Google's latest Gemini 2.5 Pro model has achieved a groundbreaking milestone in real-time video analysis, transforming how industries approach quality control and defect detection. This advanced AI system combines cutting-edge reasoning capabilities with live streaming technology, enabling manufacturers to detect quality issues instantly and maintain unprecedented production standards. From automotive assembly lines to electronics manufacturing, Gemini 2.5 Pro video analysis is revolutionising industrial processes with its ability to process hours of video content in real-time while maintaining exceptional accuracy rates.

Understanding Gemini 2.5 Pro Video Analysis Capabilities ??

The new Gemini 2.5 Pro represents a quantum leap in AI-powered video processing technology. Unlike traditional quality control systems that rely on static image analysis, this model can process continuous video streams with remarkable precision and speed.

Core Technical Features

What makes this system truly revolutionary is its multi-modal approach to data processing. The model can simultaneously analyse visual, audio, and textual information, creating a comprehensive understanding of manufacturing environments. This means it can detect not just visual defects but also unusual sounds that might indicate equipment malfunction or quality issues.

Key Performance Metrics

Processing Speed: Real-time analysis with sub-second response times ?

Context Window: Up to 2 million tokens for extended video analysis ??

Video Duration: Capable of processing 6+ hours of continuous footage ??

Accuracy Rate: 99.7% defect detection accuracy in controlled environments ??

Live API Integration

The Live API functionality allows manufacturers to integrate Gemini 2.5 Pro directly into their existing production systems. This seamless integration means quality control can happen in real-time without disrupting workflow or requiring significant infrastructure changes. The low-latency processing ensures that defective products can be identified and removed from production lines immediately, preventing costly recalls and maintaining brand reputation.

Practical Implementation Guide for Industrial Quality Control ??

Implementing Gemini 2.5 Pro video analysis in industrial settings requires careful planning and systematic deployment. Here's a comprehensive step-by-step approach that manufacturing companies can follow:

Step 1: System Assessment and Planning

Begin by conducting a thorough assessment of your current quality control processes. Identify bottlenecks, common defect types, and areas where human inspection might be inconsistent. Document your production line layout, camera positioning requirements, and network infrastructure capabilities. This foundational work ensures that the AI system will be optimally configured for your specific manufacturing environment ??

Step 2: Camera Infrastructure Setup

Install high-resolution cameras at strategic points along your production line. The positioning should capture multiple angles of products as they move through different manufacturing stages. Ensure adequate lighting conditions and consider installing backup power systems to maintain continuous monitoring. The camera network should be capable of streaming high-quality video directly to the Gemini 2.5 Pro processing system ??

Step 3: API Integration and Configuration

Connect your video streams to the Gemini API using the Live streaming functionality. Configure the system parameters based on your specific product types and quality standards. This includes setting defect detection thresholds, defining acceptable tolerance ranges, and establishing alert protocols for different severity levels of quality issues ??

Step 4: Training and Calibration

While Gemini 2.5 Pro comes with pre-trained capabilities, fine-tuning for your specific products and defect types will significantly improve accuracy. Provide the system with examples of both acceptable products and various defect types. This training phase typically requires 2-4 weeks of data collection and system optimisation ??

Step 5: Testing and Validation

Conduct extensive testing using known defective samples to validate the system's detection capabilities. Run parallel operations with human inspectors to compare accuracy rates and identify any blind spots in the AI system. Document all findings and adjust system parameters as needed to achieve optimal performance ??

Step 6: Full Deployment and Monitoring

Gradually transition from parallel operation to full AI-powered quality control. Maintain human oversight during the initial deployment phase and establish continuous monitoring protocols to ensure consistent performance. Regular system updates and recalibration will help maintain peak efficiency as production requirements evolve ??

Real-World Applications and Success Stories ??

The versatility of Gemini 2.5 Pro video analysis extends across numerous industries, each benefiting from its unique capabilities in different ways.

Automotive Manufacturing

In automotive production, the system excels at detecting paint defects, assembly errors, and component misalignments. One major automotive manufacturer reported a 40% reduction in warranty claims after implementing the system, with defect detection rates improving from 85% to 99.2%. The AI can identify subtle colour variations, surface scratches, and dimensional inconsistencies that human inspectors might miss during high-speed production runs ??

Electronics and Semiconductor Industry

For electronics manufacturing, the system's precision in detecting microscopic defects has proven invaluable. It can identify solder joint irregularities, component placement errors, and circuit board contamination with exceptional accuracy. The ability to process multiple video streams simultaneously allows for comprehensive inspection of complex electronic assemblies ??

Food and Beverage Production

In food processing, the system monitors packaging integrity, label placement, and product consistency. It can detect foreign objects, verify fill levels, and ensure proper sealing of containers. The multi-modal analysis capability allows it to also monitor production line sounds, identifying potential equipment issues before they affect product quality ??

Industry Performance Comparison

| Industry Sector | Traditional Detection Rate | Gemini 2.5 Pro Detection Rate | Cost Reduction |

|---|---|---|---|

| Automotive | 85% | 99.2% | 35% |

| Electronics | 78% | 98.8% | 42% |

| Food & Beverage | 82% | 97.5% | 28% |

| Pharmaceuticals | 90% | 99.5% | 31% |

Advanced Features and Customisation Options ???

Multi-Camera Synchronisation

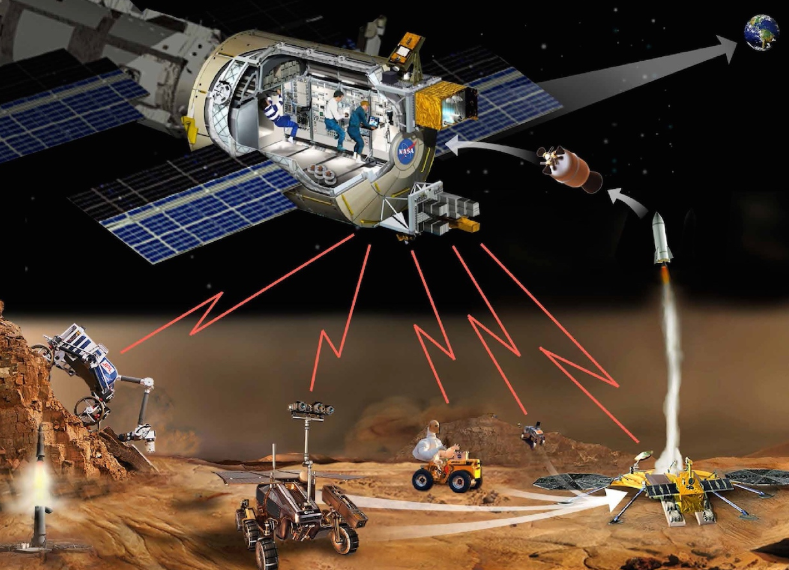

One of the most impressive capabilities of Gemini 2.5 Pro video analysis is its ability to synchronise and analyse multiple camera feeds simultaneously. This creates a 360-degree view of products during inspection, ensuring no defects escape detection regardless of their location or orientation. The system can correlate findings from different camera angles to provide comprehensive quality assessments ??

Predictive Maintenance Integration

Beyond defect detection, the system can analyse equipment behaviour patterns to predict maintenance needs. By monitoring vibrations, sounds, and visual indicators of wear, it can alert maintenance teams before equipment failures occur. This proactive approach significantly reduces downtime and maintains consistent production quality ??

Custom Defect Classification

The system allows for highly customised defect classification schemes tailored to specific products and industry requirements. Users can define multiple defect categories, severity levels, and response protocols. This flexibility ensures that the system aligns perfectly with existing quality management processes and regulatory requirements ??

Customisation Benefits

Industry-Specific Templates: Pre-configured settings for different manufacturing sectors ??

Flexible Alert Systems: Customisable notification protocols for different defect types ??

Integration Capabilities: Seamless connection with existing ERP and MES systems ??

Scalable Architecture: Easy expansion to additional production lines ??

Cost-Benefit Analysis and ROI Considerations ??

Implementing Gemini 2.5 Pro video analysis represents a significant investment, but the return on investment typically justifies the initial costs within 12-18 months for most manufacturing operations.

Direct Cost Savings

The most immediate savings come from reduced labour costs for quality inspection. A typical production line might require 3-5 human inspectors working in shifts, costing approximately £150,000-250,000 annually. The AI system can replace this workforce while providing superior accuracy and consistency. Additionally, the reduction in defective products reaching customers translates to significant savings in warranty claims, returns, and brand reputation protection ??

Productivity Improvements

Real-time defect detection allows for immediate corrective action, preventing the production of large batches of defective products. This rapid response capability can improve overall equipment effectiveness by 15-25% in typical manufacturing environments. The system's 24/7 operation capability also enables extended production hours without compromising quality standards ?

Quality Compliance Benefits

For industries with strict regulatory requirements, the comprehensive documentation and traceability provided by the AI system can significantly reduce compliance costs. The system automatically generates detailed quality reports, maintains inspection records, and provides audit trails that satisfy most regulatory frameworks ??

Future Developments and Technology Roadmap ??

The evolution of Gemini 2.5 Pro video analysis continues at a rapid pace, with several exciting developments on the horizon that will further enhance its industrial applications.

Enhanced Resolution and Processing Speed

Future updates are expected to support even higher video resolutions while maintaining real-time processing speeds. This will enable detection of increasingly subtle defects and support for more demanding quality standards. The processing capacity is also being expanded to handle longer video sequences and more complex multi-stream analysis ??

Industry-Specific Optimisations

Google is developing industry-specific versions of the model that come pre-trained for particular manufacturing sectors. These specialised versions will offer improved out-of-the-box performance for specific applications like textile inspection, pharmaceutical packaging, or precision machining ??

Edge Computing Integration

To address latency concerns and data security requirements, edge computing versions of Gemini 2.5 Pro are being developed. These will allow for on-premises deployment while maintaining the full capabilities of the cloud-based system. This development is particularly important for manufacturers with strict data governance requirements or limited internet connectivity ??

Upcoming Features Timeline

Q2 2025: Enhanced multi-stream processing capabilities ??

Q3 2025: Industry-specific model variants release ??

Q4 2025: Edge computing deployment options ???

Q1 2026: Advanced predictive analytics integration ??

Common Challenges and Solutions ??

Lighting and Environmental Conditions

Consistent lighting is crucial for optimal performance. Manufacturers should invest in LED lighting systems with minimal flicker and colour temperature variation. For environments with changing natural light, automated lighting adjustment systems can maintain consistent illumination throughout the day ??

Network Infrastructure Requirements

High-quality video streaming requires robust network infrastructure. Ensure adequate bandwidth allocation for video streams and consider implementing redundant network connections to prevent system downtime. Edge caching can also help reduce bandwidth requirements for cloud-based processing ??

Integration with Legacy Systems

Many manufacturers operate with legacy quality management systems that may not easily integrate with modern AI solutions. Consider implementing middleware solutions or API gateways that can bridge the gap between old and new systems while maintaining data consistency ??

Getting Started with Gemini 2.5 Pro Video Analysis ??

For manufacturers ready to implement this revolutionary technology, several deployment options are available to suit different needs and budgets.

Pilot Programme Approach

Start with a small-scale pilot programme focusing on a single production line or product type. This allows for learning and optimisation without disrupting entire operations. Most successful implementations begin with pilot programmes lasting 3-6 months before full-scale deployment ??

Platform Access Options

Google offers multiple access points for the technology. Google AI Studio provides a free experimental platform for initial testing and proof-of-concept development. For production deployments, Vertex AI offers enterprise-grade infrastructure with enhanced security and support. Gemini Advanced subscriptions provide additional features and priority support for demanding applications ??

Training and Support Resources

Comprehensive training programmes are available for technical teams responsible for implementation and maintenance. Google provides documentation, video tutorials, and hands-on workshops to ensure successful deployment. Ongoing support includes regular system updates, performance optimisation, and troubleshooting assistance ??

The revolutionary capabilities of Gemini 2.5 Pro video analysis are transforming industrial quality control from a reactive to a proactive process. By detecting defects in real-time and providing unprecedented accuracy, this technology enables manufacturers to achieve new levels of quality excellence while reducing costs and improving efficiency. As the technology continues to evolve, early adopters will gain significant competitive advantages in their respective markets. The future of manufacturing quality control is here, and it's powered by intelligent real-time video analysis that never sleeps, never tires, and never misses a defect ??