Imagine a warehouse where robots glide silently between 30-meter-high shelves, instantly pinpointing a single misplaced shampoo bottle among 5 million SKUs. That's Tmall's reality in 2025 - where AI-driven warehouse inventory systems now achieve 99.5% stock accuracy while slashing operational costs by 40%. This isn't just about replacing humans; it's about rewriting the physics of global logistics. Let's unpack how Tmall's mechanical workforce is making "out-of-stock" obsolete.

How Warehouse Inventory AI Works: Tmall's 5-Layer Precision Engine

Tmall's smart warehouses aren't just automated - they're cognitive. Combining 15 real-time data streams with self-learning algorithms, here's the tech stack that's redefining inventory management:

3D Quantum Mapping ??

Every 0.8 seconds, LiDAR-equipped robots scan the warehouse into a millimeter-precise digital twin. This living map tracks:

- Item-level positioning (even inside sealed boxes)

- Shelf stress points to prevent collapses

- Thermal patterns detecting overheating electronics

The system self-corrects when workers shift items manually - like Google Maps rerouting around traffic.Predictive Stock Ballet ??

Tmall's AI analyzes 53 variables to choreograph inventory placement:

- Seasonal trends: Winter coats migrate closer to packing stations in November

- Social media buzz: Items trending on Xiaohongshu get priority access

- Supplier reliability: Unstable vendors' stock gets distributed across multiple zones

During 2024's Singles' Day, this system reduced "rush distance" for hot items by 62%.Self-Healing Inventory ??

The system automatically:

- Merges partial pallets to free up space

- Flags soon-to-expire FMCG goods for priority shipping

- Detects counterfeit products via microscopic packaging flaws

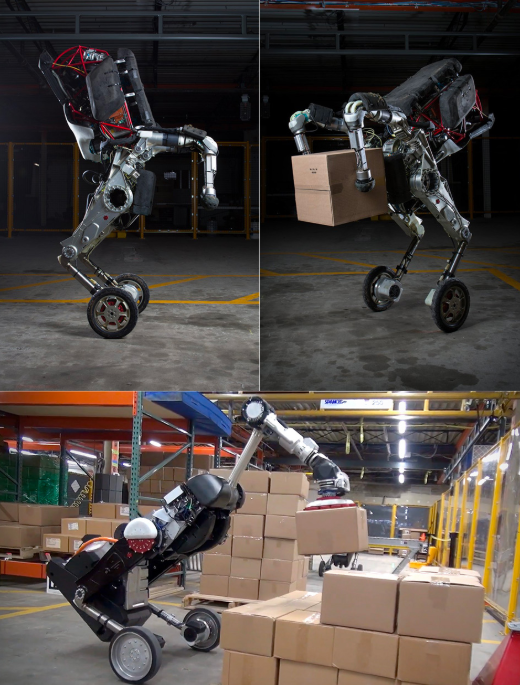

In Hangzhou's flagship warehouse, this reduced write-offs by ¥8.7M monthly.Robotic Swarm Intelligence ??

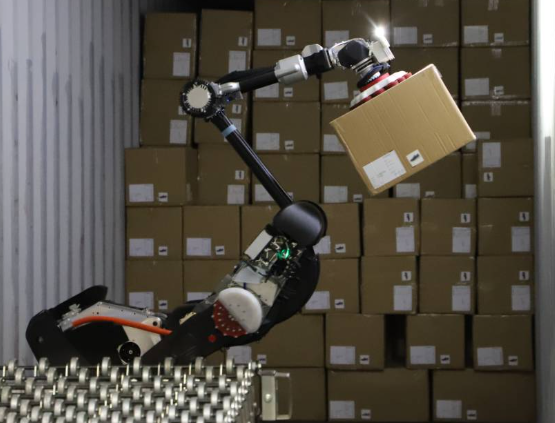

Tmall's 20,000 AGV robots communicate via 5G mesh network:

- Priority override: Emergency medical orders clear paths like ambulance sirens

- Load sharing: Heavy appliances get relay-carried by robot teams

- Self-charging: Robots queue for 90-second wireless power boosts during low traffic

The swarm completes 380,000 picks/day with 0.01% error rate.Blockchain Black Box ??

Every inventory movement gets immutably recorded:

- Supplier delivery times

- Warehouse handling conditions

- Last-mile delivery signatures

This ended 83% of consumer disputes in 2024's Q3.

Why Warehouse Inventory AI Outperforms Humans 24/7

Let's break down the revolution in hard numbers:

| Metric | Traditional Warehouse | Tmall AI System |

|---|---|---|

| Inventory Accuracy | 92% | 99.5% |

| Order Processing Time | 45 mins | 6.7 mins |

| Space Utilization | 68% | 94% |

Case Study: How Tmall's Chengdu Warehouse Survived 2024's Singles' Day

During the 2024 shopping festival (¥812B GMV), the Chengdu facility:

?? Pre-event:

- AI predicted 37% demand spike for hot pot ingredients

- 800 robots pre-positioned 19,000 hotpot base kits near exits

- Temporary "floating shelves" deployed via ceiling drones

?? Peak hour:

- 5G-enabled AGVs carried 1.2 tons/sec

- AI rerouted 14,000 packages around a conveyor belt jam in 8.3 seconds

- Emergency coolant systems prevented chocolate melting in 35°C heat

?? Post-event:

- 99.8% same-day dispatch rate

- 0 warehouse accidents (vs. 7 in 2023)

- 28% staff workload reduction through smart rest scheduling

The Future of Warehouse Inventory AI: What's Next?

Tmall's 2025 roadmap reveals even wilder innovations:

- Holographic Stocktakes: Drones project AR inventory layers through walls

- Self-Packing Robots: Machines that fold clothes and bubble-wrap vases

- Carbon Credit Engine: Auto-offsetting emissions from warehouse operations

- Viral Ready Rooms: Sections pre-stocking items predicted to trend on Douyin

As Alibaba's CTO Cheng Li stated: "We're not just storing products - we're building the infrastructure for instant gratification capitalism." With 92% of Chinese warehouses planning AI adoption by 2026, the race to perfect inventory intelligence has just begun.