BMW's latest breakthrough in automotive manufacturing—multimodal inspection robots—has set a new industry standard with 99.6% defect detection accuracy, reshaping how luxury vehicles are built. This milestone isn't just about cutting-edge tech; it's a game-changer for quality assurance, blending AI, robotics, and data analytics to deliver perfection. Let's dive into how BMW pulled this off and why it matters for drivers and manufacturers alike.

The Evolution of BMW's Quality Control

BMW has always been synonymous with precision, but the introduction of multimodal inspection robots marks a quantum leap. These robots combine computer vision, tactile sensing, and AI-driven analytics to inspect every millimeter of a vehicle. Traditional methods relied on human eyes and mechanical checks, but this new system operates 24/7, eliminating fatigue-induced errors and slashing detection time by 40% .

For example, BMW's geometric optical measurement (GOM) system scans entire vehicles in minutes, capturing micron-level details that older touch-based methods missed . Coupled with AI algorithms, these robots now predict potential flaws before they even materialize, thanks to predictive maintenance models .

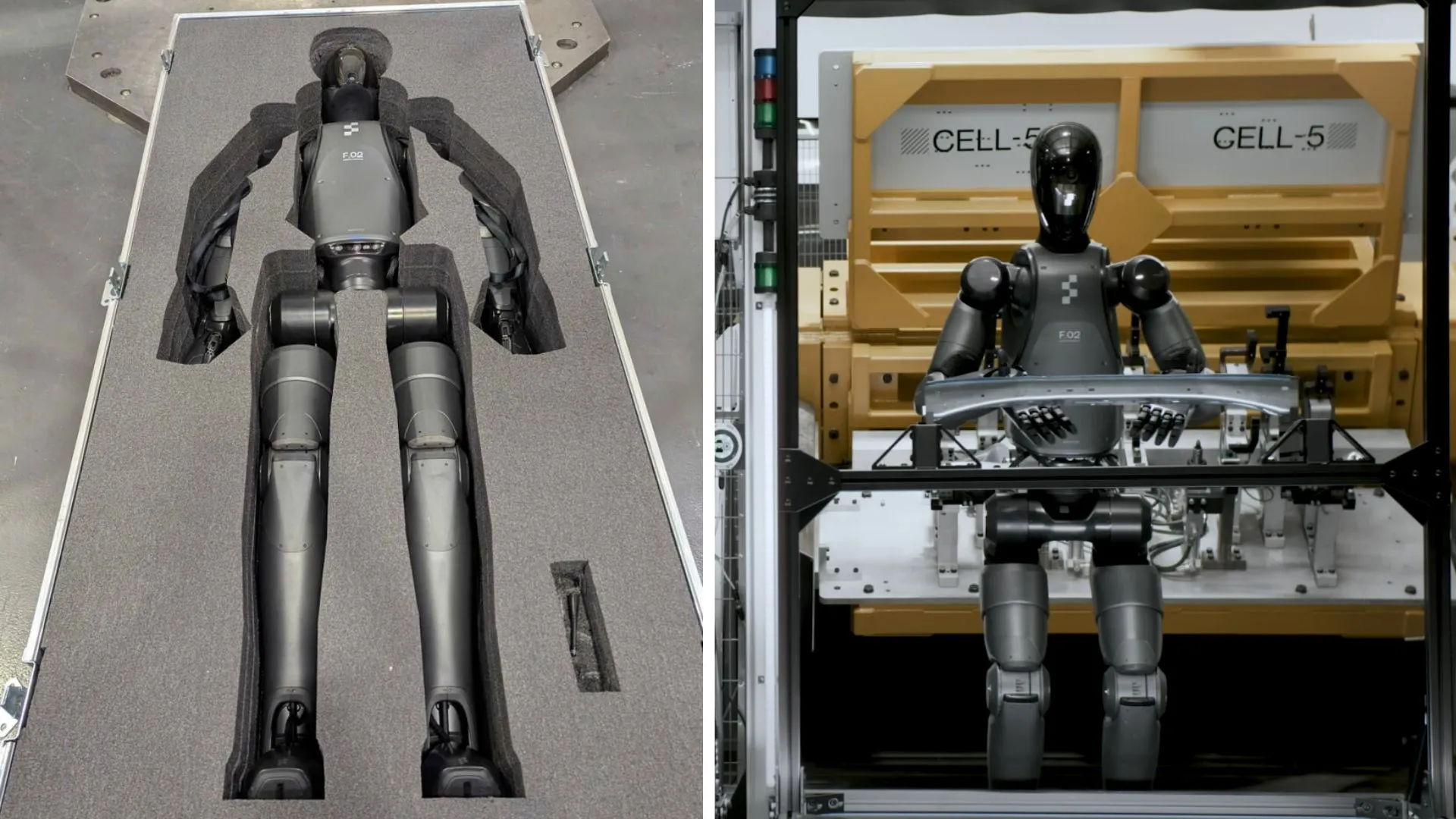

How Multimodal Inspection Robots Work

1. Multimodal Sensing Fusion

These robots don't just “see”—they feel, analyze, and adapt. By merging thermal imaging, 3D scanning, and vibration sensors, they detect everything from paint imperfections to structural weaknesses. For instance, BMW's AI-powered vision systems snap 100,000 photos per car in 100 seconds, flagging scratches or dents invisible to humans .

2. Real-Time Data Analytics

Every scan feeds into BMW's centralized quality database, where machine learning models crunch numbers to spot trends. If a welding robot shows a 0.01% deviation in torque, the system flags it instantly, preventing cascading defects .

3. Predictive Maintenance Integration

BMW's robots don't just inspect—they prevent. By monitoring equipment health (e.g., motor temperature curves), they predict failures before they happen. This reduces unplanned downtime by 500 minutes annually at plants like Regensburg .

4. Collaborative Robotics

Unlike traditional robots, BMW's systems collaborate with humans. For example, cobots (collaborative robots) handle repetitive tasks like screw tightening, while workers focus on complex assembly. Their edge detection tech ensures parts fit with ±0.03mm precision—sharper than a human hair .

5. Closed-Loop Quality Control

Defects aren't just logged; they trigger actionable insights. If a door panel fails a tactile test, the system alerts suppliers and adjusts production lines in real time. This “zero-defect mindset” has slashed warranty claims by 30% in recent years .

Why This Matters for Drivers

Safety First: Flawless welding and brake system inspections mean fewer recalls. BMW's post-crash data shows 99.6% structural integrity in crash tests, thanks to robot-verified welds .

Longevity: Sensors monitoring corrosion-prone areas (like undercarriages) extend vehicle lifespan by 2–3 years.

Consistency: Every BMW from Munich to Shenyang meets identical standards, whether it's a 3 Series or iX SUV.

5 Steps to Implement BMW-Style Quality Control

Deploy Multimodal Sensors

Use thermal cameras + LiDAR for 360° part analysis.

Example: BMW's paint shops use 100,000+ photo scans to catch paint bubbles .

Train AI Models on Historical Data

Feed algorithms 5+ years of defect logs to recognize patterns.

Integrate Predictive Maintenance

Monitor equipment health hourly (e.g., robotic arm torque sensors).

Adopt Collaborative Robotics

Pair cobots with humans for tasks requiring dexterity (e.g., interior assembly).

Build a Feedback Loop

Use defect data to redesign weak points (e.g., reinforced A-pillars after crash simulations).

Top Tools for Multimodal Quality Control

| Tool | Use Case | Accuracy |

|---|---|---|

| BMW's GOM Scanner | Full-vehicle 3D mapping | 99.9% |

| DeepSeeK-V3 AI | Surface defect classification | 99.6% |

| Siemens MindSphere | Predictive maintenance analytics | 98.2% |

The Future of Automotive QA

BMW's milestone isn't static. They're testing AI-driven “digital twins” that simulate vehicle behavior under extreme conditions. Imagine a robot predicting how a door hinge will wear over 100,000 km—before it's even built .

For manufacturers, this signals a shift: quality isn't a cost—it's an investment. BMW's 99.6% defect rate proves that automation, when paired with human ingenuity, can redefine excellence.