In today’s fast-paced industry, New Robots are reshaping production lines worldwide. From streamlined assembly to error-free quality checks, these New Robots bring unmatched efficiency. Companies that embrace New Robots see dramatic cost savings and faster output. Let’s explore how these intelligent machines optimize operations.

New Robots and AI-Driven Automation

AI-powered New Robots analyze data in real time. They adjust speed, pressure, and alignment to reduce defects. Studies show AI-driven automation can cut manufacturing costs by up to 30%.

These New Robots operate 24/7 without fatigue. They detect anomalies faster than human operators. By minimizing downtime, factories maximize output and profits.

Expert Insight

“Implementing AI New Robots changed our plant’s performance overnight,” says Maria Lopez, Plant Manager at TechFab Inc. “We saw a 25% throughput increase within weeks. The ability of these New Robots to learn and adapt makes all the difference.”

Use Cases: From Tesla to Universal Robots

Tesla’s factories leverage New Robots 2024 models for battery assembly. Every component is welded and inspected by New Robots with extreme precision. This approach supports fully automated lines.

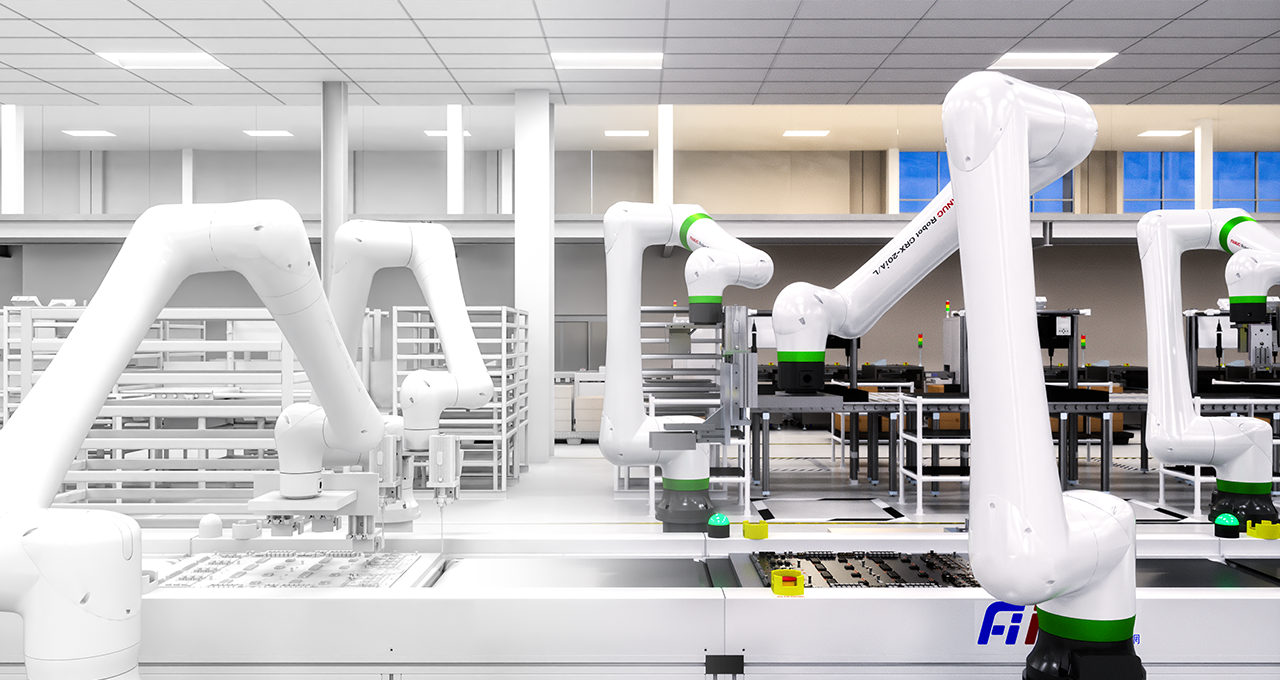

Meanwhile, Universal Robots’ cobots work alongside humans. These collaborative New Robots handle repetitive tasks, freeing staff for creative problem solving. They are safe, flexible, and easy to program.

Global Expansion of New Robots

China is investing heavily in New Robots in China, aiming to lead the industrial robotics market. Europe and North America follow closely with incentives for automation.

Boston Dynamics’ latest Boston Dynamics New Robots feature advanced mobility. These agile machines navigate complex factory floors, performing inspections and material transport.

Case Study: Tesla’s Fully Automated Line

At Tesla’s Fremont plant, New Tesla Robots manage the entire body-in-white process. Robotic arms lift, weld, and seal chassis components without human intervention. This reduces cycle time by 40% and scrap rates by 15%.

Point Analysis

Efficiency: Continuous 24/7 operation elevates output.

Quality: AI vision systems catch errors under 0.1%.

Flexibility: Quick reprogramming for new models.

Benefits and Challenges of New Robots

Major benefits include consistent performance, reduced labor costs, and data-driven insights. Factories equipped with New Robots report up to 50% fewer errors.

However, integration poses challenges. Staff need training to manage and maintain advanced systems. Initial investment can be high, but ROI often arrives within two years.

Future Outlook for New Robots

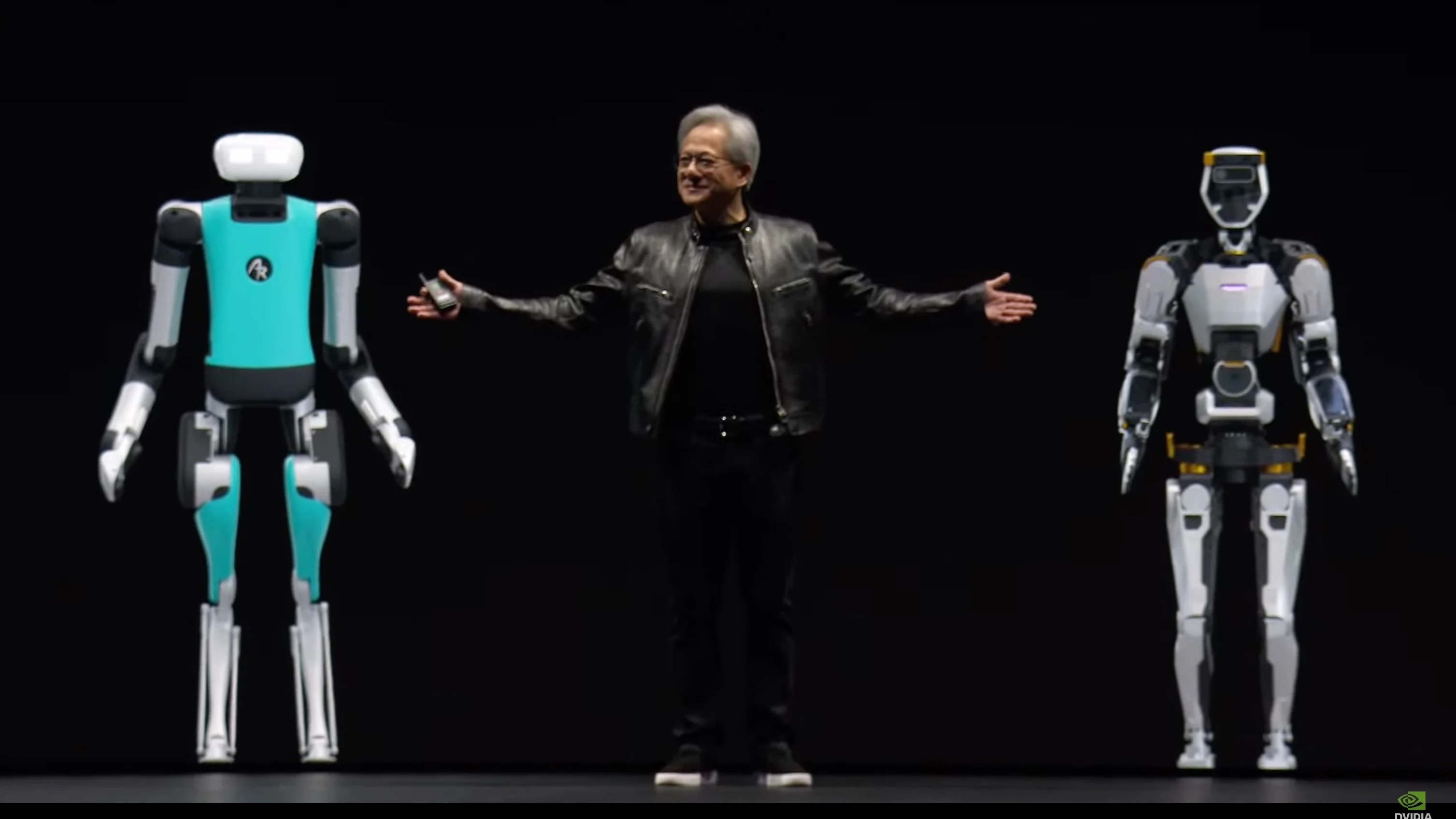

Emerging trends include humanoid assistants and self-organizing production cells. Companies like OpenAI explore AI frameworks to further enhance New Robots decision-making.

Expect to see Elon Musk New Robots concepts enter pilot stages soon. These next-gen machines will blur lines between factory and laboratory automation.

FAQs

1. What are New Robots?

New Robots are cutting-edge machines that use AI and sensors to automate manufacturing tasks with high precision.

2. How much can New Robots save?

On average, factories using New Robots report cost reductions up to 30% through lower labor and error rates.

3. Are New Robots safe around people?

Collaborative New Robots use force sensors and vision to halt if they detect human presence, ensuring safe interactions.

4. Where can I buy New Robots?

Major vendors include Universal Robots, Boston Dynamics, and Tesla’s manufacturing arm for specialized New Robots for Sale.