Imagine a robot that walks, talks, and blends seamlessly into human environments, versus one that scuttles like an insect or rolls on wheels to perform a single task with unmatched efficiency. The debate between Real-Life Humanoid Robots and Non-Humanoid Robots Examples in Real Life hinges on a core principle: form follows function. This article dives into the design tradeoffs, feasibility barriers like Zero Moment Point (ZMP) stability, and compares leading Humanoid Robot Companies like Honda and Boston Dynamics. By exploring unique case studies, we’ll uncover why the shape of a robot defines its purpose and potential.

Understanding the Design Philosophy: Form Follows Function

The idea that a robot’s form should align with its intended function is central to robotics design. Real-Life Humanoid Robots mimic human anatomy—torso, head, arms, and legs—to navigate environments built for humans, like homes or offices. In contrast, non-humanoid robots prioritize efficiency, often adopting forms inspired by nature or machinery, such as insect-like crawlers or wheeled platforms. This distinction drives their applications, strengths, and limitations.

Why Humanoids? Adaptability to Human Spaces

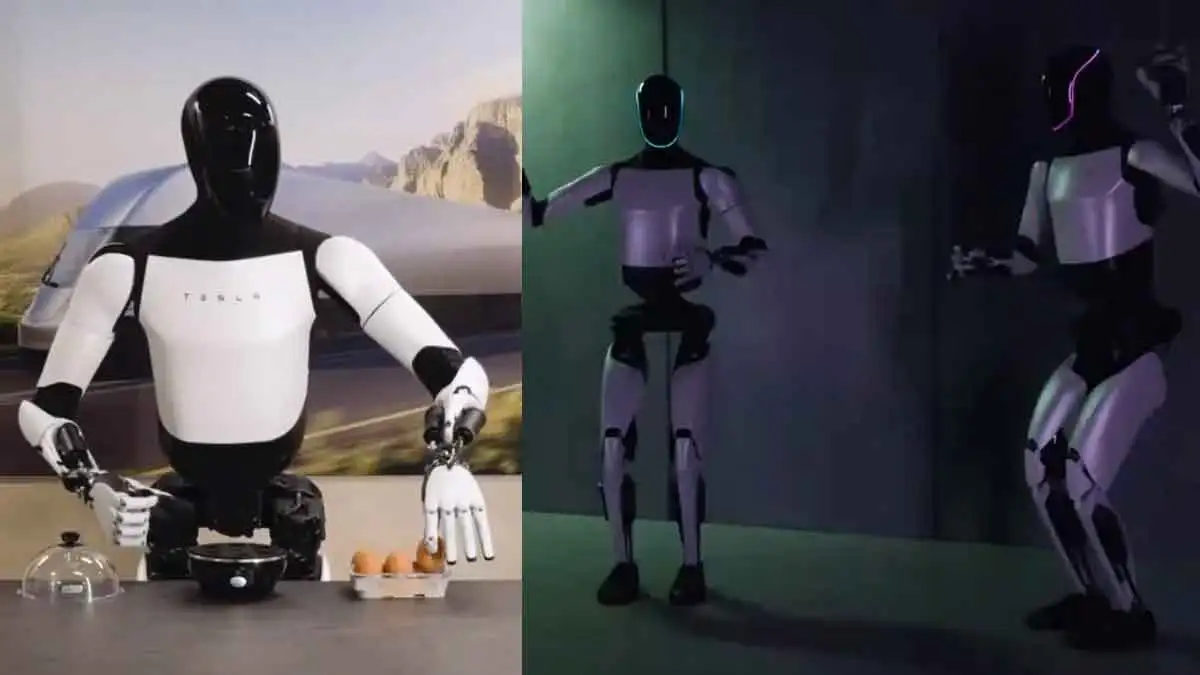

Humanoid robots are designed to thrive in human-centric environments. Their bipedal structure allows them to climb stairs, open doors, and use tools designed for humans. For instance, Honda’s ASIMO, introduced in 2000, showcased remarkable mobility, walking and climbing stairs with human-like ease. Its i-WALK technology enabled stable navigation over uneven terrain, making it a pioneer in humanoid robotics. However, this adaptability comes at a cost: complex control systems and high energy demands.

Non-Humanoid Robots: Efficiency Over Versatility

Non-Humanoid Robots Examples in Real Life include insect-inspired robots like RoBeetle, a 1-gram autonomous robot mimicking beetle locomotion. Its methanol-powered artificial muscles allow it to carry loads 2.6 times its weight, ideal for tasks like environmental monitoring in tight spaces. Similarly, Boston Dynamics’ Stretch, a wheeled warehouse robot, excels at moving heavy boxes with minimal energy. These designs sacrifice versatility for specialized efficiency, thriving in structured environments like factories.

Feasibility Barriers: Is a General-Purpose Humanoid Possible?

One burning question in robotics is: Are Humanoid Robots Possible as general-purpose machines? While humanoids like Boston Dynamics’ Atlas can perform backflips and navigate complex terrains, significant challenges remain. Let’s explore the key barriers.

ZMP Stability: The Balancing Act

Zero Moment Point (ZMP) stability is critical for bipedal robots. ZMP refers to the point on the ground where the robot’s center of gravity must align to prevent falling. Maintaining ZMP during dynamic tasks like walking or carrying heavy loads requires sophisticated sensors and real-time control systems. For example, Honda’s ASIMO uses advanced sensors to adjust its balance, but even slight disturbances, like uneven terrain, can destabilize it. Non-humanoid robots, like quadrupedal Spot by Boston Dynamics, achieve stability more easily due to their wider base of support.

Energy Efficiency and Mechanical Complexity

Humanoids require intricate joint systems and high-power actuators, increasing energy consumption. Atlas, initially hydraulic, was criticized for its energy inefficiency. The newer electric Atlas, introduced in 2024, improves efficiency but still lags behind non-humanoids like Agility Robotics’ Digit, which uses bird-inspired backward-bending knees for energy-efficient movement. Non-humanoids, with simpler designs, often outperform humanoids in repetitive tasks, such as warehouse logistics.

Learn About Autonomous Biohybrids

Case Studies: Warehouse Bots vs. Receptionist Humanoids

Comparing real-world applications highlights the strengths of each robot type.

Warehouse Bots: Non-Humanoid Efficiency

In warehouses, non-humanoid robots like Digit and Stretch dominate. Digit’s bipedal yet non-humanoid design allows it to navigate cluttered spaces and carry packages, with backward-bending knees optimizing energy use. Stretch, with its wheeled base, moves heavy loads quickly, reducing human labor in repetitive tasks. These robots excel in structured environments where speed and reliability are paramount.

Receptionist Humanoids: Social Interaction

Real-Life Humanoid Robots like SoftBank’s Pepper shine in social settings. Pepper, with its expressive face and natural language processing, serves as a receptionist in hotels and offices, engaging users through speech and emotion recognition. Its human-like form fosters trust and familiarity, making it ideal for customer-facing roles. However, its limited mobility and high cost restrict its scalability compared to non-humanoids.

Humanoid Robot Company Comparison: Honda vs. Boston Dynamics

Leading Humanoid Robot Companies like Honda and Boston Dynamics illustrate different approaches to robotics.

Honda: Pioneering Humanoid Mobility

Honda’s ASIMO set the standard for humanoid robots with its advanced bipedal locomotion. Priced at over $1 million, ASIMO was a research marvel but too costly for commercial use. Honda’s focus on human-like kinematics made ASIMO ideal for studying motor learning, but its high cost and energy demands limited its practical applications.

Boston Dynamics: Hybrid Innovation

Boston Dynamics takes a hybrid approach, blending humanoid and non-humanoid designs. Atlas, a bipedal humanoid, showcases agility with backflips and parkour, while Spot and Stretch prioritize non-humanoid efficiency. In 2024, Boston Dynamics partnered with Hyundai to deploy Atlas in automotive manufacturing, proving its real-world potential. Their ability to balance research and commercial applications sets them apart.

Unique Perspective: Bio-Inspired Design as a Bridge

A novel angle in robotics is bio-inspired design, blending humanoid and non-humanoid principles. For instance, integrating insect-like resilience (like RoBeetle’s artificial muscles) into humanoid frames could enhance durability without sacrificing adaptability. Similarly, humanoids could adopt non-humanoid energy-saving mechanisms, like Digit’s bird-inspired legs, to overcome efficiency barriers. This hybrid approach could redefine the future of robotics, creating versatile machines that balance form and function.

FAQs

What Are the Main Differences Between Humanoid and Non-Humanoid Robots?

Humanoid robots mimic human anatomy for adaptability in human environments, while non-humanoid robots prioritize efficiency with specialized forms, like wheels or insect-like legs, for specific tasks.

Are Humanoid Robots Possible for Everyday Use?

Yes, but challenges like ZMP stability, energy efficiency, and high costs remain. Robots like Pepper are used as receptionists, but general-purpose humanoids are still in development.

Which Humanoid Robot Company Leads the Industry?

Boston Dynamics leads with its versatile Atlas and non-humanoid robots like Spot, while Honda’s ASIMO pioneered humanoid mobility. The best depends on the application.

Can Non-Humanoid Robots Examples in Real Life Outperform Humanoids?

In specific tasks like warehouse logistics, non-humanoids like Stretch outperform humanoids due to their energy efficiency and simpler designs, but they lack versatility in human-centric environments.

Conclusion

The choice between Real-Life Humanoid Robots and non-humanoid robots boils down to purpose: humanoids excel in adaptability and social interaction, while non-humanoids dominate in efficiency and specialized tasks. Feasibility barriers like ZMP stability and energy demands continue to challenge humanoids, but innovations in bio-inspired design offer a promising future. By understanding these tradeoffs and comparing Humanoid Robot Companies like Honda and Boston Dynamics, we see that form truly follows function in shaping the robotics landscape.