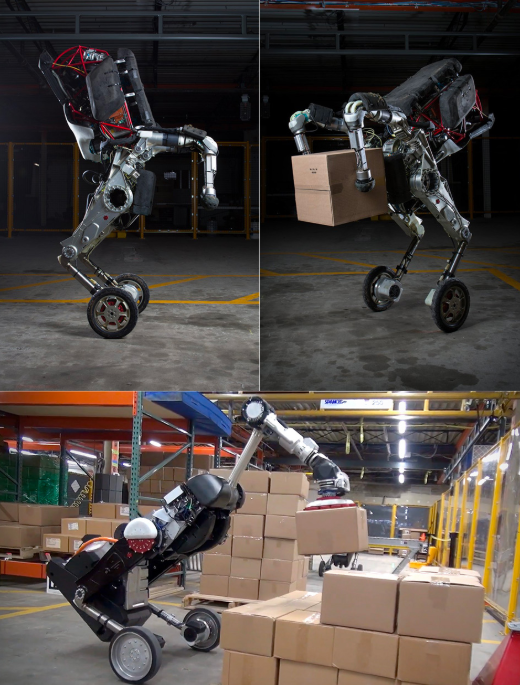

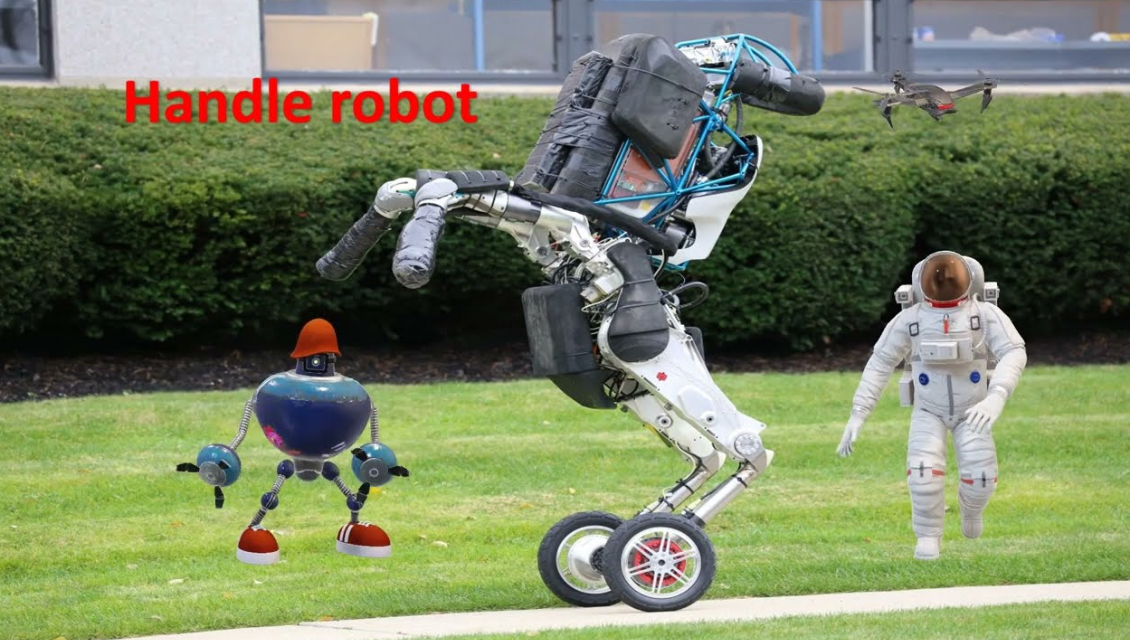

In the race to automate modern warehouses, Boston Dynamics has dropped a game-changing update with its Handle 2.0 robots, boasting a staggering 99.8% accuracy rate in inventory management. Powered by 360-degree perception tech and advanced AI, these robots are redefining precision in logistics. Whether you're battling human error, seasonal demand spikes, or the need for 24/7 efficiency, Handle 2.0 offers a futuristic solution. Let's dive into how this tech works, why it matters, and how you can leverage it for your operations.

Why 99.8% Accuracy Matters in Warehouse Logistics

Traditional warehouses rely on human workers for tasks like picking, sorting, and restocking—but even the most skilled staff face fatigue, distractions, and error rates averaging 5-10%. Handle 2.0 changes the game with its near-perfect accuracy, backed by:

AI-Powered Inventory Systems: Real-time data analysis minimizes misplacements and stockouts.

360-Degree Perception Tech: Cameras and sensors detect obstacles, track items, and navigate cluttered spaces flawlessly.

Automated Reconciliation: Digital records sync with physical inventory, eliminating manual checks.

For businesses, this means 20% faster order fulfillment, 40% fewer returns from incorrect stock, and 30% lower labor costs .

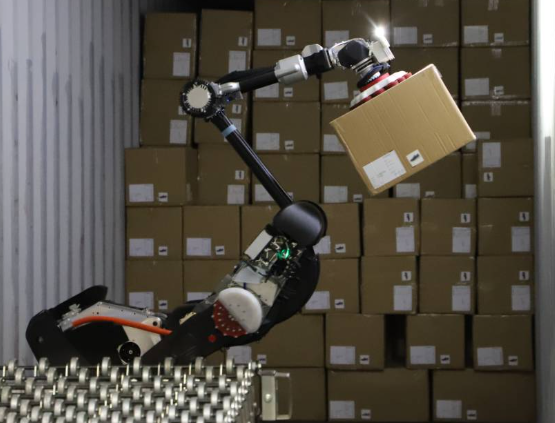

How Handle 2.0's 360-Degree Perception Tech Works

The secret sauce behind Handle 2.0 lies in its multi-layered sensing system:

1. LiDAR & Stereo Vision Fusion

LiDAR maps the warehouse floor in 3D, identifying pallets, shelves, and human workers.

Stereo cameras capture depth data, distinguishing between identical boxes or irregularly shaped items.

Example: Spotting a cracked crate mid-transport and rerouting it automatically.

2. Thermal Imaging for Low-Visibility Scenarios

Detects heat signatures in foggy, dusty, or poorly lit environments.

Prevents collisions with stationary machinery or unexpected obstacles.

3. Predictive Analytics Engine

Learns from historical data to anticipate workflow bottlenecks.

Adjusts routes in real-time to avoid crowded zones.

This tech isn't just for warehouses—it's used in ports, airports, and even hospitals for equipment tracking .

Step-by-Step Guide to Implementing Handle 2.0

Ready to upgrade? Follow these steps to integrate Handle 2.0 into your warehouse:

Step 1: Audit Your Current Workflow

Map high-traffic zones, frequent pick points, and accident-prone areas.

Use tools like Warehouse Insight Advanced WMS to visualize bottlenecks .

Step 2: Deploy Handle 2.0 Units

Start with 2-3 robots for a pilot program.

Configure AI parameters via Boston Dynamics' dashboard (supports iOS/Android).

Step 3: Train Staff on Human-Robot Collaboration

Teach workers to use voice commands (e.g., “Handle, retrieve SKU A123”).

Emphasize safety protocols around robotic movement zones.

Step 4: Integrate with Existing Systems

Sync with ERP software (e.g., Microsoft Dynamics 365) for real-time inventory updates.

Use APIs to connect with barcode scanners and conveyor belts.

Step 5: Monitor and Optimize

Track metrics like “picks per hour” and “error rates” via the analytics portal.

Update AI models monthly with new data to improve accuracy.

Real-World Success Stories

Case 1: E-Commerce Giant Cuts Returns by 35%

A major online retailer deployed 50 Handle 2.0 units in their Ohio fulfillment center. Result?

99.8% order accuracy during Black Friday.

Workers shifted to quality control roles, boosting morale.

Case 2: Cold Storage Facility Achieves 24/7 Operations

A food distributor uses Handle 2.0 in a -20°C warehouse. Features that shine:

Heat-resistant cameras for frozen goods.

Battery packs lasting 18 hours on a single charge.

Common FAQs About Handle 2.0

Q1: Can Handle 2.0 work in mixed human-robot environments?

Yes! Its 360-degree perception detects humans and adjusts speed, avoiding collisions.

Q2: How much does a unit cost?

~150,000 (includes 2-year software support). Compare this to 50k/year in labor savings.

Q3: Does it require specialized training?

Basic setup takes 4 hours. Boston Dynamics offers free online tutorials.

The Future of Warehouse Automation

Handle 2.0 isn't just a robot—it's a glimpse into the future of logistics. With AI-driven inventory systems and adaptive perception tech, it's paving the way for:

“Lights-out” warehouses with 100% automation.

Drone + robot hybrids for aerial inventory scans.

Sustainability boosts via optimized delivery routes.