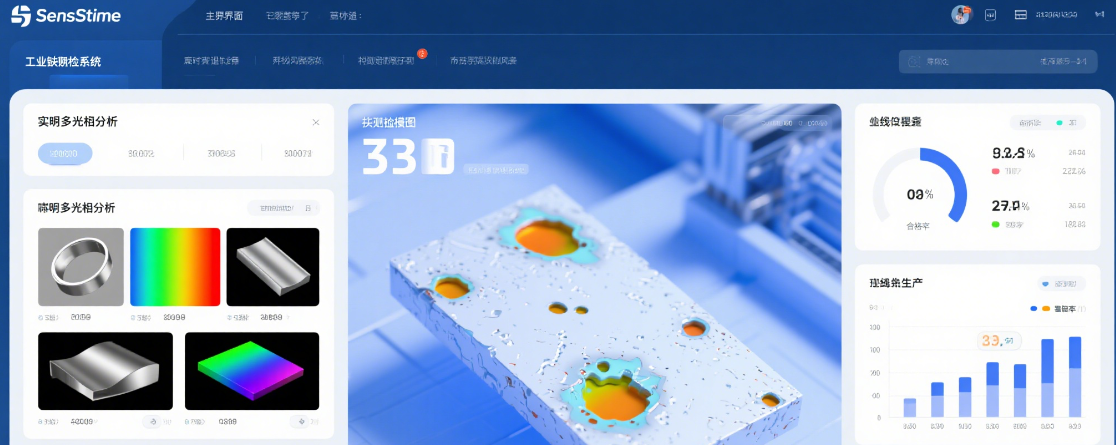

SenseTime Defect Detection: Three Breakthrough Technologies

Traditional machine vision is like using a magnifying glass to find ants - inefficient and exhausting. SenseTime's system gives factories "electronic compound eyes": Multimodal Data Fusion Engine

Combines visible light, X-ray, and 3D laser scanning to create "defect holograms." For semiconductor encapsulation, it simultaneously analyzes surface bubbles (optical) and internal cracks (X-ray tomography), improving detection accuracy from 92% to 99.1%. One electronics manufacturer saved ¥18M annually in rework costs. Few-Shot Learning Algorithms

Powered by SenseNova's foundation model, the system trains high-accuracy classifiers with just 500 labeled samples. For LCD panel inspection, it adapted smartphone screen defect databases to cut new production line training from 3 months to 2 weeks. Real-Time Edge Inference

The SensePPL engine delivers 10ms response times on industrial cameras. One auto parts plant processes 15 4K frames/second - 3x faster than GPU solutions with 40% lower power consumption.

SenseTime Defect Detection vs Traditional Solutions

| Metric | SenseTime | Traditional Vision |

|---|---|---|

| Inspection Speed | 15 fps (4K) | 5 fps (1080p) |

| Multi-Defect Detection | 23 types/frame | 5 types/frame |

| Model Update Cycle | 2-7 days | 1-3 months |

| Annual Maintenance | ¥80K/device | ¥150K/device |

?? Case Study: Lithium Battery Electrode Inspection

A battery manufacturer boosted coating defect detection from 97.5% to 99.3% using SenseTime's multispectral imaging. The system spots micron-level thickness variations invisible to the naked eye, while digital twin technology predicts equipment wear - reducing downtime by 62%.

5-Step Implementation Guide

STEP 1: Industrial Camera Matrix

Deploy 0.5μm-5μm resolution cameras based on production speed. One semiconductor plant uses eight 20MP global shutter cameras for 600 chips/minute full inspection. STEP 2: Defect Knowledge Graph

SenseMirage GAN generates 100K+ synthetic defect samples. A medical device company improved bone implant porosity detection F1-scores by 28%. STEP 3: Cloud-Edge Training

SenseCore enables OTA model updates. When new defects emerge, edge devices upload data and receive optimized models within 72 hours. One automaker reduced new model adaptation by 83%. STEP 4: Human-AI Interface

Custom OpenMMLab interfaces support AR annotation and 3D defect localization. Solar panel inspectors using gesture-controlled virtual magnifiers improved review efficiency by 140%. STEP 5: Quality Analytics

Integrated with MES systems, SenseThings predicts equipment failures. One LCD factory's AI dashboard detected coating machine anomalies 14 days early, preventing ¥6.5M losses.

Future Factories: SenseTime's Roadmap

?? Quantum Vision Sensors

By 2026, single-photon imaging will enable nanometer-scale detection - 1000x more sensitive for spotting 0.1nm chip wire deformations.

?? Global Quality Knowledge Federation

A blockchain-based defect database already connects factories in 12 countries. When Vietnam finds new weld bubbles, Chinese plants update models in real-time for "global immunity."

?? Self-Evolving Inspection Robots

Mobile AI stations with robotic arms autonomously plan inspection routes. One car body shop achieved 99.8% coverage (from 85%) with these.