Forget clunky metal submersibles! A new wave of robotics inspired by nature's softest and most resilient ocean dwellers – jellyfish, octopuses, and rays – is silently gliding into the depths. These aren't your typical rigid machines; they are Underwater Soft Robots, made from pliable polymers, gels, and smart materials designed to mimic biological motion and interact gently with delicate marine environments. Offering unparalleled advantages for navigating complex coral reefs, studying fragile organisms without disturbance, and even undertaking intricate repair tasks impossible for hard robots, Underwater Soft Robots promise to unlock ocean secrets with unprecedented grace and efficiency. Dive in to discover how this cutting-edge technology works and why it's poised to transform everything from marine biology to deep-sea engineering.

Why Hard Isn't Always Best: The Driving Force Behind Soft Robotics

The vast majority of underwater vehicles, from Remotely Operated Vehicles (ROVs) to Autonomous Underwater Vehicles (AUVs), rely on rigid metal frames and hard plastic hulls. While effective for many tasks, they face significant limitations:

Collision Risk: Navigating tight spaces like coral reefs, shipwrecks, or underwater caves poses a high risk of damage to both the environment and the expensive robot itself. A rigid arm bumping into coral can cause irreparable harm.

Limited Biocompatibility: Their presence, noise, and water displacement often scare marine life, disrupting natural behavior and hindering ecological study.

Challenge of Delicate Interaction: Tasks requiring gentle manipulation, such as collecting fragile biological samples or attaching sensors to delicate surfaces, are extremely difficult for hard grippers.

This is precisely where Underwater Soft Robots shine. By embracing flexibility rather than rigidity, they offer a fundamentally different approach.

Nature's Blueprint: Biomimicry Fuels Innovation

The core innovation behind Underwater Soft Robots lies in biomimicry – learning from and mimicking nature's solutions. Key biological inspirations include:

Octopus Arms: Capable of incredible dexterity, squeezing through tiny openings, and manipulating objects with fine motor control, thanks to muscular hydrostats (structures without rigid skeletons).

Jellyfish: Masters of efficient propulsion through rhythmic pulsations of their soft bell, minimizing turbulence.

Manta Rays: Exhibiting graceful, energy-efficient locomotion via large, flexible pectoral fins that undulate rather than rotate like propellers.

Underwater Soft Robots seek to replicate these characteristics using engineered soft materials and novel actuation methods.

The Squishy Toolbox: Materials and Mechanisms

Building robots that are inherently soft requires entirely new engineering paradigms. Here's what makes them tick:

Core Materials

Elastomers (Silicones, Ecoflex): Highly flexible, stretchable, and biocompatible materials that form the bulk of many soft robots, capable of large deformations.

Shape Memory Polymers (SMPs): Materials that can "remember" a specific shape and return to it when triggered by heat, light, or other stimuli, enabling morphing structures.

Hydrogels: Networks of hydrophilic polymers that swell with water, useful for creating structures responsive to environmental changes.

Liquid Crystal Elastomers (LCEs): Advanced materials that can undergo significant, reversible shape changes in response to heat or light, allowing for more complex motions.

Soft Actuation: Making Them Move

Instead of electric motors and gears, Underwater Soft Robots employ fascinating soft actuation techniques:

Fluidic Actuation (Pneumatics/Hydraulics): The most common method. Pressurized air or fluid (often water itself, drawn from the surrounding environment) is pumped into channels within the elastomeric structure, causing it to bend, extend, or contract – mimicking muscle action. Harvard's iconic "Octobot" is powered entirely by microfluidic logic and chemical reactions generating gas pressure.

Electroactive Polymers (EAPs): Polymers that change shape or size in response to an electric field, offering faster response times than fluidics.

Thermal/Magnetic Responsive Materials: Embedding materials that respond to heat (like SMPs or LCEs) or magnetic fields allows for untethered control. For instance, magnetic particles embedded in soft structures can be guided and actuated by external magnetic fields.

Chemical Reactions: Some prototypes generate gas bubbles internally through catalytic reactions to power movement.

How They Swim and Navigate: Beyond the Propeller

Underwater Soft Robots employ unique, bio-inspired locomotion strategies:

| Locomotion Type | Biological Inspiration | Mechanism | Advantages |

|---|---|---|---|

| Jet Propulsion (Pulsing) | Jellyfish | Contracting a soft chamber to expel water rapidly, creating thrust. Controlled inflation/deflation cycles. | Efficient at low speeds, low turbulence, good for hovering. |

| Fin Undulation/Oscillation | Rays, Cuttlefish | Creating traveling waves or oscillations along large, flexible fin surfaces. | High maneuverability, efficient cruising, silent operation. |

| Crawling/Walking | Sea Stars, Brittle Stars | Soft legs or appendages performing rhythmic contraction/extension cycles. | Ideal for traversing uneven substrates without disturbance. |

| Body Deformation | Caterpillars, Inchworms | Sequential bending or elongation/contraction of the entire soft body. | Good for confined spaces and navigating complex terrain. |

Sensing the Subtle: Integrating Perception in Soft Structures

Integrating sensors into soft bodies without compromising flexibility is a major research focus:

Embedded Strain Sensors: Conductive elastomers or liquid metal traces that change resistance when stretched, allowing the robot to sense its own shape and contact forces (vital for gentle manipulation).

Optical Fibers: Can be woven through soft structures; bends caused by deformation change light transmission characteristics.

Microfluidic Sensors: Channels containing colored fluids or chemical indicators that change based on pressure or contact, visible through transparent elastomers.

Touch Sensitivity: Developing skin-like conformable sensor arrays capable of distributed pressure sensing.

Environmental Sensors: Integrating miniaturized pH, temperature, or chemical sensors directly onto the soft body for underwater research during exploration.

Diving Into Applications: Where Squishy Robots Excel

The unique capabilities of Underwater Soft Robots unlock novel applications:

Revolutionizing Marine Biology & Ecology

Non-invasive Monitoring: Observing fragile coral reef ecosystems or shy deep-sea creatures in their natural state without inducing stress or causing damage, providing unprecedented behavioral data.

Gentle Sample Collection: Using soft grippers to collect delicate organisms, eggs, or microbial mats impossible for rigid manipulators to grasp intact.

Habitat Mapping: Navigating complex 3D reef structures and narrow crevices where traditional ROVs can't go, providing high-resolution mapping.

Underwater Infrastructure Inspection & Repair

Confined Space Access: Inspecting pipeline interiors, bridge supports, or ship hulls with complex geometries, avoiding the need for hazardous diver intervention.

Delicate Cleaning: Gently removing biofouling from sensitive structures like underwater cables or archaeological sites.

Targeted Repair: Future versions equipped with advanced manipulation could perform localized tasks like sealing small leaks or depositing material (inspired by concepts like underwater welding robots but potentially less invasive).

Search and Rescue (SAR) Support

Debris Navigation: Maneuvering through unstable wreckage after disasters where rigid robots might get stuck.

Interaction with Survivors: A soft robot could potentially interact more safely with a trapped or panicked person than a hard machine.

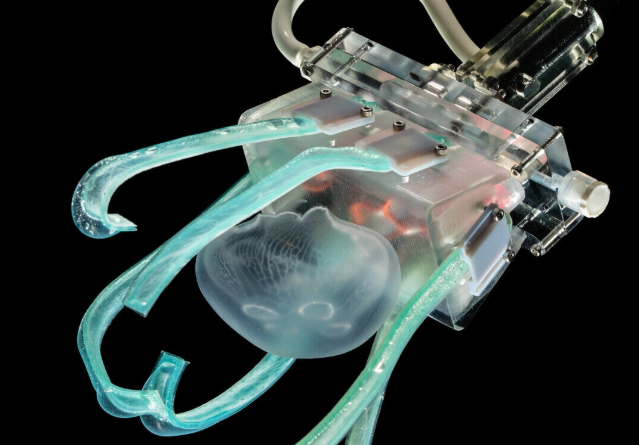

Emerging Frontiers: Biointegration & Medicine

A uniquely futuristic angle rarely explored: Underwater Soft Robots principles are finding surprising applications beyond the ocean.

Implantable Devices: Soft robotic implants that use hydraulic principles for drug delivery or tissue manipulation, leveraging biocompatible materials.

Surgical Robots: Tools capable of navigating inside the body with organ-conforming gentleness, inspired by soft robot tentacles for minimally invasive procedures.

Challenges on the Horizon: The Soft Path Forward

Despite immense promise, Underwater Soft Robots face hurdles:

Power & Endurance: Generating sufficient force, especially for deep dives, and carrying onboard power for long durations is difficult. Tethers provide power and control but limit autonomy.

Speed: Soft actuators are often slower than traditional motors, limiting speed for tasks like wide-area surveys.

Control Complexity: Accurately modeling and controlling infinitely deformable bodies in dynamic fluid environments presents significant computational challenges.

Robustness & Durability: Soft materials are vulnerable to abrasion, puncture, and biofouling. Protecting electronics and sensors within the soft body is challenging.

Mass Manufacturing: Fabricating complex soft structures reliably at scale remains difficult compared to machining metal parts.

Future Vision: Smarter, Deeper, Autonomous

Research is pushing boundaries to overcome these challenges. Key trends include:

Material Innovation: Developing self-healing polymers, tougher elastomers, and materials with embedded functional properties.

Enhanced Sensing: Integrating more sophisticated, distributed sensing directly into soft materials for proprioception and environmental feedback.

Machine Learning for Control: Employing AI to learn complex control strategies for soft bodies in turbulent environments, adapting in real-time.

Untethered Autonomy: Integrating energy harvesting (e.g., thermal, microbial fuel cells) and advanced onboard computing to create truly free-swimming soft robots for long-duration missions in challenging environments like the deep sea or other planets' oceans.

Multi-Material Printing: Advancements in 3D printing allow the creation of complex soft structures with embedded rigid components, sensors, and actuators in a single process.

The Soft Robotics Tsunami

Underwater Soft Robots represent more than just a new type of machine; they embody a paradigm shift in how we approach interaction with the complex and delicate world beneath the waves. By drawing inspiration from nature's own soft solutions and leveraging cutting-edge materials science and AI-powered control, these squishy pioneers are poised to transform ocean exploration, environmental monitoring, and undersea operations. While challenges in power, speed, and durability remain, the pace of innovation is rapid. From non-invasive study of coral reefs to potential breakthroughs in deep-sea repair and even bio-integrated medical devices, the era of soft robotics is dawning, promising a future where our machines move through water – and perhaps the human body – with the same gentle elegance as the ocean's most captivating creatures.

Frequently Asked Questions

Q1: What exactly makes an "Underwater Soft Robot" different from traditional ROVs?

A: The core distinction is material and movement. Traditional ROVs use rigid frames, joints, and hard actuators (like electric motors driving propellers or grippers). Underwater Soft Robots are constructed primarily from flexible polymers, gels, and elastomers. They move through deformation of their entire body or parts (like inflating/deflating chambers or bending limbs), mimicking biological motion (e.g., jellyfish pulsing, octopus arm bending). This offers superior maneuverability in tight spaces, gentle interaction with environments, and inherent safety near delicate structures or organisms.

Q2: How deep can current Underwater Soft Robots operate? Are they limited?

A: Depth is currently a significant challenge. Many advanced Underwater Soft Robots are prototyped and tested in labs or relatively shallow water (<100m). Deep-sea operation faces hurdles: water pressure compresses soft materials and voids (like air chambers in pneumatic actuators); protecting embedded rigid electronics is difficult; tethering limits range; power constraints hinder autonomy. Research focuses on using water-filled hydraulic systems (which don't compress), pressure-compensated designs, novel materials resistant to compression set, and developing power sources for deeper, untethered missions. They haven't yet rivaled the depth capabilities of hardened titanium ROVs.

Q3: Aren't soft robots too fragile for real underwater work?

A: Fragility is a valid concern, but resilience is actively engineered. Researchers use durable silicones and develop self-healing polymers that seal minor punctures. Robustness is addressed through design: multi-chambered pneumatics prevent catastrophic failure if one chamber leaks; incorporating tougher meshes or fibers within elastomers (like rebar in concrete) enhances strength. Some designs mimic the structure of deep-sea organisms adapted to high pressure. While they may never match the blunt-force resilience of steel ROVs, Underwater Soft Robots excel in scenarios where avoiding collisions and interaction damage is paramount, and their flexible nature inherently dissipates impact energy better than rigid structures in many cases.