Imagine perfectly decorated, intricately designed cookies emerging with flawless consistency, batch after batch, without a single tired hand or moment of artistic frustration. This is no longer a fantasy confined to high-tech bakeries; it’s the new reality brought to us by automation. A Cookie Decorating Robot represents a fascinating fusion of culinary art and cutting-edge robotics, promising to transform a tedious, skill-demanding process into a streamlined, precise, and endlessly creative operation. This article delves deep into the world of these automated pastry chefs, exploring how they work, their immense benefits for bakers of all scales, and what their existence signals for the future of food technology and creative AI.

What is a Cookie Decorating Robot and How Does It Actually Work?

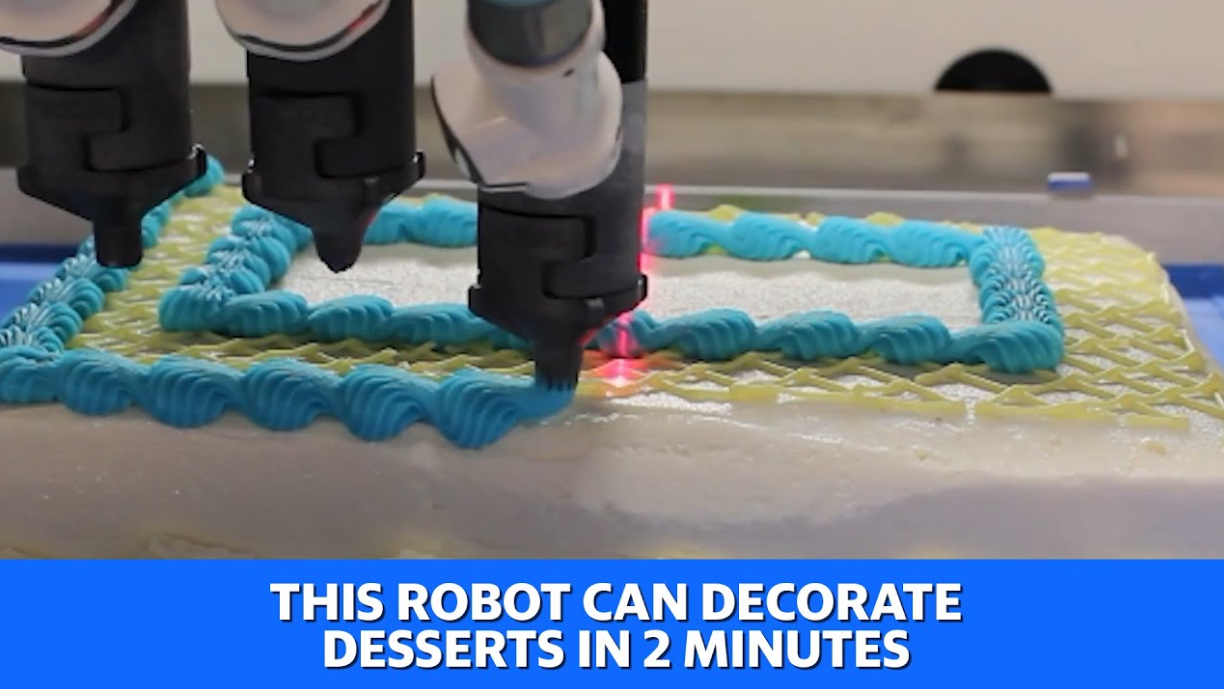

At its core, a Cookie Decorating Robot is a specialized robotic system, often built upon a multi-axis robotic arm, designed to replicate and exceed the delicate task of applying icing, frosting, and intricate designs onto cookies. Unlike a human decorator, its precision is measured in sub-millimeters, and its consistency is absolute. The system typically integrates several key components: a high-resolution vision system that scans and maps each cookie's position and surface, a sophisticated software suite where designs are created or uploaded, and a dispensing system that acts as its "decorating hand," controlling the flow of icing with pneumatic or mechanical precision.

The process begins with the vision system. Cameras capture an image of each plain cookie on the production line, identifying its exact orientation and any unique characteristics. This data is fed to the robot's controller, which adjusts the pre-programmed design path in real-time to ensure perfect alignment. The robotic arm then moves with astonishing speed and accuracy, following the digital design blueprint. The icing dispenser, akin to a high-tech pastry bag, lays down lines, fills areas, and even creates complex multi-layer designs with different colors, all without ever needing a break. This marriage of machine vision, path-planning algorithms, and precise motion control is what separates a simple automated dispenser from a true Cookie Decorating Robot.

The Software Brain: From Digital Design to Edible Art

The true magic of a Cookie Decorating Robot lies in its software. Users can design directly on a digital canvas, often using a simple drag-and-drop interface or by importing vector graphics (like SVG files) for limitless creative possibility. The software allows for layering, color assignment to specific icing reservoirs, and precise control over line thickness and fill patterns. For businesses, this means brand logos, custom messages, and incredibly detailed images can be reproduced on a cookie with perfect fidelity every single time, turning a baked good into a personalized marketing tool or a unique edible gift.

Beyond Perfection: The Tangible Benefits of Automating Decoration

The advantages of employing a Cookie Decorating Robot extend far beyond just achieving pretty cookies. For small boutique bakeries, the robot acts as a force multiplier, allowing the head pastry chef to focus on recipe development and business growth while the machine handles the time-consuming, repetitive task of decorating. It drastically reduces the training time needed for new employees, as operating the machine's software requires less innate artistic skill than handling a piping bag. The consistency it provides is a powerful tool for building brand reputation; customers come to expect and trust the flawless quality of every purchase.

For larger-scale operations, the benefits are measured in throughput and yield. A Cookie Decorating Robot can operate 24/7 without fatigue, significantly increasing production capacity, especially during peak seasons like holidays. It minimizes waste by using icing with optimal efficiency and drastically reduces the number of "seconds" or rejected cookies due to human error in decoration. This leap in efficiency and reduction in material and labor costs provides a compelling return on investment, making it a strategic upgrade for forward-thinking food manufacturers. This evolution in baking dovetails with other advancements, such as the technology behind witnessing a robot baking a cake from scratch, painting a picture of a highly automated kitchen future.

The Human Touch vs. The Machine Precision: A Collaborative Future

A common concern is the replacement of human artisans. However, the more likely future is one of collaboration, not replacement. A Cookie Decorating Robot excels at precision, repetition, and scale. It is the ideal tool for producing the bulk of an order with perfect uniformity. The human baker, freed from this repetitive task, can then focus on what machines cannot: genuine creativity, complex flavor development, and the art of hand-crafting truly one-of-a-kind showpiece items. The robot handles the tedious work, while the artisan focuses on innovation and high-touch customization, ultimately elevating the entire craft.

Integrating a Cookie Decorating Robot Into Your Baking Workflow

Adopting this technology requires thoughtful integration. The process typically follows these steps: First, baked and cooled cookies are placed on a tray or conveyor belt that feeds into the robot's work envelope. The robot's vision system identifies them, and the decoration cycle begins. After decoration, the cookies are moved to a drying or setting area before packaging. Successful integration means optimizing this entire flow, ensuring the robot's speed is matched by the preparation and post-processing stages to avoid bottlenecks. Training staff to use the design software is crucial to unlocking the machine's full potential.

Frequently Asked Questions About Cookie Decorating Robots

1. How much does a commercial Cookie Decorating Robot cost?

Entry-level systems for small businesses can start in the range of 15,000 to 30,000. High-end, fully integrated systems for large-scale production can cost $75,000 or more. The price is influenced by factors like speed, precision, the number of color channels, and the sophistication of the vision system.

2. Can it replicate any design I can imagine?

Virtually yes, as long as it can be translated into a digital vector graphic. The software allows for immense creativity with colors and patterns. However, extreme 3D decoration or techniques requiring physical manipulation of the icing after deposition may still require a human touch.

3. Is it difficult to clean and maintain?

Modern systems are designed with food safety and ease of maintenance in mind. The icing dispensing systems are typically designed to be easily disassembled for cleaning, similar to professional pastry bag tips. Regular maintenance involves lubricating moving parts and checking calibration, much like any other precision machinery in a kitchen.

4. Does the robot require a special type of icing?

Most robots are designed to work with standard royal icing or fondant, but the viscosity is critical. The icing must be fluid enough to flow consistently through the dispenser but thick enough to hold its shape after being applied. Users often need to work with the robot manufacturer to perfect their recipe for optimal performance.

The Icing on the Cake: A Sweet, Automated Future

The Cookie Decorating Robot is more than a novelty; it is a testament to how AI and robotics are permeating every facet of our lives, even the most creative and traditional ones like baking. It addresses real-world business challenges like labor shortages, quality control, and scaling production. By embracing this technology, bakers are not abandoning their craft; they are augmenting it, pushing the boundaries of what is possible in terms of design, scale, and efficiency. The future of baking is shaping up to be a beautiful partnership between human creativity and machine precision, ensuring that our favorite treats are not only delicious but also works of perfect, edible art.