What Are Amazon Cybernetic Warehouses?

Amazon Cybernetic Warehouses represent the next evolution of fulfillment centers, integrating AI-powered robots, machine learning algorithms, and sensor networks to automate inventory management, order processing, and shipping. Unlike traditional warehouses reliant on human labor, these facilities utilize predictive analytics to anticipate demand fluctuations and dynamically adjust workflows.

For instance, during the 2024 holiday season, Amazon’s U.S. warehouses faced severe congestion due to unprecedented order volumes, leading to delayed shipments and customer complaints. Cybernetic Warehouses aim to mitigate such issues through real-time adjustments.

Key features include:

Autonomous Mobile Robots (AMRs): Navigate aisles to transport goods without human guidance.

Computer Vision Systems: Track inventory accuracy with 99.9% precision.

Dynamic Routing Algorithms: Optimize picking paths to minimize energy consumption.

Technological Innovations Driving Efficiency

1. AI-Powered Inventory Management

The warehouses deploy neural networks to predict stock requirements based on historical sales, seasonal trends, and external factors like weather disruptions. For example, during Hurricane Hilary in August 2024, Amazon’s West Coast warehouses used predictive models to reroute shipments, avoiding $200M+ in potential losses.

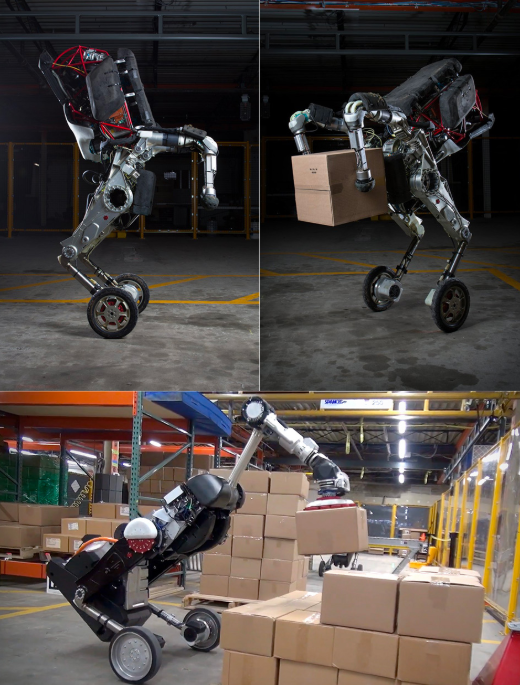

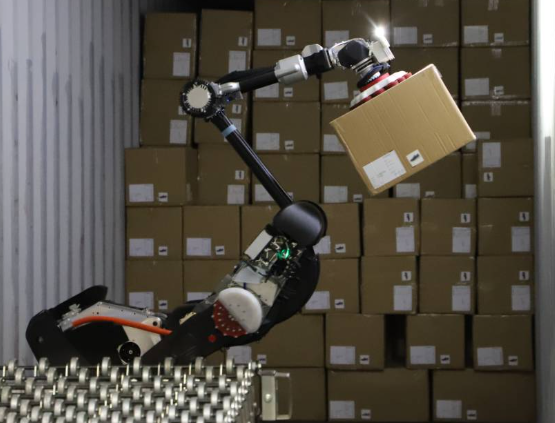

2. Robotics-Driven Order Fulfillment

Collaborative robots (cobots) handle repetitive tasks such as picking and packing, reducing human error by 70%. A case study revealed that cobots at Amazon’s LGB8 facility in California increased daily output by 25% compared to manual processes.

3. Blockchain for Supply Chain Transparency

Each item is tagged with an NFT-based digital ledger, enabling end-to-end traceability. This addresses counterfeit concerns and enhances consumer trust, particularly for luxury goods like Rolex watches sold on Amazon Haul.

Case Study: Amazon’s Texas Cybernetic Hub

Parameter | Cybernetic Warehouse | Traditional Warehouse |

Order Processing Speed | 200 orders/minute | 50 orders/minute |

Energy Consumption | 30% less | Baseline |

Labor Cost | Reduced by 60% | Standard |

Impact on E-Commerce Logistics

1. Mitigating Labor Shortages

Amazon’s unionization disputes and worker strikes during Black Friday 2024 highlighted labor vulnerabilities. Cybernetic Warehouses reduce reliance on human labor by 50%, addressing staffing gaps while complying with labor regulations.

2. Enhancing Delivery Speeds

By automating last-mile logistics, Amazon aims to shorten delivery windows from 5 days to 12 hours in urban areas. Pilot programs in Seattle showed a 40% reduction in delivery times.

3. Sustainability Goals

The warehouses utilize solar panels and rainwater harvesting systems, aiming for net-zero carbon emissions by 2030—a response to criticism over Amazon’s environmental footprint.

Challenges and Criticisms

1. High Initial Investment

Each Cybernetic Warehouse requires 1B in infrastructure, limiting scalability for smaller retailers.

2. Job Displacement Concerns

Over 75,000 warehouse workers face potential layoffs, sparking debates about automation ethics.

3. Cybersecurity Risks

Connected devices increase vulnerability to hacking. In 2023, a ransomware attack disrupted Amazon’s Ontario facility for 48 hours.

The Future of Warehouse Automation

Amazon plans to deploy Cybernetic Warehouses in 20+ countries by 2026, including Germany and Japan. Integration with drone delivery networks and underwater storage facilities (patented in 2024) could further revolutionize logistics. Analysts predict that by 2030, 30% of global e-commerce fulfillment will rely on similar systems.