The fusion of cutting-edge algorithms and real-world machines is driving a new era. At the heart of this revolution is Physical AI, a field that blends perception, reasoning, and motion. By embedding intelligence directly into robots, companies achieve unmatched autonomy and precision. The global robotics market is set to hit $214 billion by 2030, thanks largely to Physical AI. Today, we explore key applications that prove why Physical AI matters.

What Is Physical AI and Why It Matters

Physical AI refers to systems where algorithms control mechanical components in real time. These robots sense their environment, learn on the fly, and adapt their actions without human input. Unlike purely software AI, Physical AI must handle noise, friction, and unpredictable scenarios. It powers products from self-driving cars to smart factory arms. For consumers, this means safer, faster, and more reliable solutions.

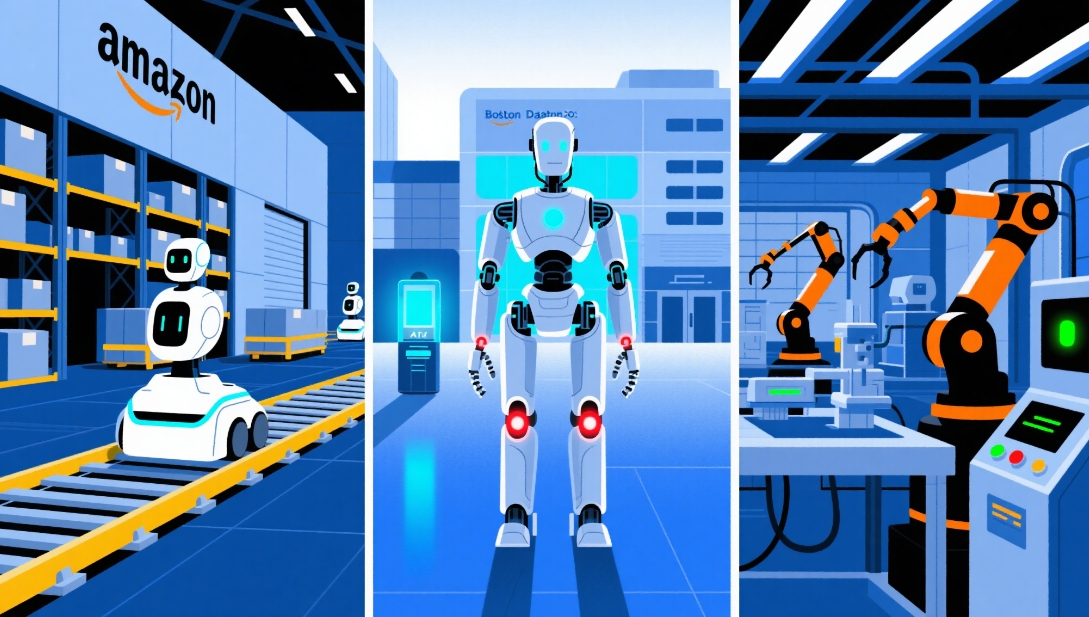

Warehouse Automation: The Rise of Physical AI

Today’s fulfillment centers use fleets of smart machines powered by Physical AI. Amazon Robotics bots navigate dynamic aisles, avoid obstacles, and adjust routes instantly. They combine vision, mapping, and planning in one package. These systems cut order-picking times by up to 50%, boosting throughput. Many startups now mimic this success, leveraging Nvidia Physical AI platforms for GPU-accelerated learning on the edge.

Case Study: Amazon Robotics

Amazon deployed tens of thousands of mobile robots in its warehouses. These robots collaborate with human workers, moving shelves and delivering goods. Since implementation, Amazon cut labor costs by 20% and improved order accuracy to 99.9%.

Humanoid Heroes: Physical AI in Bipedal Machines

Boston Dynamics’ Atlas robot showcases the agility of Physical AI Robot designs. Atlas can jump, dance, and recover from pushes without pre-programmed scripts. Its onboard AI processes sensor data at hundreds of hertz, making split-second decisions. By replicating human motion, Atlas paves the way for disaster response, site inspections, and personal assistance.

Precision Arms: Manufacturing with Physical AI

In factories, robotic arms equipped with Physical AI Companies technology handle welding, painting, and assembly. They learn from expert craftsmen, refining their strokes to perfection. Smart arms inspect parts in real time, detecting defects smaller than a human hair. This reduces scrap rates and delivers uniform quality across thousands of units.

Future Outlook: The Rise of Generative Physical AI

As we look ahead, Generative Physical AI will reshape design and prototyping. Robots will not only perform tasks but also suggest improvements to their own hardware. Imagine a self-optimizing assembly line where machines redesign grippers for better grip. This next phase will unlock new levels of efficiency across industries.

FAQs

What is the difference between Physical AI and traditional robotics?

Physical AI adds learning and adaptation directly into mechanical systems, while traditional robots follow fixed scripts.

Which industries benefit most from Physical AI?

Manufacturing, logistics, healthcare, and agriculture see the fastest gains from Physical AI applications.

Are Physical AI robots safe to work alongside humans?

Yes. Modern Physical AI systems have built-in sensors and collision-avoidance to ensure human safety.

How can businesses invest in Physical AI?

They can partner with Physical AI Companies, adopt turnkey Physical AI Products, or develop in-house Physical AI Assistant solutions.

Conclusion

Physical AI is not a futuristic dream—it’s here now, revolutionizing robotics across every sector. From warehouse floors to factory lines and beyond, these intelligent machines deliver speed, precision, and resilience. As investment pours in and technology matures, Physical AI will become the new standard for autonomy. The robots of tomorrow are alive today, powered by Physical AI.