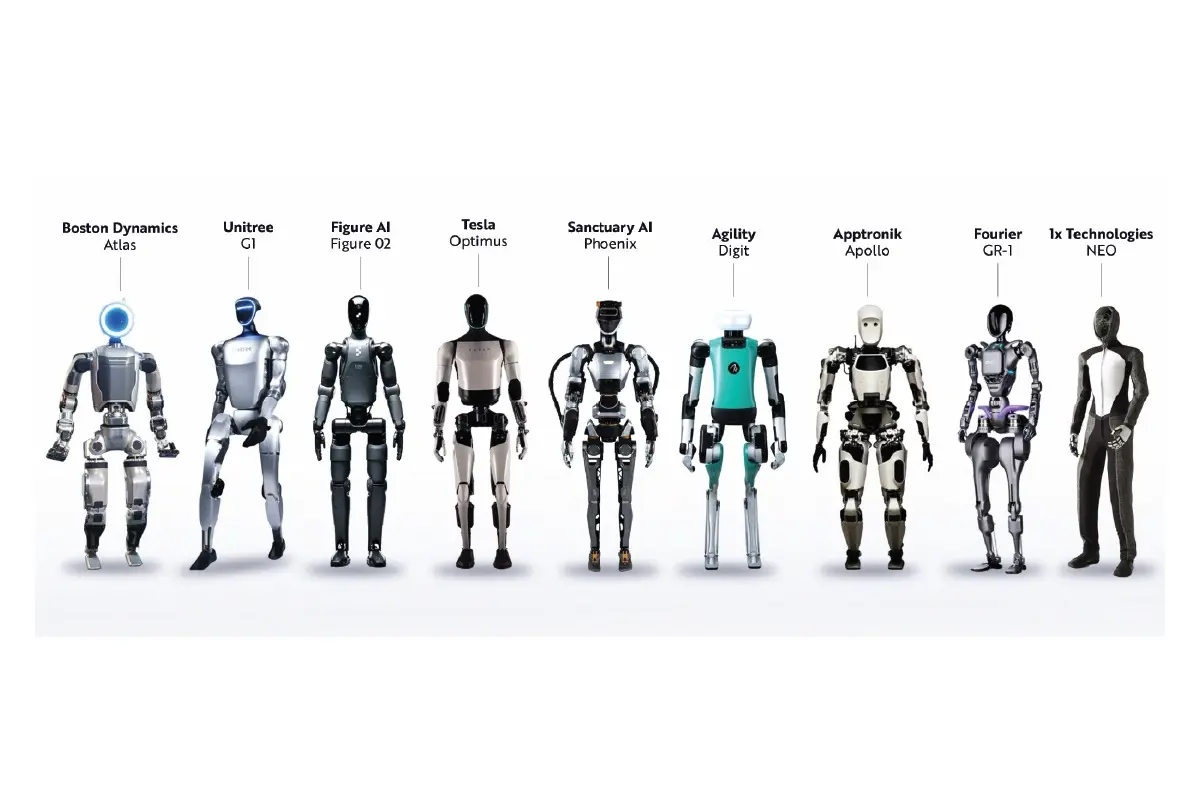

Welcome to the era of the Figure Factory, where intelligent humanoid robots redefine what’s possible in modern manufacturing. At the heart of this transformation is Figure AI, a company crafting robots with real-world dexterity, vision, and decision-making. This article explores how the “factory of the future” is being assembled today—powered by AI, robotics, and the ambition to change how humans work.

?? What Is the Figure Factory?

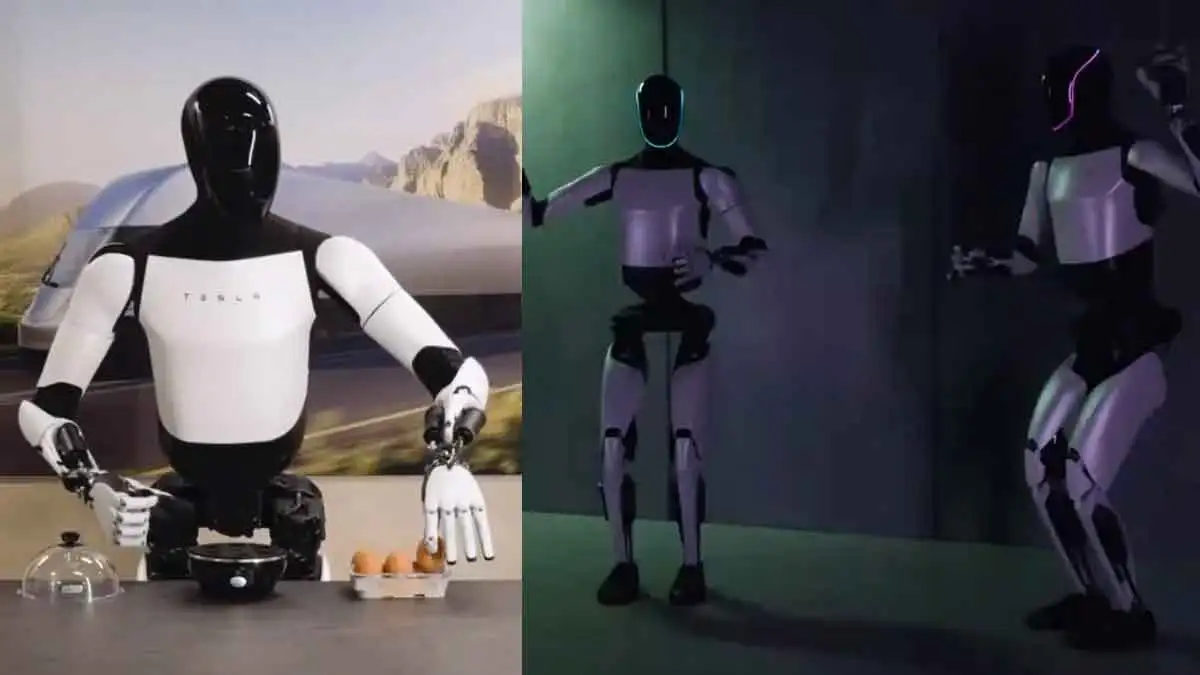

The term Figure Factory refers to a next-level industrial environment where humanoid robots handle dynamic tasks—packing, assembling, moving goods, and more. Unlike fixed-arm robots, these intelligent figures move freely, respond to unpredictable challenges, and work safely beside humans. Figure AI’s vision is simple: create general-purpose robots that integrate into every corner of production facilities.

?? Expert Insight

“The Figure Factory model doesn't just improve productivity; it redefines flexibility in automation,” says Dr. Mei Luo, Lead Engineer at Figure AI. “We’ve seen up to 40% increases in line efficiency using our humanoid bots.”

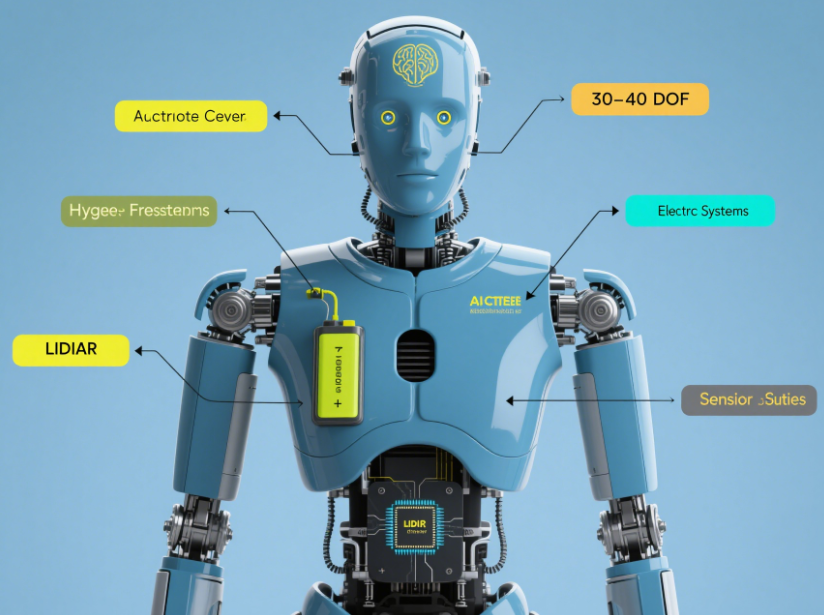

?? Core Components of a Figure Factory Robot

1. AI-Powered Vision

Advanced cameras and sensors help robots perceive their surroundings. They detect items, avoid obstacles, and adapt in real time.

2. Dexterous Hands & Arms

Inspired by human anatomy, Figure’s manipulators can grasp, rotate, and place items with care and precision—critical in electronics, logistics, and packaging industries.

3. Autonomous Mobility

Wheeled and bipedal mobility allows these bots to navigate tight spaces and dynamic floors, from warehouses to production lines.

4. Decision-Making Engine

AI software plans motion, adjusts grip, and selects optimal tasks. Learning algorithms improve the robot's performance every shift.

??? How a Figure Factory Works

Building a Figure Factory means integrating these humanoid robots into a smart system. Robots operate alongside conveyor belts, sensors, and software dashboards that monitor every task. Instead of rigid lines, production becomes modular and scalable.

Wondering how to calculate the workspace of a robot? Figure AI uses simulation software to map out reach, clearance, and cycle time—allowing engineers to pre-visualize layouts. This reduces installation time from months to weeks.

?? Real-World Impact

A mid-size appliance manufacturer replaced 30% of its human labor with Figure Factory humanoids. In under six months, production throughput grew by 27%, while maintenance downtime dropped significantly.

?? Can You Build a Figure Factory?

Yes—and sooner than you think. While large enterprises were early adopters, mid-sized businesses are jumping in with pilot programs. If you're considering whether you can make a robot using solid figures, Figure AI provides design kits and modular components. You don’t need a full robotics lab—just a plan and integration support.

Many also ask: What percentage of robots work in factories? Today, around 70–75% of all industrial robots operate in manufacturing. But with the rise of general-purpose bots, that number is expected to grow rapidly in logistics, food processing, and even healthcare settings.

????? From Roblox to Reality

Younger audiences might first encounter the concept through Figure Factory Roblox—a popular simulation game that mirrors real-world production flows. This playful tool helps train future engineers on how robots function in modular, automated environments.

?? Why the Figure Factory Matters

Modern industry needs flexibility, precision, and cost-efficiency. The Figure Factory answers that call. By combining AI, hardware, and modular design, Figure AI makes it possible to launch smart, adaptive lines that evolve with demand. You no longer need thousands of units to justify automation—just smart integration.

Curious minds still wonder: How to make robot using solid figures? It starts with blueprints, 3D models, and open APIs. Figure AI allows engineers to build, test, and deploy within their factory systems without starting from scratch.

?? Summary

The Figure Factory isn’t science fiction—it’s being built today. Powered by humanoid robots with vision, agility, and decision-making, this model allows for rapid scaling, reduced costs, and safer, more efficient production. Whether you're exploring robotics, designing your own workflow, or considering automation, the future belongs to those who build smarter—and the Figure Factory leads the way.