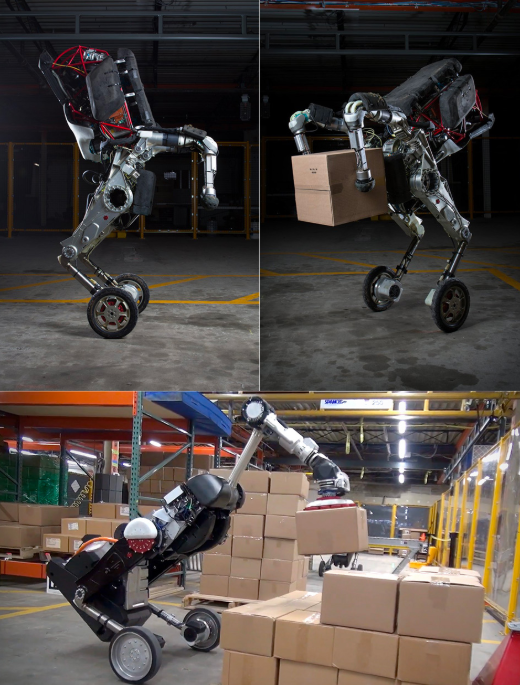

Looking to revolutionize your warehouse operations? Amazon's AI-powered warehouse robots, especially the game-changing Handle 2.0 Inventory AI, are reshaping how businesses handle inventory, boost efficiency, and cut costs. In this no-fluff guide, we'll break down how these robots work, why they're a must-have, and actionable tips to master them. Spoiler: Your warehouse's future just got smarter! ??

What Are Amazon AI Warehouse Management Robots?

Amazon's AI-driven robots, like Handle 2.0, combine cutting-edge technologies—computer vision, machine learning, and sensor fusion—to automate inventory tasks. Unlike traditional systems, these robots learn from their environment, adapt to cluttered spaces, and handle fragile items with surgical precision. Think of them as the "brainy hands" of your warehouse!

Core Tech Behind Handle 2.0 Inventory AI

AI-Powered Vision: Cameras and sensors scan shelves in real-time, identifying items and calculating optimal pickup paths.

Tactile Feedback: Advanced force sensors prevent damage by adjusting grip strength (no more crushed boxes!).

Predictive Analytics: Machine learning forecasts demand, ensuring high-turnover items are always front-row ready.

Step-by-Step: How to Deploy Handle 2.0 in Your Warehouse

1. Setup & Calibration

Hardware Check: Install charging stations and navigation beacons. Ensure floor markings are clear for robot paths.

Software Integration: Sync with existing WMS (Warehouse Management System) via Amazon's API.

2. Training the AI

Item Database: Upload product specs (size, weight, fragility) to the robot's database.

Simulation Testing: Use Amazon's Real2Sim tool to model scenarios and refine handling logic.

3. Navigation & Task Allocation

Dynamic Routing: Robots automatically avoid obstacles and reroute during peak hours.

Task Prioritization: Assign high-priority orders first (e.g., same-day delivery items).

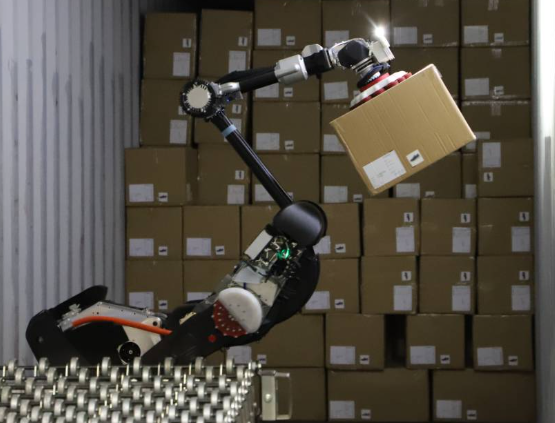

4. Precision Picking & Packing

Grip Adjustments: For delicate items like ceramics, the robot switches to "gentle mode" using suction cups.

Error Handling: If an item slips, the robot retries or flags it for human review.

5. Maintenance & Upgrades

Daily Checks: Clean sensors and recalibrate grippers.

Firmware Updates: Install monthly AI patches for bug fixes and performance boosts.

Real-World Results: Why Amazon's Robots Rock

25% Faster Order Fulfillment: Robots reduce walking time by mapping the quickest routes.

75% Inventory Accuracy: AI minimizes human errors in stock counts.

Cost Savings: 30% lower labor costs for repetitive tasks (source: Amazon's 2025 Logistics Report).

Case Study: A mid-sized fashion retailer cut delivery times from 48h to 12h using Handle 2.0's predictive stocking system.

Pros & Cons of Handle 2.0 Inventory AI

| Pros | Cons |

|---|---|

| ? 24/7 Operation | ? High upfront costs (~$250k/robot) |

| ? Reduced Workplace Injuries | ? Limited to structured environments |

| ? Scalable for Seasonal Demand | ? Complex setup for irregular layouts |

5 Common Questions Answered

Q1: Can Handle 2.0 work with existing shelves?

Yes! It adapts to both standardized pallets and irregular storage units (like fabric-covered bins).

Q2: How does it handle fragile items?

The robot uses suction cups and pressure sensors to apply gentle force, ideal for glassware or electronics.

Q3: What's the learning curve?

Most teams master basic operations in 1-2 weeks with Amazon's training modules.

Q4: Can it integrate with third-party software?

Absolutely! REST APIs allow connectivity with ERP and inventory tools like TradeGecko.

Q5: Is data security a risk?

Amazon uses end-to-end encryption, and you can enable private cloud deployments.

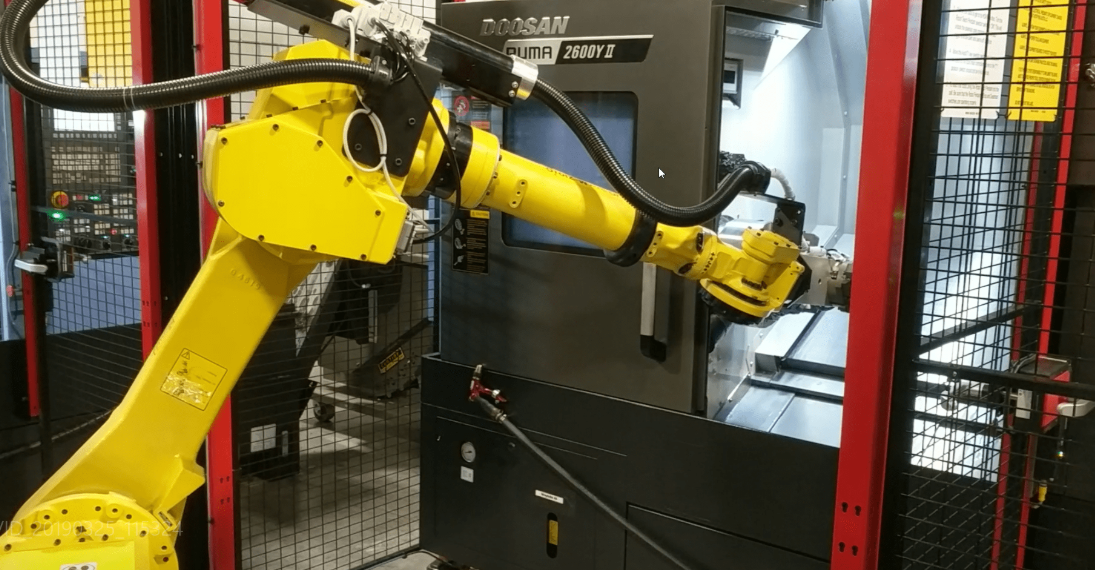

The Future of Warehouse AI: What's Next?

Amazon's testing Digit, a bipedal robot for stairs and uneven terrain, and Sequoia, a vision-driven sorting system. Rumor has it, they're working on drones for aerial inventory scans!