BMW is not just building cars anymore — it's building the future. With its cutting-edge integration of BMW Robot technology, digital twin simulations, and humanoid assistants like Figure 02, BMW is rewriting the rules of automotive manufacturing. ??

How BMW Robot Tech Is Shaping the Factory Floor

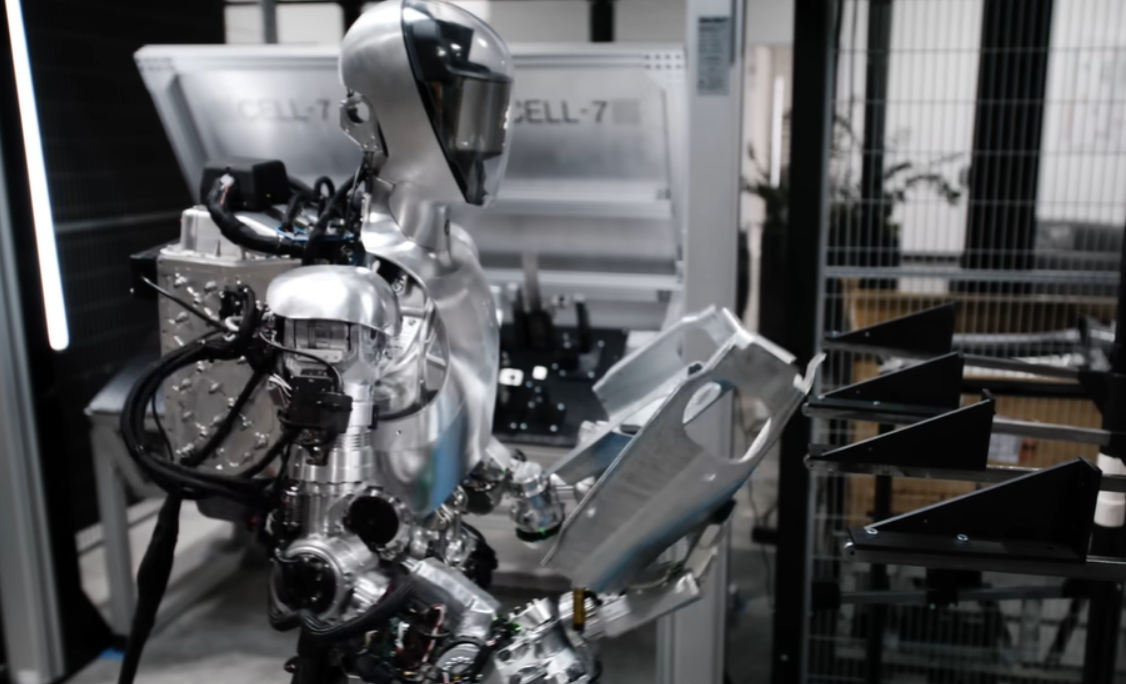

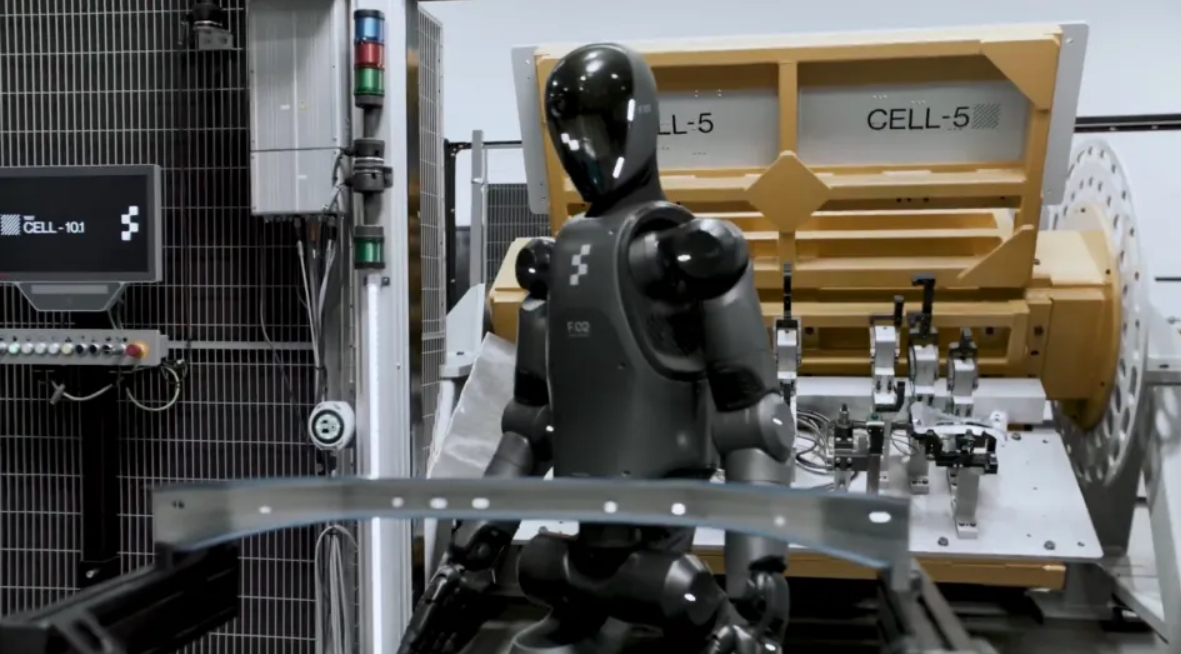

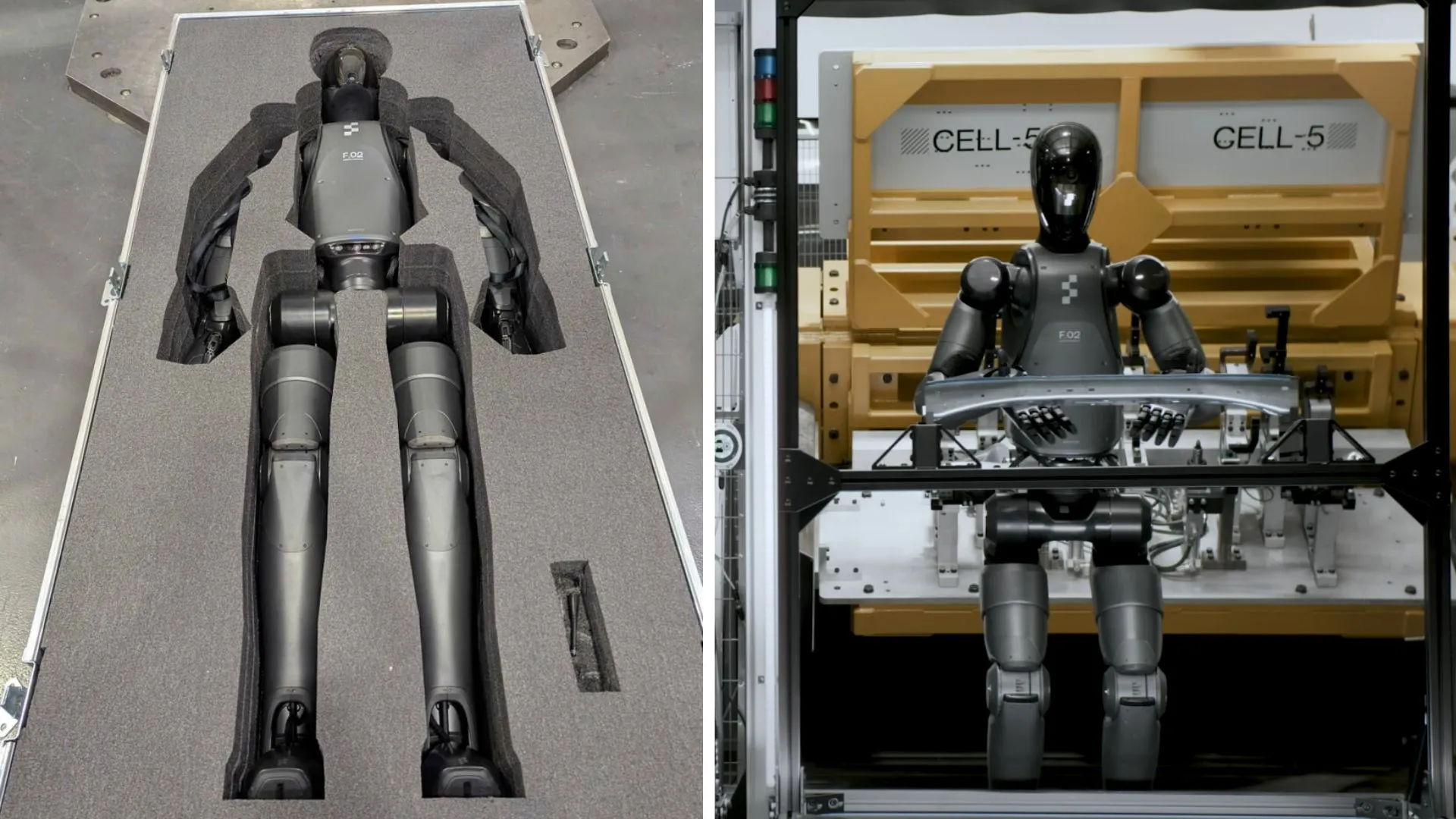

In 2025, BMW Robot Workers are becoming more than just mechanical arms. The company has introduced Figure 02 humanoid robots by Figure, integrated directly into its production line in Spartanburg, USA. These robots help with repetitive tasks like lifting, component delivery, and part inspections — all with human-like precision.

But the real magic lies in BMW’s use of digital twins. Powered by NVIDIA Omniverse, BMW creates virtual models of their factories and workflows. This allows the brand to simulate, test, and optimize every detail — from lighting to movement patterns — before a single bolt is tightened.

The BMW Robot AI makes it all even smarter. It adapts, learns, and improves how robots interact with the environment, creating a more efficient and ergonomic factory floor.

ETTA Expert Column: Inside the Figure BMW Robot Deployment

"We’ve made it our goal to eliminate ergonomic pain points for workers while improving efficiency across the board. Humanoid robots are one of our next big steps," says BMW’s Head of Innovation, Thomas Albrecht. "Figure 02 robots can do things traditional robots can’t — like opening doors or operating machinery meant for humans."

What Is the BMW Robot Figure 1 and How Is It Different?

The original BMW Robot Figure 1 paved the way for what we see today. Unlike the more advanced Figure 02, Figure 1 focused primarily on repetitive industrial tasks. Today, Figure One BMW Robot serves as the foundation of BMW’s modern robotic workflow.

The leap from Figure 1 to Figure 02 isn’t just about better tech — it’s about smarter, safer collaboration between humans and machines.

Digital Twins + AI: BMW’s Secret Weapon

Thanks to digital twin simulations via NVIDIA Omniverse, BMW now creates mirror versions of its factories in virtual space. Engineers use these simulations to spot inefficiencies, test new robot workflows, and train their BMW Humanoid Robot assistants.

These simulations also help reduce injury and fatigue. By analyzing motion and stress points in the virtual space, BMW tailors robotic assistance where it's needed most. It’s a perfect example of BMW Robotic Process Automation done right.

ETTA Point Analysis: Why BMW’s Robots Are Different

Real-time collaboration between humans and robots

Reduced production time by 30%

More than 500 simulations run daily via NVIDIA Omniverse

Better factory safety with posture-aware robot adjustments

Are BMW Robots Real? Yes, and They’re Here ??

BMW Robot Real is no longer just a phrase from sci-fi movies. Whether it’s robot dogs patrolling the plant or humanoid robots assembling interior components, these aren’t concepts — they’re already in action. ????

You may have even caught a BMW Robot Video showing the robots walking, working, and even interacting with human engineers. These machines are capable of identifying car parts, adjusting grip pressure, and recognizing hand signals — all powered by deep-learning AI.

And yes, there’s even a BMW Robot Dog modeled after Boston Dynamics’ four-legged machines — ideal for inspecting hard-to-reach areas.

ETTA Case Study: From BMW Robot Dishes to Final Assembly

In one case, BMW used humanoid robots to test the handling of sensitive components like navigation screens and dashboards. The results were impressive — a 98% success rate in accurate part placements, reducing rework dramatically. Even tasks like delivering boxed items or cleaning up (BMW Robot Dishes, anyone?) are now fair game.

Do BMW Robots Build Cars?

Yes — and more efficiently than ever. BMW Robot Car production is boosted by robotic assistants who manage repetitive and precision-heavy tasks. This has a direct impact on quality and speed, especially with luxury models like the BMW X series.

The BMW Robot Car Price hasn’t increased due to these innovations — in fact, production cost efficiency may help stabilize future pricing.

FAQs About BMW Robot Innovations

Q1: What Is the Most Advanced BMW Robot?

Figure 02 is currently the most advanced BMW Robot, offering humanoid capabilities and AI integration.

Q2: Is the BMW Robot Transformer Real?

While there’s no real BMW Transformer Robot, some marketing campaigns and art projects have shown robot-like cars. But don’t expect your 3 Series to turn into Optimus Prime yet. ??

Q3: Does BMW Use AI in Their Robots?

Absolutely. BMW AI Robot development is centered on deep learning, sensor fusion, and real-time decision-making.

Final Thoughts: BMW Robots Are More Than Tools — They’re Coworkers

BMW isn’t just building machines — it’s building an intelligent, flexible, and responsive future with BMW Robots. From humanoid helpers and robot dogs to powerful digital twin simulations, this is what innovation looks like when it's done right.

It’s not just “robots in Silent Running” anymore — these machines are walking, lifting, learning, and even thinking. ??

ETTA Summary: The Road Ahead

While people still ask, "Do Boston Dynamics Robots Use AI?" or "Does BMW Make Rolls Royce Engines?" — the truth is, BMW is already ahead. Robots are here, and they’re changing everything — from production to possibility.

BMW Robot is no longer a futuristic buzzword. It’s the present. And it’s only getting smarter. ??