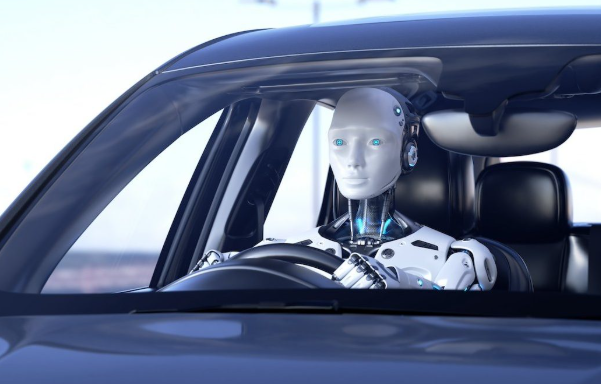

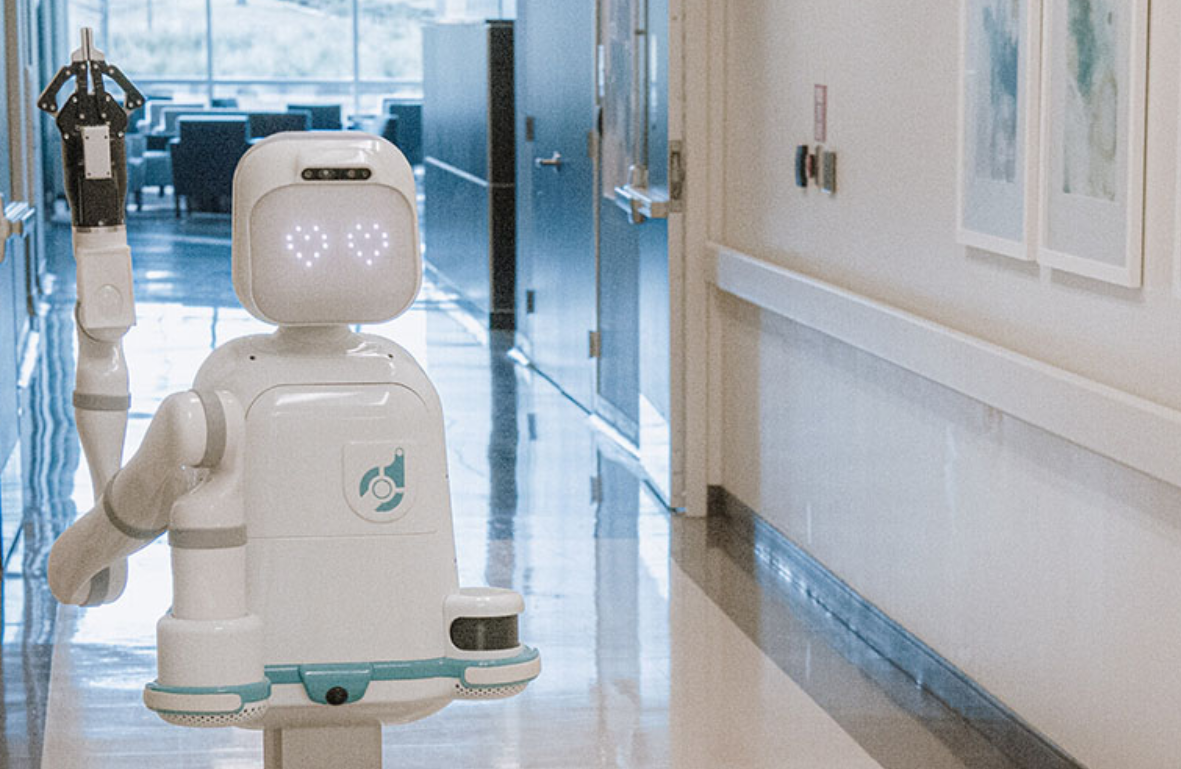

Imagine a world where human-like machines walk among us, capable of understanding complex environments and performing tasks with human-level dexterity. This vision is rapidly materializing through innovations in Humanoid Robot Specifications that define the capabilities of these biomechanical marvels. As AI-powered robotics accelerate from research labs to real-world applications, understanding these specifications becomes essential to grasp how androids will transform industries from healthcare to manufacturing. Unlike typical tech specs sheets, these parameters reveal profound insights about what it means to create artificial humans that navigate our physical world.

Core Components Defining Humanoid Robot Specifications

At the heart of every advanced android lies a sophisticated framework dictated by five critical specification domains:

1. Mobility & Kinematics

Degree-of-freedom (DoF) configuration forms the foundation of movement capabilities. State-of-the-art humanoids like Tesla's Optimus feature over 40 DoFs, with complex arrangements in:

Manipulator systems (12+ DoF hands with tactile sensors)

Locomotion systems (6-DoF legs with zero-torque passive joints)

Neck and torso articulation (8+ DoF for expressive movement)

2. Sensory Architecture

Modern systems integrate multimodal sensor arrays rivaling biological senses:

360° LiDAR with 200m range and 0.1° resolution

Multispectral cameras including thermal imaging

Inertial Measurement Units (IMUs) at 1000Hz sampling

Pressure sensor arrays with 2000+ points per hand

3. Processing & AI Infrastructure

The computational backbone enabling real-time cognition includes:

Custom neural processing units (NPUs) exceeding 100 TOPS

Distributed computing architecture with redundant systems

Multi-modal transformer models for embodied AI

Manufacturer Comparison: Pushing the Specifications Envelope

| Model | Height/Weight | Degrees of Freedom | AI Compute | Operational Time |

|---|---|---|---|---|

| Tesla Optimus Gen-2 | 173cm/73kg | 44 DoF | Neural Net Processor (20 TOPS) | 8 hours (continuous) |

| Boston Dynamics Atlas | 150cm/89kg | 28 DoF (hydraulic) | Edge AI System (15 TOPS) | 1 hour (high intensity) |

| UBTech Walker X | 145cm/77kg | 41 DoF | Qualcomm RB5 (15 TOPS) | 4 hours (mixed usage) |

| Apptronik Apollo | 167cm/72kg | 34 DoF | Custom AI Accelerator (17 TOPS) | 6 hours (normal operation) |

The rapid innovation cycle shows humanoid specifications improving at an unprecedented 78% annual pace, outpacing even Moore's Law during its peak. Where first-generation models required external power tethers, current iterations operate for 6-8 hours between charges while achieving power-to-mobility efficiency ratios matching biological systems.

Why Specifications Dictate Application Success

The Ergonomics Imperative

Critical environments demand anthropomorphic proportions optimized for human workspaces:

Shoulder-to-fingertip length between 60-75cm

Step height capacity ≥40cm for facility navigation

Object manipulation range: 0.5kg to 25kg payloads

Safety Certification Requirements

Industrial certification requires strict parameters:

Collision detection response < 50 milliseconds

Force-limited joints with continuous monitoring

ISO 13482 compliance for physical human-robot interaction

Environment Adaptability Standards

Operational specs must cover diverse scenarios:

IP ratings ≥54 for dust/water resistance

Temperature tolerance: -10°C to 50°C

Stability on slopes up to 20° inclination

Future Evolution of Humanoid Robot Specifications

Three revolutionary specification frontiers will define next-generation humanoids:

Biomimetic Actuation Systems

Muscle-like fiber actuators promise exponential improvements in:

Power density (300-400 W/kg vs. current 150 W/kg)

Compliance and impact absorption

Energy recovery through biomechanical emulation

Distributed Neural Architectures

Emerging spec frameworks move beyond centralized control:

Reflex-level processing in peripheral subsystems

Cross-modal sensory fusion with spatial awareness

Continuous learning capabilities without retraining

Multi-agent Interoperability

Swarm specifications for team coordination:

Shared situational awareness mapping

Behavior synchronization protocols

Collective load distribution systems

These advancements position humanoid specifications to achieve operational parity with human capabilities in complex environments within this decade, fundamentally redefining human-machine collaboration paradigms.

FAQs on Humanoid Robot Specifications

What's the relationship between degrees of freedom and functionality?

DoF determines movement complexity - while 28 DoF enables basic walking and grasping, 40+ DoF creates human-like dexterity. Current leaders achieve over 200 micro-movements per hand alone. Unlike industrial arms, humanoid configurations prioritize biomimetic articulation.

How do battery specs influence operational constraints?

Energy density limitations create significant tradeoffs. Tesla's 2.3kWh pack occupies 30% of torso volume yet delivers just 8 hours light-duty operation. Novel approaches include:

Distributed micro-batteries in limb segments

Kinetic energy regeneration (capturing 20% of motion energy)

Ultracapacitor systems for peak power demands

Why is sensory system resolution critical?

Environmental navigation requires sensing precision exceeding self-driving systems - Boston Dynamics' Atlas processes 700Gb sensor data per operation hour. Tactile feedback needs 0.1mm resolution for dexterous manipulation, while SLAM (Simultaneous Localization and Mapping) demands millimeter-accurate spatial awareness.

What standards govern humanoid safety specifications?

ISO 13482 establishes core requirements including speed/force limitations, impact detection thresholds, and emergency stop protocols. Additional certifications include:

UL 3300 for systems operating near people

IEC 61508 SIL 2 safety compliance

Region-specific workplace regulations