The Robot Revolution Starts Here: What is an Instrument For Making Robot?

Picture holding the ultimate creative toolkit where circuits become cognition and code transforms into movement. This is the power of an Instrument For Making Robot – a specialized framework enabling creators to design, prototype, and deploy intelligent machines without decades of engineering experience. These instruments democratize robotics, merging intuitive interfaces with industrial-grade capabilities.

Unlike singular robotic products, they function as modular ecosystems where sensors, actuators, AI brains, and development environments interlock like orchestra sections. This transforms conceptual sketches into functional robots addressing real-world challenges in manufacturing, healthcare, exploration, and artistic expression. The core philosophy? Democratizing innovation by lowering technical barriers.

The term extends beyond physical toolkits. Cloud-based simulation platforms qualify as digital Instrument For Making Robot, where algorithms test behaviors before hardware exists. Similarly, open-source software libraries specializing in robot kinematics or computer vision are computational instruments accelerating development.

Why Instrument For Making Robot is Disrupting Innovation Cycles

Historically, developing functional robots demanded specialized knowledge spanning mechanical engineering, embedded systems, and AI – siloed expertise requiring years to master. Modern Instrument For Making Robot collapses these timelines dramatically. Platforms like NVIDIA Isaac Sim offer photorealistic simulation environments where reinforcement learning algorithms train robots in days instead of months.

Open-source frameworks like ROS (Robot Operating System) provide pre-tested communication protocols, eliminating low-level coding for sensor integration. Crucially, instruments prioritize rapid iteration – a critical advantage over traditional methods.

Consider Boston Dynamics' evolution: early models took years per iteration using custom development stacks. Contrast this with contemporary startups deploying warehouse robots in under 12 months using modular instruments like Viam or Open Robotics. This acceleration stems from three pillars: reusable code modules, interoperable hardware, and emulation ecosystems.

Exploring Instrument Ecosystems: From Modular Kits to AI Brains

Physical Instrument Kits

Tangible Instrument For Making Robot platforms fall into two categories. Educational kits like LEGO MINDSTORMS or VEX Robotics emphasize accessibility with snap-together components ideal for classrooms. These systems feature pre-configured microcontrollers, servo motors, and environment sensors paired with block-based coding interfaces.

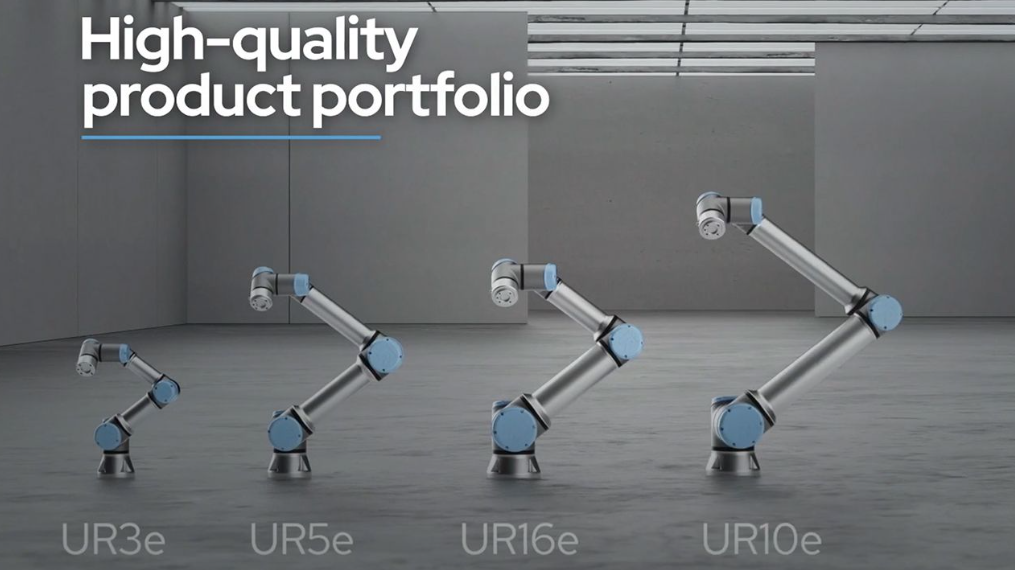

Conversely, industrial-grade instruments from companies like Universal Robots offer precision robotic arms with force-torque sensors and SDKs for custom tooling integration, enabling rapid prototyping of assembly-line solutions.

Software & Cloud Instruments

The virtual dimension of Instrument For Making Robot is equally transformative. Tools like AWS RoboMaker provide cloud-based development environments for simulating, testing, and deploying robot applications globally. Crucially, AI development platforms serve as neural architects for robots.

Google's TensorFlow Robotics and NVIDIA JetPack SDK allow embedding complex behaviors like predictive maintenance algorithms or human gesture recognition. Meanwhile, middleware instruments like ROS bridge hardware-software communication, acting as central nervous systems coordinating sensor data and movement commands across diverse components.

Selecting Your Instrument: Key Evaluation Metrics

Choosing the optimal Instrument For Making Robot demands strategic alignment with project goals. For rapid prototyping, prioritize modularity scores – systems scored 85%+ on hardware interchangeability benchmarks often slash iteration time by 60%. Assess AI integration depth: Does the instrument support ONNX or TensorRT for optimized neural network deployment?

Review simulation fidelity using metrics like physics accuracy scores in platforms like Siemens NX. For cost-sensitive projects, calculate Total Development Cost (TDC) including subscriptions, sensor add-ons, and cloud computing fees.

Open-source instruments like Arduino reduce licensing expenses but demand greater coding expertise. Commercial alternatives like Modular Robotics offer enterprise support tiers. Crucially, analyze real-world deployment cases – healthcare projects benefit from instruments with ISO 13485 compliance, while space exploration initiatives require radiation-hardened components.

Step-by-Step: Building a Patrol Robot in 4 Weeks

Experience the power of Instrument For Making Robot firsthand by constructing an AI-powered patrol robot:

Phase 1: Instrument Setup (Day 1-3)

Select modular hardware kit (e.g., ActivePieces Explorer Edition). Assemble chassis, 360° LiDAR module, and NVidia Jetson processing unit. Install instrument software suite including Ubuntu OS, ROS Noetic, and YOLOv7 libraries.

Phase 2: Behavior Programming (Day 4-14)

Using instrument's visual programming interface, create patrol map with virtual waypoints. Implement collision avoidance using instrument's SLAM libraries. Train custom vision model to detect unauthorized access using onboard GPU – dataset preparation takes 3 days, transfer learning requires 18 hours.

Phase 3: Field Deployment (Day 15-28)

Transition instrument to development board control. Deploy weatherproof enclosure with 4G connectivity. Configure instrument's OTA (Over-the-Air) update system for remote improvements. Monitor via dashboard showing navigation efficiency metrics and anomaly detection logs.

Cross-Industry Breakthroughs: Instruments in Action

The versatility of Instrument For Making Robot sparks unconventional applications. In precision agriculture, Farmwise employs instrument systems enabling autonomous weeders to distinguish crops from invasive plants at 0.1mm accuracy. Ocean exploration startup Hydromea builds deep-sea inspection bots using pressure-tolerant instrument components rated for 6,000-meter depths.

Perhaps most fascinating is the artistic frontier: creative technologists use these tools to design kinetic installations with emergent behaviors. Witness this creativity in projects like Musical Instrument Robots: The AI-Powered Machines Redefining Music's Creative Frontier – where instrument-modified robots play acoustic instruments with human-like expressiveness.

Similarly, the engineering breakthroughs in From Circuits to Cadenzas: How AI-Powered Robots Are Shattering Music's Glass Ceiling demonstrate how instrument toolkits enable unprecedented mechatronic precision.

The Next Frontier: Self-Evolving Instruments

Future Instrument For Making Robot platforms exhibit unprecedented autonomy through three emerging capabilities. Federated learning integration will enable robot collectives to share improvement insights across instrument networks without compromising proprietary data.

Look for instruments incorporating generative design modules – imagine inputting "package delivery drone" specifications and receiving optimized CAD models and actuator configurations generated by AI. Crucially, neuromorphic computing will transform instrument responsiveness: prototypes like Intel's Loihi chips process sensor data with biological efficiency, enabling real-time adaptation to dynamic environments.

The development horizon suggests 2028 instruments might feature holographic emulation interfaces and quantum-secured OTA updates. As these tools absorb developments from adjacent fields like materials science, we'll see self-healing composites and biodegradable circuits becoming standard instrument options. This progression signifies a paradigm shift from building robots to cultivating robotic intelligences.

FAQs: Expert Insights on Instrument For Making Robot

Q: What skills do I need before using an Instrument For Making Robot?

A: Core instruments require no prior robotics experience – basic Python knowledge and electronics fundamentals suffice. Intermediate features (ROS customization) need Linux CLI proficiency, while advanced deployments (swarm coordination) demand distributed computing knowledge.

Q: Can instruments build FDA-approved medical robots?

A: Yes, platforms like da Vinci Developer Kit provide compliance-certified components but require validation protocols. Over 68% of Class II robotic medical devices use instrument-based development in early stages.

Q: How do instruments impact manufacturing costs?

A: Development costs drop 40-65% versus custom builds, though production models often migrate to specialized hardware. Real savings emerge from accelerated timelines – projects launch 3-5x faster with instruments.