Imagine a world where production lines never halt, where precision is guaranteed, and where maintenance is predictive rather than reactive. This is not a distant future fantasy; it is the reality being built today by advanced robotic service solutions. At the heart of this industrial evolution is the ability to effectively Service ABB Robot systems, a critical skill for maximizing uptime and ROI in modern manufacturing. This comprehensive guide delves into the what, why, and how of maintaining these sophisticated machines, offering insights you won't find anywhere else.

What Does It Mean to Service ABB Robot Systems?

To Service ABB Robot equipment extends far beyond simple repairs. It encompasses a holistic lifecycle management approach, including scheduled preventive maintenance, real-time diagnostics, software updates, mechanical calibration, and emergency troubleshooting. These systems, comprising articulated, SCARA, and delta robots, are complex investments. Proper servicing ensures they operate at peak performance, safeguarding their accuracy, which can be precise to within microns, and extending their operational life by years. Neglecting this aspect can lead to catastrophic downtime costs, which can run into tens of thousands of dollars per hour in an automotive assembly plant.

The Unseen Economic Impact of Professional Robot Servicing

Many facilities managers view servicing as a cost center. However, a paradigm shift is occurring, where smart maintenance is recognized as a massive profit protector. A well-serviced ABB robot minimizes scrap from inaccuracies, reduces energy consumption by ensuring optimal motor performance, and prevents the massive financial losses associated with unplanned production stops. Furthermore, a complete service history significantly boosts the resale value of the robot, should you ever decide to upgrade your fleet. This financial perspective is often the most compelling argument for investing in a rigorous Service ABB Robot program.

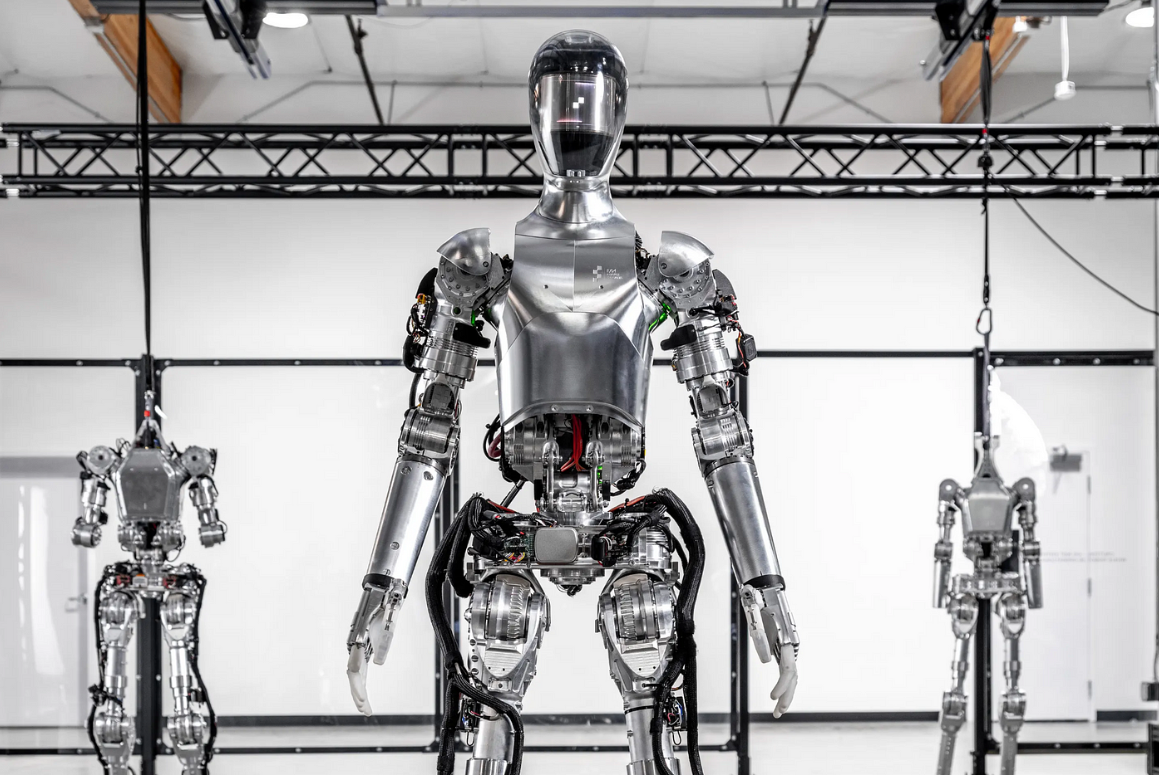

Beyond the Factory Floor: The Expanding Role of Service Robotics

While industrial automation is a primary application, the principles of maintenance and reliability are echoing in other sectors. Just as we Service ABB Robot arms for manufacturing, the future will demand similar expertise for assistive machines. The rise of sophisticated helper robots, similar to the concepts explored in discussions about why a service dog robot is the future of assistance, highlights a broader trend. These robots will require even more nuanced servicing, blending traditional mechanical skills with advanced AI and human-interaction diagnostics.

The Complete Service ABB Robot Maintenance Protocol

Preventive Maintenance Check

This involves a scheduled series of actions: inspecting and replacing grease in gearboxes, checking belt tensions, verifying brake function, and cleaning or replacing filters. Each robot model has a specific PM schedule outlined in its manual. Regular preventive maintenance can reduce unexpected breakdowns by up to 75% according to industry studies.

Mechanical Calibration

Over time, mechanical components can drift. Absolute Accuracy calibration or similar processes are used to restore the robot's positional precision to its original factory specifications, ensuring every movement is perfect. Modern calibration techniques can now achieve repeatability within 0.02mm, crucial for precision manufacturing applications.

Controller and Software Updates

The robot's brain, the controller, requires regular updates. This includes installing the latest firmware patches for security and performance and backing up and optimizing the program code that runs the automated tasks. Many facilities overlook cybersecurity updates, leaving their robots vulnerable to potential digital threats.

Performance Benchmarking

After servicing, it's crucial to run standardized test cycles to benchmark performance against original specifications. This includes checking cycle times, positional accuracy, payload capacity, and energy consumption. Documenting these metrics creates a valuable historical record for predictive maintenance algorithms.

Choosing the Right Partner for Your Service ABB Robot Needs

Not all service providers are created equal. When selecting a partner, consider these critical factors:

Certification: Look for ABB-certified technicians with current training credentials

Response Time: Verify their guaranteed response times for critical issues

Documentation: Ensure they provide comprehensive service reports with before/after metrics

Preventive Approach: The best partners offer predictive maintenance suggestions, not just fixes

Parts Availability: Check their inventory of genuine ABB replacement parts

Future Trends in Robot Servicing

The field of Service ABB Robot maintenance is evolving rapidly with several emerging trends:

Augmented Reality Assistance

Technicians are beginning to use AR glasses that overlay maintenance instructions directly onto their field of view, reducing errors and speeding up complex procedures.

AI-Powered Predictive Maintenance

Advanced algorithms now analyze vibration patterns, temperature fluctuations, and performance data to predict failures before they occur, sometimes weeks in advance.

Remote Diagnostics

With secure connections, many diagnostics and even some repairs can now be performed remotely by expert technicians thousands of miles away, significantly reducing downtime.

Frequently Asked Questions (FAQs)

Q: How often does my ABB robot need professional servicing?

A: The frequency depends on the robot's workload and operating environment. A general rule of thumb is an annual preventive maintenance check for robots in continuous operation. However, always consult the specific maintenance chapter in your robot's product manual for the manufacturer's recommended schedule. Robots in harsh environments (high dust, temperature extremes, etc.) may require quarterly servicing.

Q: Can I perform any maintenance tasks in-house to reduce costs?

A: Yes, certain basic tasks can be handled by trained plant personnel. This includes daily or weekly visual inspections for obvious damage, cleaning the robot's exterior and joints to prevent contaminant buildup, and monitoring error logs. However, any task involving internal components, recalibration, or software deep-dives should be reserved for certified experts to avoid voiding warranties or causing damage. ABB offers training programs for in-house maintenance teams to handle intermediate-level tasks.

Q: What are the most common signs that my ABB robot needs immediate servicing?

A: Key warning signs include a noticeable decrease in positional accuracy (especially repeatability), unusual noises from gears or motors (grinding, clicking, or whining sounds), increased vibration during movement, frequent and unexplained error codes, any oil leaks from the arm or gear units, and sudden increases in energy consumption. If you observe any of these, it's time to call a professional immediately to prevent further damage.

Q: How long does a typical ABB robot service take?

A: The duration varies significantly based on the service type. A basic preventive maintenance check might take 4-8 hours for a single robot. More comprehensive servicing with calibration could take 1-2 days. Major overhauls or component replacements might require 3-5 days. Always plan for at least 20% additional time for unexpected findings during the service process.

Q: What's the cost range for professional ABB robot servicing?

A: Service costs depend on robot size, complexity, and service type. Basic PM starts around $1,500-$3,000 per robot. Comprehensive annual services typically range $3,000-$7,000. Major overhauls can cost $10,000+. Emergency services often carry premium rates of 1.5-2x standard rates. Many providers offer service contracts that can reduce costs by 15-30% through scheduled, bulk servicing.

Conclusion: The Smart Investment in Service ABB Robot Maintenance

In today's competitive manufacturing landscape, the difference between industry leaders and struggling operations often comes down to equipment reliability. Implementing a robust Service ABB Robot program isn't an expense—it's an investment with measurable ROI. By preventing catastrophic failures, maintaining precision, and extending equipment life, proper servicing pays for itself many times over. As robotics technology advances, the service requirements will become more sophisticated, making the choice of service partner even more critical. The factories that embrace this maintenance mindset today will be the productivity leaders of tomorrow.