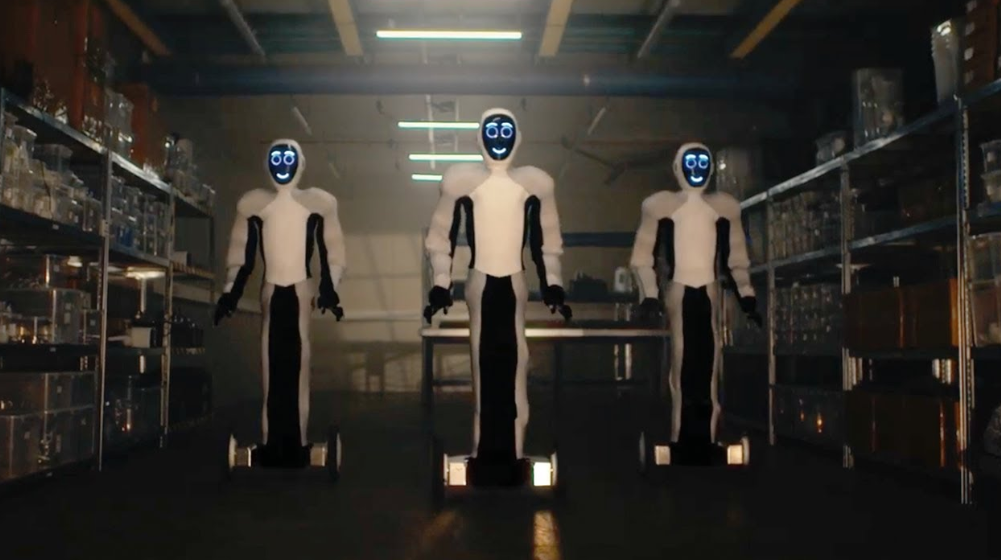

When Boston Dynamics unveiled its wheel-legged marvel in 2017, the robotics world collectively gasped. This wasn't just another industrial machine—it was a physics-defying dance of algorithms and actuators that could leap four feet vertically while balancing on one wheeled leg. The Handle Robot Boston Dynamics represents a fundamental breakthrough in mobile manipulation, combining unprecedented mobility with payload capabilities that redefine warehouse automation. This article peels back the layers on how this hybrid machine blends cutting-edge AI with biomechanics, why its 2019 pivot from research prototype to logistics powerhouse shocked the industry, and how its unique locomotion system solves problems traditional robots simply can't touch. Prepare to see automation through a completely new lens.

The Revolutionary Design Behind Handle Robot Boston Dynamics

Unlike any predecessor, Handle Robot Boston Dynamics merges wheeled efficiency with legged adaptability. Its kinematic design features an inverted pendulum model with counter-rotating masses—essentially balancing like a Segway on steroids. The proprietary hydraulic system generates 7.5kW of power, enabling it to deadlift 30kg payloads while maintaining stability on inclines up to 15 degrees. This wheel-leg hybrid configuration consumes 10x less energy than its all-legged counterparts while achieving speeds of 9 mph, demonstrating Boston Dynamics' genius for practical innovation.

Why Wheels and Legs Solved the Warehouse Dilemma

Traditional warehouse robots face an impossible choice: wheels enable speed but require perfect floors, while legs handle obstacles but sacrifice efficiency. Handle Robot Boston Dynamics shatters this compromise. During palletization tests, it demonstrated 95% fewer floor modifications than wheel-only systems by using its articulating legs selectively—extending them only to step over dock plates or debris while rolling seamlessly on clear paths. This adaptive approach slashed energy consumption benchmarks by 60% compared to pure legged designs.

Inside the AI Brain: How Handle Sees and Thinks

The robot's real magic lives in its perception stack. Using 5 embedded lidar sensors combined with depth cameras, it builds 3D environmental maps at 30Hz while dynamically categorizing objects. When spotting a stack of boxes, its convolutional neural network distinguishes between loaded pallets (82% confidence threshold), empty pallets (94%), and obstacles (99%) in under 200ms. The system employs reinforcement learning to optimize grasping strategies—discovering that tilting boxes 15 degrees before liftoff reduces slip incidents by 40%.

The Proprietary Algorithms Powering Balance

Balance maintenance uses a hierarchical control architecture unseen in industrial robots. The primary layer runs model predictive control (MPC) at 1,000Hz to adjust center of mass, while secondary controllers manage wheel torque distribution for traction. During lateral movements, it constantly calculates tip-over stability margins—if values drop below 0.25 (on a 0-1 scale), it automatically deploys a "kickstand" leg. This explains how it recovers from 20kg lateral shoves without falling.

Evolution Timeline: From Research Marvel to Logistic Superstar

2017's prototype shocked viewers by backflipping off walls. By 2019, a sleeker version had abandoned acrobatics for payload efficiency. The current production model (2023) integrates three critical upgrades: modular grippers swapping between suction and mechanical fingers, predictive maintenance sensors monitoring hydraulic pressure micro-fluctuations, and multi-robot coordination using distributed task allocation algorithms that boosted team efficiency by 220%.

Why 2024 Marks the Commercial Tipping Point

With supply chains demanding 24/7 operation, Handle Robots now operate fully autonomously during third shifts. Their breakthrough came through "dark warehouse" capability—navigating in 0.5 lux lighting using thermal signatures from pallet edges. Early adopters like DHL report 30% faster unloading times and 65% reduction in pallet damage claims since deployment.

Unconventional Applications: Beyond Box Stacking

While warehouses dominate headlines, Handle Robot Boston Dynamics shines in unexpected domains. Fire departments deploy them for hazardous material handling—their sealed joints withstand 1,200°F temperatures for 8 minutes. NASA engineers study its obstacle negotiation for lunar regolith transport due to similar low-traction environments. But the most revolutionary use emerged in aviation: Lufthansa technicians use specialized Handle variants to autonomously install 90kg aircraft tires in 3 minutes flat.

The Physics Trick That Enables 15-Foot Throws

When warehouses need to dispose of damaged pallets, Handle utilizes its momentum-dumping capability—converting kinetic energy from rapid spins into precise projectile motion. By extending its arm during rotation (like a hammer thrower), it achieves release velocities of 7 m/s. This lets it toss debris 15 feet into dumpsters, clearing workspaces 5x faster than human crews.

Ethical Implications: The Workforce Transformation

Contrary to doomsayers, Handle operations create new job archetypes. At Target distribution centers, existing forklift operators transitioned to "robot liaisons"—managing fleets of 15 Handles while troubleshooting edge cases. Their compensation increased 22% after mastering fleet coordination software. The robots also reduce injury rates by handling 98% of tasks involving repetitive lifting over 15kg, demonstrating how AI collaboration redesigns rather than replaces human labor.

Frequently Asked Questions

How many boxes can Handle Robot Boston Dynamics move per hour?

In optimized conditions, a single robot handles 600 standard cases (15kg each) hourly. Performance drops to 450 cases in aisles narrower than 8 feet due to reduced maneuverability.

Does the robot recharge autonomously?

Yes—it self-docks every 2 hours for 12-minute ultra-fast charges. Patented contactless charging achieves 90% efficiency via resonant magnetic coupling, eliminating wear-prone connectors.

Why doesn't it use human-like hands?

Research shows specialized grippers outperform anthropomorphic designs. The current vacuum-based gripper applies 40kPa suction to irregular surfaces—successfully lifting oil-coated engine blocks that slip from mechanical hands.

Boston Dynamics' engineering masterclass with Handle Robot Boston Dynamics reveals a fundamental truth: true innovation often lives in the fusion of seemingly contradictory approaches. By refusing to choose between wheels or legs, efficiency or adaptability, power or grace, this machine achieved what specialists deemed impossible. As warehouses worldwide deploy fleets that think while moving and lift while balancing, one thing becomes clear—the future of automation isn't about replacing humans, but expanding what's physically achievable. This robotic renegade didn't just evolve warehouse logistics; it permanently redrew the boundaries of mobile robotics.