Imagine a world where the intricate, delicate art of cake decorating is performed with machine-like precision, yet retains the soul of a master pastry chef. This is no longer a fantasy. The fusion of culinary arts and advanced robotics has given birth to the Cake Decorating Robot, a technological marvel that is reshaping patisseries and large-scale bakeries. This article delves deep into the fascinating mechanics, the sophisticated software, and the real-world impact of these automated artists, answering the burning question: how does a Cake Decorating Robot actually work?

The Core Components: Deconstructing the Cake Decorating Robot

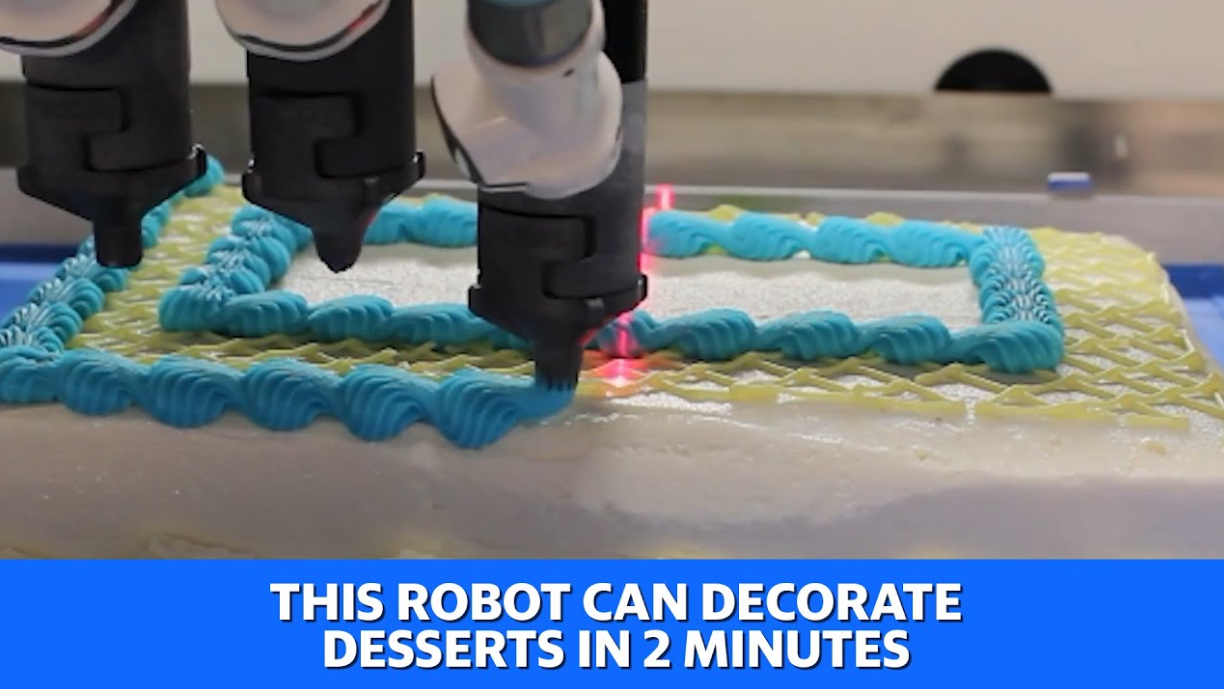

At its heart, a Cake Decorating Robot is a complex system integrating hardware and software. It's far more than a simple machine; it's a coordinated ensemble of precision components. The primary hardware consists of a multi-axis robotic arm, typically with five or six axes of movement. This arm provides the dexterity needed for complex piping and detailing, mimicking the full range of motion of a human wrist and hand. Attached to this arm is an end-effector, which is the tool that holds the piping bag or other decorating implements. This isn't a standard bag; it's often a specialized, pressurized cartridge system that holds different colors and consistencies of icing, fondant, or even chocolate, allowing for rapid, clean changes without any manual intervention.

The robot operates on a stable platform or within a contained work cell for safety and hygiene. A high-resolution vision system, often a camera, acts as its eyes. This camera scans the cake's position and surface, creating a digital map to ensure absolute accuracy. This is crucial for aligning pre-designed patterns perfectly onto the sometimes-uneven surface of a cake. The entire operation is powered by a control unit, a powerful computer that translates digital designs into physical movements with incredible accuracy, often down to a fraction of a millimeter.

The Digital Brain: From Design to Delicious Execution

The true magic of a Cake Decorating Robot lies in its software. The process begins not in the kitchen, but on a computer screen. A decorator or designer uses specialized software to create or upload a design. This could be a intricate lace pattern, a company logo, a photorealistic image, or even a 3D model for more advanced systems that build structures with icing. The software then converts this visual design into a set of precise coordinates and a toolpath—a detailed instruction set for the robotic arm.

This toolpath dictates every single movement: the speed, the angle of approach, the amount of pressure applied to the icing bag, and the precise points where the icing should be deposited. It's the equivalent of a GPS route for the robot, telling it exactly how to get from point A to point B while creating the desired pattern. This digital workflow ensures perfect replication every single time. A single design file can be used to decorate hundreds of cakes, and each one will be an identical masterpiece, a feat nearly impossible to achieve consistently by hand.

A Step-by-Step Workflow: Witnessing the Robot in Action

Understanding the individual components is one thing, but seeing them work in harmony is where the real understanding begins. The operation of a Cake Decorating Robot follows a meticulous, efficient sequence. First, a human operator places a pre-baked and pre-crumb-coated cake onto the designated work platform within the robot's cell. The operator then selects the desired design from the software library. Upon initiation, the robot's vision system springs into action. It scans the cake to determine its exact position, orientation, and height, making micro-adjustments to the pre-programmed toolpath to account for any minor misplacement or irregularity in the cake's surface.

With the cake mapped, the robotic arm moves to its starting position. It picks up the designated icing cartridge—perhaps starting with a base color—and begins its work. Following the digital toolpath with unerring accuracy, it pipes the design layer by layer. It can change cartridges automatically from a carousel holding multiple colors, pausing only for a quick purge of the previous color to ensure purity. The movements are fluid, efficient, and mesmerizingly precise. For a complex design, this process might take several minutes, but it is completed without a single tremor or mistake. Once finished, the arm resets, and the perfectly decorated cake is ready for presentation or packaging. This process is a fascinating parallel to other automated culinary feats, such as The Sweet Future: Witnessing a Robot Baking a Cake From Scratch.

Human vs. Machine: The Unbeatable Advantages of Robotic Decoration

The adoption of this technology is driven by a host of compelling advantages that address key challenges in the food industry. The most obvious benefit is unparalleled consistency and precision. A Cake Decorating Robot eliminates human error and variability. Every cake is a perfect replica of the digital design, ensuring brand consistency for bakeries and a flawless product for customers. This level of quality control is simply unattainable over large production runs with human decorators who naturally experience fatigue.

Secondly, these robots bring immense scalability and speed to production. They can operate 24/7 without breaks, dramatically increasing output capacity, especially during peak seasons like holidays and weddings. This allows businesses to fulfill large orders that would be logistically impossible or prohibitively expensive to complete by hand. Furthermore, they address significant labor challenges. By automating a highly skilled but repetitive task, they free up master pastry chefs to focus on innovation, recipe development, and other creative aspects that machines cannot replicate, thus adding more value to the business.

Beyond the Hype: Current Limitations and the Irreplaceable Human Touch

Despite their impressive capabilities, it's crucial to understand that Cake Decorating Robots are tools, not replacements. Their current limitations are defined by their programming. They excel at executing pre-defined patterns but lack the spontaneous creativity, intuition, and adaptive problem-solving skills of a human artist. A robot cannot look at a cracked cake and creatively design a pattern to hide the flaw; it will simply execute its program over the crack.

The initial investment is also substantial, placing this technology primarily within the reach of large-scale commercial bakeries, high-volume franchises, and specialized contract decorators. For a small local bakery, the cost is often unjustifiable. Most importantly, these robots cannot understand emotion, narrative, or the personal touch that is so often central to a custom cake. The story a human decorator weaves into a wedding cake or a birthday cake is a form of art that, for now, remains firmly in the human domain. The robot is the flawless executor, but the human remains the visionary creator.

Frequently Asked Questions

Can a Cake Decorating Robot create 3D figurines and structures?

Yes, advanced models are capable of 3D decoration. They use a thicker, quick-setting medium like royal icing or chocolate to build structures layer by layer, similar to 3D printing. The robot calculates the structure's stability and deposits the material in a way that allows each layer to support the next, creating stunning edible sculptures.

How do you clean a Cake Decorating Robot to maintain food safety?

Hygiene is paramount. The end-effector and icing cartridges are designed to be easily detachable for thorough cleaning and sanitization. Many components are dishwasher-safe. The work area is typically made of easy-clean stainless steel. High-end systems may even feature automated cleaning cycles that flush the piping lines with food-safe sanitizers.

What file formats does the design software typically use?

Most systems accept common vector file formats like .SVG (Scalable Vector Graphics) and .AI (Adobe Illustrator). Vector files are ideal because they contain mathematical paths that can be scaled to any size without losing quality, allowing a design to be perfectly adjusted to any cake dimension. Some systems also accept high-resolution .PNG or .JPG images.

The Future is Iced: What's Next for Automated Decorating?

The evolution of the Cake Decorating Robot is far from over. We are moving towards more integrated systems where the baking and decorating processes are fully connected. AI and machine learning are the next frontiers. Imagine a robot that can scan a cake and autonomously correct minor imperfections or suggest design adjustments. Future systems might even be able to analyze trends from social media to generate novel, on-demand designs, creating a new form of data-driven pastry art. The collaboration between human creativity and robotic precision is set to define the future of gastronomy.