce Transformation: While robots take over dangerous tasks, they create demand for new, higher-skilled roles: robotics operators, data analysts, maintenance technicians for complex systems, and AI specialists. Reskilling the existing workforce is critical and requires significant investment in training programs aligned with Tamil Nadu's educational institutions.

Regulatory & Legal Frameworks: Clear regulations governing autonomous operations underground, liability frameworks in case of system failures, safety certification standards for robotic systems, and cybersecurity protocols for critical infrastructure are still evolving in India and need state-level adaptation.

Navigating Local Conditions: Adapting global robotic solutions to the specific geology, climate extremes, and operational practices common in Tamil Nadu mines requires customization and testing.

The Road Ahead for Mining Robot in Tamil Nadu

The future trajectory is clear, but requires strategic action:

Phased Adoption: Initial focus will likely be on tele-remote operation for the most hazardous tasks (like drilling in deep pits or face dozing) and autonomous haulage in open-pit mines like lignite operations.

Hybrid Models Dominating: For the foreseeable future, fully autonomous mines are unlikely. Human-robot collaboration, where humans supervise, manage, and handle complex problem-solving while robots perform defined, repetitive, or dangerous tasks, will be the dominant model.

Data as the New "Mineral": Mines that effectively collect, manage, and analyze the data generated by robotic systems will gain a significant competitive advantage through optimized operations and predictive insights.

Focus on Skilling: Developing specialized training programs in partnership with Tamil Nadu's technical universities and polytechnics will be vital. Curricula need to focus on mechatronics, robotics operation, AI fundamentals for mining, and data analytics.

Government-Industry Collaboration: Creating supportive policies, funding for R&D/test-beds (potentially in collaboration with IITs), and clear, forward-looking regulations is essential to foster innovation and responsible adoption.

Conclusion: A Transformative Era Beckons

The integration of Mining Robot in Tamil operations represents a pivotal shift for Tamil Nadu's vital mining industry. It's not about replacing humans entirely, but rather about augmenting human capability and drastically improving safety standards in one of the world's most challenging professions. While the initial hurdles are significant, the long-term benefits – safeguarding lives, boosting efficiency, optimizing resource use, and potentially reducing environmental footprints – are compelling. By proactively addressing the challenges of investment, infrastructure, skilling, and regulation, Tamil Nadu can position itself at the forefront of responsible and technologically advanced mining, securing the sector's future prosperity and sustainability for decades to come.

Frequently Asked Questions (FAQs) About Mining Robot in Tamil

1. Are Mining Robot in Tamil applications actually being used in Tamil Nadu right now?

While not yet ubiquitous, trials and initial deployments are starting. Large corporations operating lignite mines or major granite quarries are more likely early adopters, exploring autonomous haul trucks and tele-operated drilling, primarily for safety enhancements. Widespread adoption requires significant infrastructure investment and regulatory evolution.

2. What happens to the jobs of existing Tamil mine workers if robots take over?

Robotics will fundamentally change the workforce, not necessarily eliminate it in the short term. Dangerous manual jobs (like blast hole loading or direct face work) will diminish. However, new high-demand roles will emerge: robotics operators (remote operators), maintenance technicians specialized in AI and robotics systems, data analysts for operational optimization, and safety supervisors monitoring robotic fleets. Proactive reskilling and training programs are crucial to transition the workforce.

3. Can small-scale mines in Tamil Nadu afford Mining Robot in Tamil technology?

The high upfront cost is currently a major barrier for small-scale miners. Solutions might emerge through:

Robot-as-a-Service (RaaS) models: Companies leasing robots/autonomy kits to miners for specific tasks or periods, reducing initial capital expenditure.

Cooperative Purchasing: Groups of small miners pooling resources to acquire shared robotic equipment.

Government Subsidies & Grants: Potential schemes focused on safety improvements or technological modernization for smaller operators.

Affordable solutions will take time and innovation.

4. How do Mining Robot in Tamil operations handle complex, unstructured underground environments?

This is a significant technical challenge. Advanced solutions use:

Multi-Sensor Fusion: Combining LiDAR, radar, cameras, and inertial navigation for robust perception where GPS fails.

Simultaneous Localization and Mapping (SLAM): Algorithms allowing robots to build maps of unknown environments while tracking their own location within them.

AI-Powered Navigation: Machine learning algorithms trained to recognize obstacles, understand tunnel structures, and plan paths in dynamic settings.

Robust Mechanical Design: Enhanced traction systems, articulated bodies, and sometimes legged locomotion for uneven terrain.

Performance in such extreme environments continues to improve but remains an active R&D area.