The rise of AI Automated systems is redefining production. Industrial robots now handle precise tasks around the clock. Companies adopt AI Automated lines to boost flexibility. Less downtime means higher throughput. This article explores trends, case studies, and economic impacts of AI Automated factories.

AI Automated Robotics Trends in Production

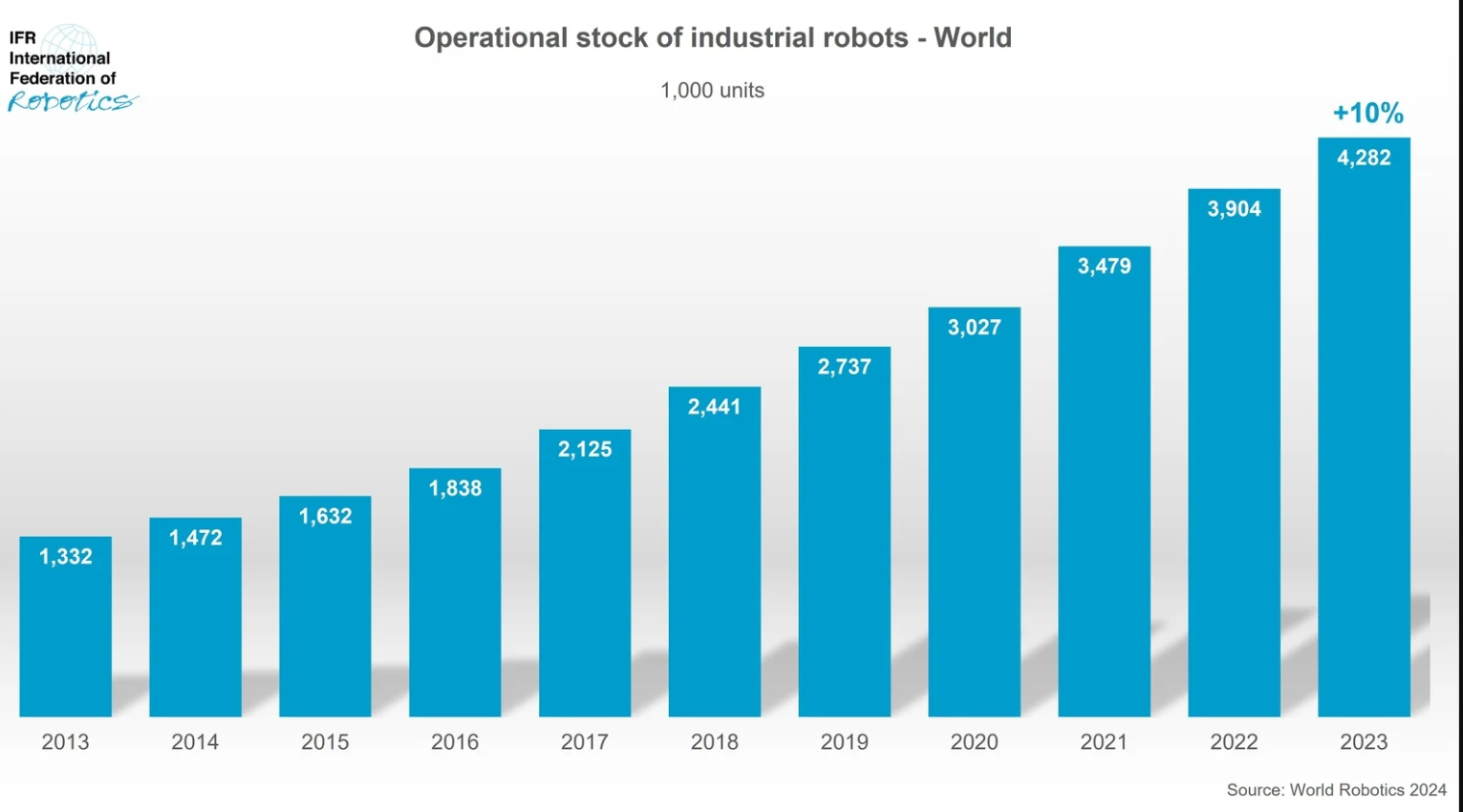

Worldwide, factories host over 4.28 million industrial robots. That’s a 10% year-on-year increase. In 2023 alone, 541,302 new units were installed. This rapid growth shows the power of AI Automated systems in manufacturing.

Robots now adapt to new tasks without reprogramming. Sensors and vision systems guide arms with millimeter precision. This is one of the best ai automation examples in modern plants. AI-driven quality checks reduce defects before parts leave the line.

One facility runs fully unmanned. Robots load PCBs, solder components, and inspect finishes. The line operates 24/7. Maintenance is scheduled only when AI detects tool wear. AI controls spray nozzles with dynamic adjustments. Color consistency now exceeds 99.5%. Workers oversee operations remotely. This shift highlights AI Automated Testing in real paint environments.Case Studies: AI Automated Lights-Out Factories

Electronics Assembly

Automotive Painting

The global factory automation market will grow from $288.8 billion in 2024 to $312.1 billion in 2025. That’s an 8.1% CAGR. Automotive robotics alone will hit $11.81 billion in 2025 and $24.33 billion by 2034. Industrial robotics was valued at $47.8 billion in 2024. Forecasts predict $211.1 billion by 2034. This explosive growth shows how AI Automated systems drive investment and innovation.Economic Impact of AI Automated Production

High upfront costs slow adoption for small firms. Integrating legacy equipment can be complex. Cybersecurity risks must be managed when lines are networked. Training the workforce on AI tools is vital. Schools must include robotics and AI basics. Collaboration between industry and academia will ease the transition. Machine vision, reinforcement learning, and edge computing are key. These tools let robots make split-second decisions. Real-time data feeds optimize every station on the floor. This is one of the most compelling ai automation successes so far. In parallel, simulation software tests new layouts before physical installation. Digital twins mirror real factories for safe experiments. Expect deeper collaboration between humans and machines. Cobots will share workspaces safely. AI planning tools will schedule maintenance and supply deliveries automatically. In the next decade, nearly every OEM will run at least one lights-out plant. This vision of fully AI Automated manufacturing is within reach. It means using artificial intelligence to control and optimize production lines with minimal human intervention. Yes. While initial investment is high, reduced labor costs and higher uptime deliver ROI in 2–4 years. They use encryption, network segmentation, and continuous monitoring to guard against cyber threats. AI Automated manufacturing is transforming industry with smarter, faster, and more flexible production. Trends show rapid adoption of industrial robots. Case studies highlight lights-out lines that cut waste and boost quality. Economic forecasts predict strong market growth. Challenges remain, but collaboration and training will pave the way. The future of fully AI Automated factories is bright.Challenges and Future of AI Automated Factories

Key Technologies Behind AI Automated Systems

Looking Ahead: The Role of AI Automated Innovation

FAQs

What does AI Automated manufacturing mean?

Are AI Automated factories cost-effective?

How do companies secure AI Automated systems?

Summary