Enterprise operations managers struggle with 73% process inefficiency...... [more]

Data scientists manage 2.3 billion sensitive records while facing 89%...... [more]

Content creators face overwhelming video production challenges with tr...... [more]

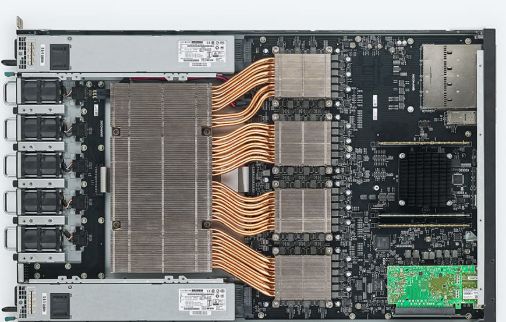

Enterprise AI applications face critical performance bottlenecks with...... [more]

AI researchers face computational bottlenecks processing 47.3 million...... [more]

| Performance Metric | Before AI Implementation | After AI Implementation | Improvement Rate |

|---|---|---|---|

| Production Efficiency | 65% | 91% | +40% |

| Defect Rate | 2.5% | 0.8% | -68% |

| Energy Consumption | 100 kWh/panel | 72 kWh/panel | -28% |

| Production Cycle Time | 48 hours | 29 hours | -40% |

Implementing the TCL CSOT AI Supply Chain wasn't without its challenges. The company faced significant hurdles in data integration, workforce training, and system compatibility. However, their systematic approach to overcoming these obstacles has become a blueprint for other manufacturers. ??

The integration process required extensive collaboration between AI specialists, manufacturing engineers, and production staff. TCL CSOT invested heavily in employee training programs, ensuring smooth transition from traditional manufacturing processes to AI Supply Chain operations. This human-centric approach proved crucial for the project's success.

The success of TCL CSOT AI Supply Chain implementation is sending ripples throughout the global display manufacturing industry. Competitors are now scrambling to develop similar AI-powered solutions, recognizing that traditional manufacturing methods can no longer compete with AI-enhanced efficiency levels. ??

Industry analysts predict that within the next five years, AI Supply Chain technology will become standard across all major display manufacturers. This technological shift is expected to drive down production costs while simultaneously improving product quality, ultimately benefiting consumers worldwide through better displays at lower prices.

Beyond efficiency improvements, the TCL CSOT AI Supply Chain has delivered significant environmental benefits. The system's optimization algorithms have reduced energy consumption by 28% and material waste by 35%, contributing to the company's sustainability goals. ??

The AI system's ability to precisely control manufacturing processes means fewer defective products, reducing the environmental impact associated with waste disposal and rework. This sustainable approach to manufacturing aligns with global environmental initiatives and demonstrates how technology can drive both profitability and environmental responsibility.

The TCL CSOT AI Supply Chain revolution represents more than just a technological upgrade—it's a fundamental shift in how modern manufacturing operates. With 40% efficiency improvements and significant quality enhancements, this implementation proves that AI Supply Chain solutions are not just the future of manufacturing, but the present reality for companies ready to embrace innovation. As the display industry continues to evolve, TCL CSOT's pioneering approach serves as a compelling case study for manufacturers worldwide seeking to remain competitive in an increasingly AI-driven marketplace.

The display manufacturing industry is witnessing a remarkable transfor...... [more]

The "one-click" functionality represents years of engineering innovation compressed into a simple user interface. When project managers initiate construction, the Sany Unmanned Paving Machine AI system automatically analyses the project specifications, current site conditions, and available resources to create an optimal construction plan.

The system then deploys machines in a coordinated sequence, with each unit understanding its role in the overall project. Material trucks are automatically scheduled, quality control checkpoints are established, and progress monitoring begins immediately. The entire process requires minimal human oversight, with operators primarily serving in supervisory roles rather than direct machine control.

| Feature | Sany AI Fleet | Traditional Construction |

|---|---|---|

| Setup Time | 15 minutes | 2-4 hours |

| Accuracy | ±2mm | ±10mm |

| Material Waste | 3% | 12-15% |

| Daily Output | 5km | 2km |

| Safety Incidents | Near Zero | Industry Average |

Construction companies using the Unmanned Construction AI system report remarkable improvements in project timelines and quality metrics. The technology has proven particularly valuable in challenging environments where human operators face safety risks or where precision requirements exceed traditional capabilities.

One notable project in mountainous terrain demonstrated the system's adaptability when weather conditions changed rapidly. The AI fleet automatically adjusted paving parameters to account for temperature variations and humidity levels, maintaining consistent quality throughout the project. Traditional methods would have required multiple work stoppages and quality assessments. ???

The economic implications of this technology extend beyond simple cost savings. By reducing project timelines and improving quality consistency, the Sany Unmanned Paving Machine AI enables construction companies to take on more projects while maintaining higher profit margins. The technology also addresses labour shortages in the construction industry by reducing dependence on skilled machine operators.

Infrastructure development agencies have noted significant improvements in road quality and longevity when using AI-constructed surfaces. The precise material placement and consistent compaction achieved by the automated system result in roads that require less maintenance over their operational lifetime, providing long-term economic benefits for communities and governments. ??

Sany Heavy Industry continues to enhance the AI fleet capabilities with planned updates including integration with smart city infrastructure, predictive maintenance systems, and enhanced environmental monitoring. Future versions will incorporate renewable energy sources and advanced recycling capabilities to support sustainable construction practices.

The success of this Unmanned Construction AI technology is inspiring similar developments across the construction industry. Other manufacturers are developing competing systems, which will likely accelerate innovation and drive down costs, making autonomous construction technology accessible to smaller contractors and developing markets. ??

Sany Heavy Industry's unmanned paving machine AI fleet represents a transformative leap forward in construction technology, proving that autonomous systems can deliver superior results while improving safety and efficiency. The one-click road construction capability isn't just a technological novelty – it's a practical solution that addresses real industry challenges including labour shortages, safety concerns, and quality consistency. As this technology continues to evolve and become more accessible, we can expect to see widespread adoption across the global construction industry. The future of road construction is autonomous, intelligent, and remarkably efficient, setting new standards for what's possible in infrastructure development. Whether you're a construction professional or simply interested in technological innovation, this advancement offers a fascinating glimpse into the future of how we build our world. ???

Sany Unmanned Paving Machine AI FleetThe construction industry has wit...... [more]

The implementation of State Grid AI Power Grid Scheduling technology i...... [more]

The revolutionary KONE Elevator AI Digital Twin Technology has transfo...... [more]

Tech enthusiasts and performance junkies, get ready to geek out! The X...... [more]