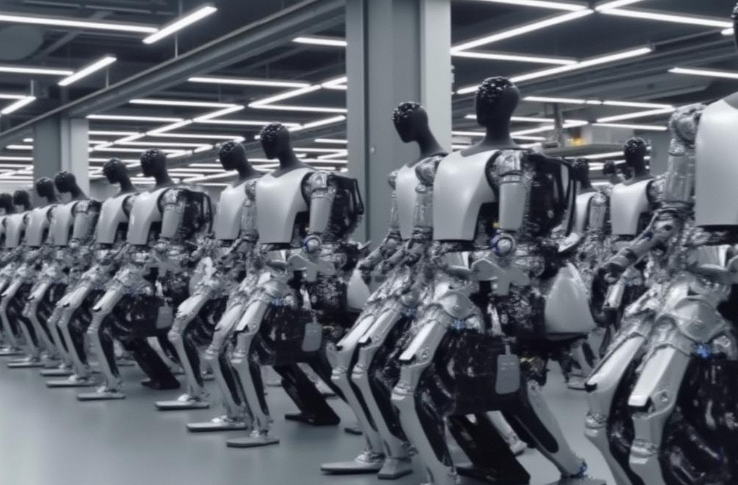

Tesla's Optimus Factory Deployment is set to revolutionize the automotive industry by integrating advanced humanoid robots into production lines. With 500 Optimus bots already enhancing battery module assembly, Tesla is paving the way for smarter, safer, and more efficient manufacturing processes. This guide dives into how Optimus transforms factories, the tech behind its deployment, and what it means for the future of automation.

Why Tesla's Optimus Factory Deployment Matters

Tesla's decision to deploy Optimus humanoid robots in Gigafactories isn't just about tech hype—it's a strategic move to address labor shortages, reduce production costs, and boost output. By 2025, Tesla aims to deploy 1,000 Optimus robots across its facilities, with plans to scale to 500,000 units by 2029 . These robots aren't just for show; they're engineered to handle repetitive, hazardous tasks like battery module assembly, welding, and material handling—areas where human workers face risks like repetitive strain injuries or exposure to toxic materials.

The real game-changer? Optimus leverages Tesla's proprietary AI frameworks, including Full Self-Driving (FSD) chips and the Dojo supercomputer, to learn and adapt in real time. This means robots that improve with every task, making them indispensable for industries chasing precision and scalability .

Tesla Optimus Factory Deployment: The Tech Behind the Revolution

1. AI-Driven Precision

Optimus bots are equipped with multi-camera vision systems and FSD chips that enable them to navigate dynamic environments. For battery assembly, they use LiDAR and 3D scanning to align components with ±0.01mm precision—far surpassing human capabilities . This precision minimizes defects and ensures consistency in high-stakes tasks like welding battery cells.

2. Modular Design for Flexibility

Tesla's modular approach allows Optimus to swap tools and adapt to new workflows. For instance, a robot handling battery tray assembly in the morning can switch to quality inspections by afternoon. This flexibility reduces downtime and makes Optimus a versatile asset across factories .

3. Energy Efficiency

Optimus runs on Tesla's 2.3kWh battery packs, optimized for 24/7 operation. The design uses 21700 lithium-ion cells (similar to Model 3 batteries) with a 52V nominal voltage, enabling extended runtime without frequent recharging . Heat dissipation is managed via integrated cooling fins and fans, ensuring stable performance even during heavy workloads.

Step-by-Step: How Optimus Enhances Battery Module Assembly

Material Transport

Optimus transports battery cells and modules using its 11 degrees of freedom arms. Its grippers adjust to different shapes, reducing human intervention in logistics.Cell Positioning

Using AI-guided vision, Optimus aligns cells with 0.1mm accuracy, critical for avoiding short circuits. Thermal cameras monitor temperature to prevent overheating.Welding and Assembly

Equipped with laser welding tools, Optimus joins cells into modules. Its force-sensing joints apply consistent pressure, ensuring joint integrity.Quality Control

Built-in sensors test electrical conductivity and insulation. Data is fed into Tesla's Dojo AI for real-time analysis, flagging defects instantly.Pack Integration

Completed modules are stacked into battery packs. Optimus uses RFID tagging to track each unit, streamlining inventory management.

Challenges and Solutions in Optimus Deployment

1. Initial Costs

Optimus bots cost 30,000 each, but Tesla plans to slash prices via economies of scale. Early adopters benefit from tax incentives and reduced labor costs over time .

2. Workforce Adaptation

Factories are retraining staff to work alongside Optimus. Programs focus on AI oversight and robot maintenance, turning potential job losses into new roles.

3. Technical Hurdles

Software glitches and sensor calibration remain issues. Tesla's Dojo supercomputer trains Optimus via simulated environments, improving its problem-solving skills .

The Future of Humanoid Robots in Manufacturing

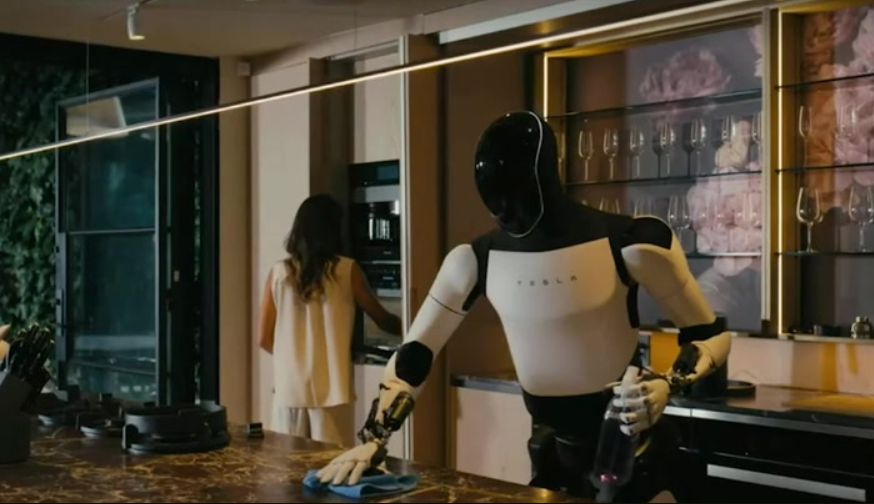

Tesla's Optimus isn't just a factory tool—it's a blueprint for AI-human collaboration. Future iterations could handle delicate tasks like painting or electrical system installation. Beyond automotive, Optimus could revolutionize healthcare (e.g., assisting surgeons) or logistics (e.g., warehouse logistics) .

FAQ: Tesla Optimus Factory Deployment

Q: Are Optimus robots safe around humans?

A: Yes! They use collision detection and predictive movement algorithms to avoid accidents.

Q: How long does Optimus take to learn a new task?

A: With Dojo's training, tasks like battery module assembly can be mastered in <24 hours.

Q: Will Optimus replace human workers?

A: No—it's designed to handle repetitive roles, freeing humans for creative and supervisory tasks.