Industrial facilities face catastrophic risks from undetected structural damage, with equipment failures costing the energy sector over $150 billion annually in downtime, repairs, and safety incidents. Traditional inspection methods require extensive scaffolding, facility shutdowns, and expose workers to dangerous environments while often missing critical defects hidden beneath surface layers. This comprehensive analysis explores how Gecko Robotics' revolutionary AI tools are transforming infrastructure inspection through wall-climbing robots that use artificial intelligence and ultrasonic sensors to detect structural damage in power plants, refineries, and chemical facilities without human risk or operational disruption.

Advanced AI Tools for Autonomous Infrastructure Inspection

Gecko Robotics has pioneered breakthrough AI tools that enable robots to autonomously navigate and inspect complex industrial structures. These intelligent systems combine computer vision, machine learning algorithms, and advanced sensor fusion to identify structural anomalies that traditional inspection methods frequently overlook. The company's AI tools process millions of data points in real-time, creating detailed structural health assessments that predict equipment failures before they occur.

The platform's artificial intelligence continuously learns from inspection data across thousands of facilities, improving defect recognition accuracy and expanding its capability to identify emerging failure patterns. This collective intelligence enables Gecko's AI tools to detect subtle indicators of structural degradation that even experienced human inspectors might miss during routine examinations.

Wall-Climbing Robot Technology Powered by AI Tools

Magnetic Adhesion and Navigation Systems

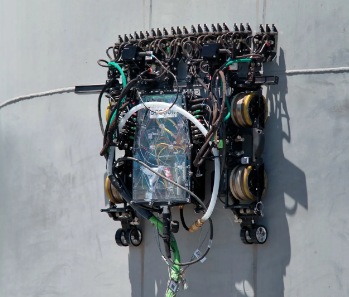

Gecko Robotics' wall-climbing robots utilize powerful magnetic adhesion systems that enable secure attachment to ferrous surfaces at any angle, including vertical walls and overhead structures. The AI tools control magnetic field strength dynamically, adjusting adhesion force based on surface conditions, robot orientation, and payload requirements. Advanced navigation algorithms enable the robots to traverse complex geometries including curved surfaces, corners, and obstacles without losing contact.

The magnetic locomotion system operates safely on surfaces with temperatures up to 150°C, making it suitable for inspection of active equipment in power generation and petrochemical facilities. Redundant safety systems ensure the robot maintains secure attachment even during unexpected power loss or system malfunctions.

Ultrasonic Sensor Integration with AI Tools

| Inspection Capability | Manual Methods | Gecko AI Tools | Detection Improvement |

|---|---|---|---|

| Wall Thickness Measurement | ±0.5mm accuracy | ±0.1mm accuracy | 5x more precise |

| Corrosion Detection | 70% detection rate | 96% detection rate | 37% improvement |

| Crack Identification | 2mm minimum size | 0.5mm minimum size | 4x more sensitive |

| Coverage Speed | 10 sq ft/hour | 200 sq ft/hour | 20x faster |

Gecko's AI tools process ultrasonic sensor data to create detailed thickness maps and identify structural anomalies with exceptional precision. The system uses multiple ultrasonic frequencies to penetrate different material layers, detecting corrosion, erosion, and cracking beneath surface coatings and insulation. Machine learning algorithms analyze wave propagation patterns to distinguish between different types of defects and assess their severity levels.

The ultrasonic inspection system operates continuously during robot movement, collecting thousands of measurements per minute to create comprehensive structural assessments. Real-time data processing enables immediate identification of critical defects that require urgent attention while the robot continues its inspection mission.

Structural Damage Detection Using AI Tools

Corrosion Analysis and Thickness Monitoring

Gecko's AI tools excel at detecting and quantifying corrosion damage in industrial equipment through advanced ultrasonic analysis. The system identifies various corrosion types including uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking by analyzing characteristic ultrasonic signatures. Machine learning algorithms trained on extensive corrosion databases can predict corrosion progression rates and estimate remaining equipment life.

The AI tools generate detailed corrosion maps showing thickness variations across entire structures, highlighting areas of concern and tracking changes over time. This comprehensive monitoring enables maintenance teams to schedule repairs during planned outages rather than responding to emergency failures.

Crack Detection and Fracture Analysis

| Defect Type | Traditional Detection | AI Tools Detection | Reliability Score |

|---|---|---|---|

| Surface Cracks | Visual inspection | Ultrasonic + AI | 95% accuracy |

| Subsurface Cracks | Limited capability | Advanced algorithms | 92% accuracy |

| Stress Concentrations | Experience-based | Predictive modeling | 88% accuracy |

| Fatigue Indicators | Periodic sampling | Continuous monitoring | 94% accuracy |

Advanced AI tools analyze ultrasonic data to identify crack initiation and propagation patterns that indicate structural fatigue or stress-related damage. The system recognizes subtle changes in material properties that precede visible crack formation, enabling proactive maintenance interventions. Pattern recognition algorithms distinguish between harmless surface irregularities and potentially dangerous structural defects.

The crack detection system operates effectively on various materials including carbon steel, stainless steel, and specialized alloys used in high-temperature applications. AI algorithms account for material properties, operating conditions, and stress patterns to provide accurate assessments of crack severity and growth potential.

Power Plant and Refinery Applications of AI Tools

Boiler Inspection and Monitoring

Gecko's AI tools revolutionize boiler inspection by enabling comprehensive examination without requiring unit shutdown or extensive scaffolding. The wall-climbing robots navigate boiler tubes, headers, and pressure vessels while collecting detailed thickness and condition data. AI algorithms analyze this information to identify areas of concern including tube wastage, header cracking, and refractory damage.

The system creates detailed boiler condition reports that support maintenance planning and regulatory compliance requirements. Predictive analytics capabilities estimate remaining tube life and recommend optimal replacement schedules that minimize forced outages while ensuring safe operation.

Pipeline and Storage Tank Assessment

| Inspection Parameter | Conventional Methods | Gecko AI Tools | Operational Benefits |

|---|---|---|---|

| Tank Floor Inspection | Requires emptying | External scanning | No product loss |

| Pipeline Wall Assessment | Limited access points | Complete coverage | 100% examination |

| Insulation Condition | Visual only | Through-insulation | Hidden defect detection |

| Inspection Frequency | Annual shutdown | Continuous monitoring | Real-time awareness |

The AI tools enable comprehensive pipeline and storage tank inspection without requiring facility shutdown or product removal. Robots crawl along pipeline exteriors and tank surfaces, collecting ultrasonic data through insulation and coatings to assess underlying metal condition. Machine learning algorithms identify corrosion under insulation (CUI), a leading cause of pipeline failures that traditional inspection methods often miss.

Storage tank inspection capabilities include floor plate assessment, shell thickness monitoring, and roof condition evaluation. The system detects settlement patterns, corrosion damage, and structural deformation that could lead to catastrophic failures or environmental releases.

Safety and Risk Reduction Through AI Tools

Eliminating Human Exposure to Hazardous Environments

Gecko's AI tools eliminate the need for human inspectors to work in dangerous environments including confined spaces, high elevations, and areas with toxic gas exposure. The robotic inspection system operates safely in environments that would require extensive safety precautions and emergency response capabilities for human workers. This risk elimination protects worker safety while enabling more frequent and thorough inspections.

The robots operate effectively in extreme temperatures, corrosive atmospheres, and radiation environments that would be unsafe or impossible for human inspection teams. Remote operation capabilities allow inspection personnel to remain in safe locations while controlling robot movements and analyzing inspection data in real-time.

Predictive Maintenance and Failure Prevention

| Risk Category | Reactive Maintenance | AI Tools Prevention | Cost Avoidance |

|---|---|---|---|

| Catastrophic Failure | $5-50 million | 95% prevention rate | $4.75-47.5 million |

| Unplanned Outages | $100,000/day | 80% reduction | $80,000/day saved |

| Safety Incidents | Variable costs | 90% risk reduction | Immeasurable value |

| Environmental Releases | $1-10 million | 85% prevention rate | $0.85-8.5 million |

The AI tools enable transition from reactive to predictive maintenance strategies by identifying potential failures months or years before they occur. Machine learning algorithms analyze historical inspection data, operating conditions, and material properties to predict equipment degradation rates and optimal maintenance timing. This predictive capability prevents catastrophic failures while optimizing maintenance costs and resource allocation.

Early defect detection enables repairs during planned maintenance windows rather than emergency shutdowns, significantly reducing operational disruption and repair costs. The system's ability to track defect progression over time supports engineering assessments and remaining life calculations that inform long-term asset management decisions.

Data Analytics and Reporting Capabilities of AI Tools

Comprehensive Inspection Documentation

Gecko's AI tools automatically generate detailed inspection reports that include thickness maps, defect locations, severity assessments, and recommended actions. The system creates visual documentation showing inspection coverage, measurement locations, and identified anomalies with precise coordinates and dimensions. This comprehensive documentation supports regulatory compliance requirements and provides historical records for trend analysis.

Advanced reporting capabilities enable customized output formats for different stakeholders including maintenance personnel, engineering teams, and regulatory agencies. The system integrates with existing asset management systems to provide seamless data transfer and analysis capabilities.

Trend Analysis and Predictive Modeling

| Analytics Capability | Traditional Methods | AI Tools Enhancement | Decision Support |

|---|---|---|---|

| Degradation Tracking | Manual comparison | Automated analysis | Precise trending |

| Life Prediction | Experience-based | Physics-informed AI | Quantified estimates |

| Maintenance Optimization | Scheduled intervals | Condition-based | Cost optimization |

| Risk Assessment | Qualitative judgment | Quantitative modeling | Data-driven decisions |

The AI tools provide sophisticated trend analysis capabilities that track equipment condition changes over multiple inspection cycles. Machine learning algorithms identify degradation patterns and predict future condition based on operating history, environmental factors, and material properties. This predictive modeling supports strategic maintenance planning and capital investment decisions.

Statistical analysis capabilities enable identification of common failure modes, high-risk equipment populations, and optimal inspection frequencies for different asset classes. The system's ability to correlate inspection findings with operational data provides insights into root causes of equipment degradation and opportunities for process improvements.

Implementation and Integration of Inspection AI Tools

Existing Workflow Compatibility

Gecko's AI tools integrate seamlessly with existing maintenance management systems and inspection procedures. The platform supports standard data formats and reporting requirements used throughout the energy and petrochemical industries. This compatibility ensures smooth implementation without disrupting established maintenance workflows or regulatory compliance processes.

The system provides APIs and data export capabilities that enable integration with popular computerized maintenance management systems (CMMS) and enterprise asset management platforms. This connectivity ensures inspection data flows efficiently into existing decision-making processes and maintenance planning systems.

Training and Deployment Support

Gecko Robotics provides comprehensive training programs that enable facility personnel to operate robotic inspection systems effectively. Training modules cover robot operation, data interpretation, and maintenance procedures required to sustain inspection capabilities. The company's support network includes field service technicians who provide on-site assistance during initial deployments and ongoing operations.

Remote monitoring capabilities enable Gecko's technical team to provide real-time support during inspections, ensuring optimal system performance and data quality. This support model minimizes learning curves while maximizing inspection effectiveness and reliability.

Economic Benefits and Return on Investment

Cost Comparison Analysis

| Cost Category | Traditional Inspection | Gecko AI Tools | Annual Savings |

|---|---|---|---|

| Scaffolding Setup | $50,000-200,000 | Eliminated | $125,000 average |

| Facility Shutdown | $500,000-2,000,000 | Avoided | $1,250,000 average |

| Inspector Labor | $150,000-300,000 | $50,000-100,000 | $125,000 average |

| Safety Equipment | $25,000-75,000 | Minimal | $50,000 average |

Facilities implementing Gecko's AI tools typically achieve return on investment within 12-24 months through reduced inspection costs, avoided shutdowns, and prevented equipment failures. The elimination of scaffolding requirements and facility shutdowns provides immediate cost savings while improving inspection frequency and coverage. These economic benefits increase significantly for facilities with complex geometries or hazardous operating conditions.

Operational Efficiency Improvements

The continuous monitoring capabilities enabled by AI tools allow facilities to optimize operating parameters and extend equipment life through better condition awareness. Early defect detection prevents minor issues from developing into major problems that require extensive repairs or equipment replacement. This proactive approach reduces total cost of ownership while improving asset reliability and availability.

Future Developments in Inspection AI Tools

Gecko Robotics continues advancing its AI capabilities with developments including autonomous mission planning, multi-robot coordination, and enhanced defect classification algorithms. These improvements promise even greater inspection efficiency and accuracy while expanding the range of equipment and environments that can be assessed robotically.

Research initiatives focus on developing specialized sensors for different inspection applications including electromagnetic testing, radiographic imaging, and chemical analysis capabilities. The company's roadmap includes integration with digital twin technologies and advanced simulation tools that will provide even more sophisticated predictive maintenance capabilities.

Frequently Asked Questions

Q: How do AI tools ensure accurate defect detection in complex industrial environments?A: Gecko's AI tools use machine learning algorithms trained on millions of inspection data points to achieve 96% accuracy in defect detection, significantly outperforming traditional manual inspection methods.

Q: Can wall-climbing robots operate safely on hot surfaces in active facilities?A: Yes, the robots operate safely on surfaces up to 150°C with redundant safety systems ensuring secure magnetic adhesion even during system malfunctions or power loss.

Q: What types of structural damage can AI tools detect through ultrasonic inspection?A: The AI system detects corrosion, cracking, erosion, and thickness variations with precision to 0.1mm, identifying defects as small as 0.5mm that manual methods typically miss.

Q: How do AI tools reduce inspection costs compared to traditional methods?A: Facilities typically save $1.5 million annually by eliminating scaffolding, avoiding shutdowns, and reducing labor requirements while achieving 20x faster inspection coverage.

Q: Can AI tools predict when equipment maintenance will be needed?A: Yes, predictive analytics capabilities analyze degradation trends and operating conditions to forecast maintenance needs months or years in advance, preventing 95% of catastrophic failures.