The age of humanoid helpers is no longer science fiction—it's unfolding in labs, factories, and homes right now. As we navigate 2025, Robotics Android technology has reached unprecedented sophistication, blending artificial intelligence, biomechanical engineering, and contextual awareness to create machines that learn, adapt, and collaborate alongside humans. This seismic shift is redefining industries from healthcare to manufacturing, making it essential to understand which platforms lead this transformation. Below, we explore five groundbreaking Robotics Android systems setting the pace this year.

What Defines a Cutting-Edge Robotics Android in 2025?

Today's elite Robotics Android platforms share three non-negotiable traits: real-time learning autonomy, cross-environment adaptability, and intuitive human-robot collaboration. Unlike pre-programmed industrial arms, these androids leverage multimodal AI to interpret speech, gestures, and environmental cues—transforming ambiguous instructions into precise actions. Crucially, 2025's models prioritize on-device processing, minimizing cloud dependence for split-second decision-making in dynamic settings like emergency response or crowded warehouses.

The 5 Robotics Android Platforms Dominating 2025

1. Google Gemini Robotics On-Device

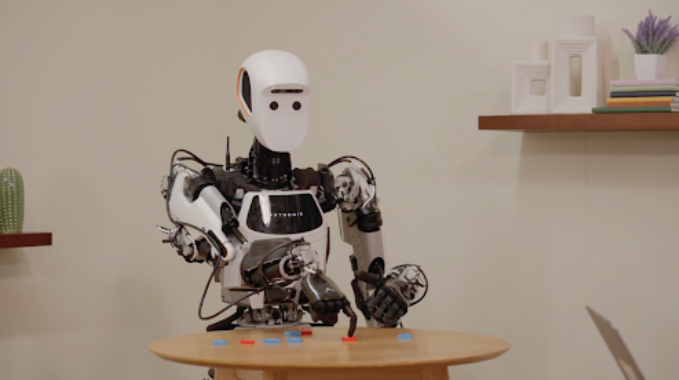

Dubbed the "Android of Robotics," Google's breakthrough system enables humanoids like Apptronik's Apollo to master complex bimanual tasks—folding clothes, assembling electronics, or unzipping bags—after just 50-100 demonstrations. Its vision-language-action (VLA) model processes sensory data locally, achieving sub-second latency for delicate operations. The SDK allows developers to simulate tasks in MuJoCo before real-world deployment, making it a favorite for agile manufacturing and domestic assistance.

Key specs: Offline AI operation ? Natural language command interpretation ? Seamless skill transfer between robot morphologies

How Robotics Androids Are Reshaping Daily Life

2. Boston Dynamics Atlas 3.0

Atlas evolves from acrobatic showman to industrial partner in 2025. Redesigned joints mimic human biomechanics, enabling 30-minute continuous operation carrying 20kg payloads. Its predictive locomotion AI anticipates terrain shifts (e.g., construction debris), while gesture recognition allows workers to direct it via hand signals in noisy environments. Currently deployed in offshore wind farms for turbine maintenance, Atlas reduces high-risk human interventions by 75%.

Key specs: Dynamic object manipulation ? Self-righting capability ? Collaborative task memory

3. Hanson Robotics Sophia-Nexus

Sophia's 2025 iteration focuses on emotional intelligence scalability. Deployed in Singaporean eldercare facilities, it analyzes vocal tone and micro-expressions to tailor cognitive therapy sessions. The android's patented "Empathy Neural Engine" learns resident preferences over time—adjusting music, reminiscence activities, or exercise regimens autonomously. Crucially, it alerts human staff to physiological distress cues (e.g., irregular pupil dilation) missed by conventional sensors.

Key specs: Real-time affect recognition ? HIPAA-compliant health monitoring ? Multilingual contextual dialogue

4. SoftBank Robotics Pepper 4

Pepper shifts from retail greeter to educational co-pilot. Integrated with MIT's RAISE platform, it guides K-12 students through personalized STEM projects using tactile, auditory, and visual cues. In pilot Barcelona schools, Pepper demonstrates chemistry experiments, then uses lidar to track students' lab work—correcting unsafe maneuvers instantly. Teachers report 40% faster concept mastery versus tablet-only instruction.

Key specs: Curriculum-aligned tutoring modules ? Multi-child engagement tracking ? Safety intervention protocols

5. Tesla Optimus Gen-2

Optimus targets affordable logistics with $25,000 mass-production targets. Its "end-to-end neural net" navigates unstructured spaces like warehouses using proprioceptive sensors instead of costly lidar. At Redwood Materials' e-waste facilities, Optimus identifies battery types via camera, safely disassembles them, and sorts components—processing 400+ units daily. The system self-calibrates tools based on material resistance feedback, slashing error rates below 0.8%.

Key specs: Tool-agnostic actuator system ? Real-time material analysis ? Swarm coordination API

Implementation Strategies for Businesses

Integrating these androids requires aligning their capabilities with operational pain points:

Start with repetitive high-injury tasks: Optimus excels at palletizing, while Atlas handles hazardous material transfers.

Prioritize data interoperability: Ensure androids integrate with existing MES/ERP systems via APIs.

Budget for skill transfer: Gemini's 50-demo training still requires 15–20 hours of supervised learning per new task.

Early adopters like Toyota report 14-month ROI through reduced injury compensation and 24/7 production continuity.

Ethical Considerations

As androids permeate sensitive roles, unresolved challenges persist:

Liability frameworks: Who bears responsibility when an AI misinterprets a command during surgery?

Emotional dependency: Sophia's eldercare success raises concerns about attachment in cognitively vulnerable patients.

Workforce displacement: MIT studies suggest retraining 34% of displaced workers for android oversight roles.

Proactive governance—not retroactive regulation—will determine whether these tools empower or endanger society.

FAQs: Robotics Android in 2025

Q: How secure are on-device AI models like Gemini against hacking?

A: Google employs hardware-enforced trusted execution environments (TEEs), isolating critical functions from network vulnerabilities. However, regular firmware updates remain essential.

Q: Can these androids operate in extreme environments?

A: Atlas functions in -30°C to 50°C ranges, while Optimus uses protective casings for corrosive settings. Desert or deep-sea operations still challenge battery and sensor systems.

Q: What's the average implementation timeline?

A: Most enterprises require 6–9 months for integration, including workflow remapping, safety certifications, and staff training.

Q: Do any models support open-source customization?

A: Gemini Robotics SDK allows extensive modification, though core safety features remain locked to prevent unintended behavior.

The 2025 Robotics Android landscape transcends gimmicks, delivering platforms with measurable productivity and safety impacts. From Google's skill-transfer revolution to Tesla's affordable automation, these systems aren't replacing humans—they're redefining what's possible when human ingenuity collaborates with machine precision. One certainty emerges: the Robotics Android evolution is accelerating faster than we dare predict.