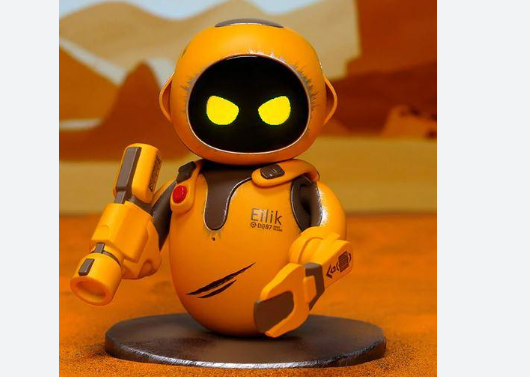

Imagine a robot small enough to perch unnoticed on the edge of your coffee mug, navigate your keyboard like a miniature explorer, or sort paperclips on your cluttered desk. Tiny Desk Robots sound like science fiction, but they are rapidly becoming a reality. Their minuscule size, seemingly defying the complexity we associate with robotics, is not magic – it's the culmination of groundbreaking advancements in material science, micro-electronics, precision engineering, and clever design. How is such miniaturization possible? Buckle up as we delve into the fascinating world of engineering that shrinks sophisticated robotics down to desk-dwelling marvels. The foundation of shrinking any technology lies in the materials used. Tiny Desk Robots rely on a new generation of substances: Ultra-lightweight, high-strength polymers replace bulky metal components. Think carbon-fiber reinforced plastics or specialized resins created via 3D micro-printing. These materials offer impressive rigidity and durability at a fraction of the weight and size of traditional options. Nanocomposites, infused with materials like graphene or carbon nanotubes, provide exceptional strength-to-weight ratios, enabling robust yet microscopic structural elements. Techniques like photochemical machining and micro-electro-discharge machining (μEDM) allow for the precise etching and shaping of incredibly thin, strong metal components—gears, levers, chassis—measured in micrometers (millionths of a meter). Shape-memory alloys (like Nitinol) are crucial, providing powerful actuation (movement) in tiny packages. Polyimide films or flexible silicone-based PCBs (Printed Circuit Boards) replace rigid fiberglass boards. This allows circuits to bend and fold, conforming to the robot's small, often intricate form factors without breaking. These substrates enable complex wiring within minuscule volumes. The miniaturization of computing and sensing technologies has been pivotal for Tiny Desk Robots. Gone are the days of needing separate chips for CPU, memory, communications, and power management. Modern SoCs integrate all these functions onto a single silicon die, often smaller than your fingernail. This drastically reduces the space needed for the robot's "brain" and control systems. Micro-Electro-Mechanical Systems (MEMS) are the unsung heroes. These are tiny devices fabricated using semiconductor processes: Micro-Sensors: Accelerometers, gyroscopes (for balance and orientation), microphones (for sound detection), pressure sensors, and even tiny cameras (often CMOS sensors) are all available as MEMS components. Micro-Actuators: Electrostatic comb drives, piezoelectric elements, and thermal actuators convert electrical signals into tiny, precise movements. These replace bulky motors and solenoids. An entire MEMS sensor or actuator can be smaller than a grain of sand. For highly specialized tasks (e.g., processing specific sensor data rapidly), custom-designed ASICs offer maximum efficiency with minimum size and power consumption compared to general-purpose microcontrollers. Bringing it all together requires engineering ingenuity focused on the micro-scale: Conventional electric motors are often too large. Alternatives dominate: Piezoelectric Actuators: Ceramic materials expand minutely when voltage is applied, creating precise linear motion. Stacked layers amplify the effect. Ideal for tiny, precise movements in arms or grippers. Shape Memory Alloys (SMAs): Wires made from alloys like Nitinol contract significantly when heated (by passing an electrical current), generating pulling force. Simple, compact, and powerful, though slower than piezo. Electrostatic & Electrothermal Actuators: Exploit forces generated by electric fields or thermal expansion at the micro-scale. Common in MEMS. Minimalism reigns. Designers use simple levers, flexures (compliant joints that bend instead of rotating on bearings), and direct-drive mechanisms to eliminate bulky gears and transmissions. Every part serves multiple functions. Fabricating components relies on: 3D Micro-Printing (μAM): Stereolithography (SLA) and Two-Photon Polymerization (2PP) allow printing complex structures layer-by-layer at resolutions down to micrometers. Lithography & Etching: Techniques borrowed from the semiconductor industry enable patterning features on silicon wafers and metals with extreme precision. Used heavily for MEMS and some structural parts. Laser Micromachining: Lasers cut, drill, and weld microscopic features with incredible accuracy. Powering a robot this small is a major challenge: Thin-film lithium-ion batteries or solid-state batteries offer high energy density in tiny packages. Often, the battery is the largest single component. Supercapacitors (Ultra-Caps) provide quick bursts of power needed for movement. Every design choice prioritizes low power. Components use nanoscale process technology (e.g., 5nm chips) consuming microwatts. Actuation methods are chosen for efficiency. Processors are optimized for task-specific workloads, spending most time in ultra-low-power sleep modes. Tasks often require short bursts of intense computation followed by long idle periods. Research explores micro-harvesting (converting ambient light, vibration, or heat into small amounts of electricity) for charging or extending operation time. Despite their size, Tiny Desk Robots often possess significant intelligence: Edge Computing allows processing data on the robot itself ("at the edge") rather than sending it to the cloud, saving energy and enabling real-time reaction. Tiny Machine Learning (TinyML) involves deploying highly optimized AI models directly onto resource-constrained microcontrollers. A TinyML model can enable gesture recognition, obstacle avoidance, or task completion using minimal power and memory. Software is hyper-optimized. Instead of a general-purpose OS, these robots run bare-metal firmware or highly stripped-down RTOS kernels. Their intelligence is focused on performing specific tasks incredibly well with limited resources. A: Absolutely! While limited by size, their tasks are often precise and niche. Examples include micro-soldering PCB components, micro-assembly of delicate parts (like watches or medical devices), targeted delivery in lab-on-a-chip systems, environmental monitoring in confined spaces, intricate inspection tasks (like inside jet engines), or simple desk tasks like organizing small items or acting as playful assistants. A: The inherent small mass makes them *less* susceptible to damage from drops than larger robots. While delicate components exist (especially protruding sensors or tools), the use of flexible materials, compliant joints, and protective design minimizes fragility. They are surprisingly robust for their size. A: Controls are essential. Some operate semi-autonomously via pre-programmed routines or AI. Many are controlled remotely using: Smartphone Apps: Via Bluetooth Low Energy (BLE). Dedicated Handheld Remotes: Similar to micro-drones. Wireless Desktop Interfaces: Offering fine control. A: Yes, advancements continue. However, fundamental physical limitations exist (power density, physics of friction at nanoscales, quantum effects). We're approaching the point where further shrinking becomes exponentially harder for fully functional robots, but sub-millimeter microbots are an active research area, often for medical applications. The existence of complex Tiny Desk Robots is a testament to human ingenuity pushing the boundaries of engineering physics. As materials become even more sophisticated, micro-electronics denser, batteries smaller and more powerful, and AI models more efficient, we can expect these diminutive marvels to become increasingly capable, affordable, and integrated into our workspaces and lives. They represent not just technological marvels, but new tools that could reshape tasks requiring precision and access in confined environments. The next time you see a **Tiny Desk Robot**, remember: its incredible miniaturization is the result of a convergence of cutting-edge technologies, meticulously designed to pack powerful functionality into a space smaller than a matchbox. It's not just small; it's science and engineering shrunk to awe-inspiring proportions.1. Material Science: Building at the Micro Scale

Advanced Polymers & Composites

Micro-Fabricated Metals & Alloys

Flexible & Stretchable Electronics Substrates

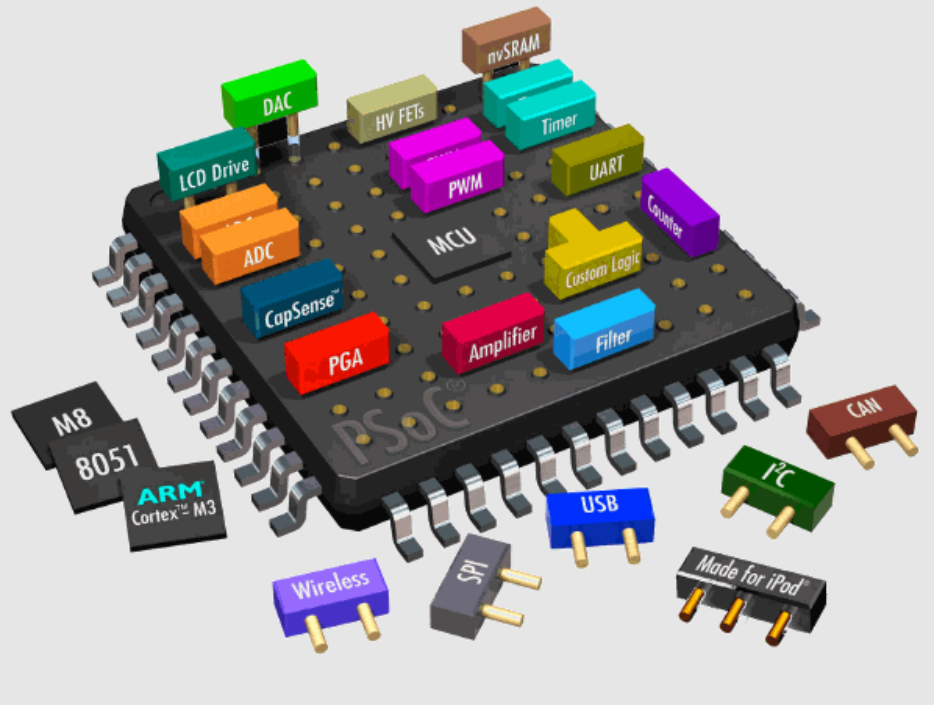

2. The Magic of Micro-Electronics: Shrinking the Brain & Senses

System-on-Chip (SoC) Dominance

MEMS: Microscopic Sensors and Actuators

Application-Specific Integrated Circuits (ASICs)

3. Precision Engineering & Revolutionary Mechanics

Novel Actuation Methods

Exploring the Types of AI Desk Robots →Kinematic Chain Optimization

Micro-Manufacturing Techniques

4. Powering the Miniature: Energy Constraints

Micro-Batteries & Ultra-Caps

Radical Energy Efficiency

Alternative Power Sources

5. Intelligent Software: Small Body, Smart Brain

Edge AI & TinyML

Focused Functionality

Frequently Asked Questions (FAQs)

The Future of Tiny Desk Robots

Q: Can such small robots actually perform useful tasks?

Q: Aren't they incredibly fragile?

Q: How do you control them?

Q: Will they get even smaller?